Here’s a really cool new technology. Put on your thinking caps and let’s see if we can figure out a cool use involving our Glowforge. http://www.sciencealert.com/watch-the-tricks-you-can-do-with-these-crazy-next-gen-magnets-will-blow-your-mind

Wow! That is incredible!

The simplest use for us would be locking mechanisms on boxes. I think it would also be possible to make cogs and gears with these too.

That

Is

Amazing

This would be perfect for holding catan tiles together with magnets, as you could have a positive and a negative next to each other on the same side. That way every tile would would be able to connect to the others on every side.

Marvelous Innovation!

programmable, configurable magnetic poles!

Thanks for that!

One of the biggest innovations I have seen in a while!

Maxels? Super cool. Thanks for sharing!

The guys from Polymagnets just did an AMA on reddit yesterday!

You can do this considerably easier by using cylindrical magnets polarized through the radius. Then the magnet just rotates to the appropriate alignment to mate with the selected neighbor.

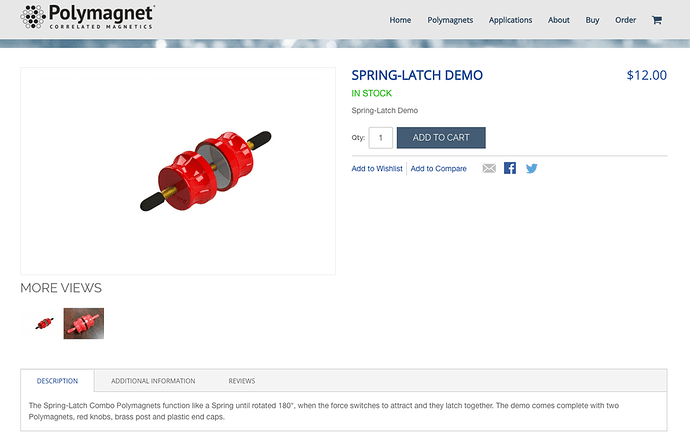

But yes… using the latching polymagnets on the lid so that:

- It is impossible for the lid to slam down hard (magnetic braking)

- You can securely latch the lid closed

That would be pretty sweet.

aye, but sometimes they get a little finicky, and sometimes they dont want to turn, and then sometimes depending on the strength they ALL have to turn which is a problem when a piece is connected on the other side. Ive found the spheroid ones work better than the round flat magnets, but if I were able to have stationary magnets that would be preferable

This has the potential to be a game changer for sure! Maybe they should figure out how to put those spring ones into the bottom of a maglev train and have the track’s fields morph appropriately to keep the spring effect working as it moves - it would hold the train up and down at the same time! So cool!

Hmmm…

air-hockey table, but with no air. The puck always floats but never flies off the table.

mag-lev matchbox cars and track… again, the cars float for a frictionless glide, but don’t go flying off the track.

mag-hinges that never squeak.

door-knobs that don’t require a spring and can’t get gummed up… (although we had mag-locks on the doors of an apartment building in college, and quickly figured out that you didn’t need the keycard… just yank REAL hard  )

)

this is really cool.

Trying to imagine its use in electric motor locomotion.

Supper cool’

A magnetic bearing might be easily possible by placing alternating rows of positive and negative poles along the inside periphery of the bearing from front to back and an identically spaced series of alternating rows on the shaft. A sheath would cover the shaft until positioned and removed from the end when done.

Or you could just have 2 magnets on each side of the hex, one being a north and one a south.(so it goes NS,NS,NS,NS,NS,NS in a clockwise fashion on all pieces) But you wouldn’t be able to have double sided pieces

does anyone have a contact number for these guys. trying to source them in the UK, but no joy and my somewhat specialist needs means a phonecall would be quicker and more useful than an email enquiry (but I can’t find a contact number on their website).

Not enough room inside of a bearing to allow this to work with any real weight involved I don’t think. Sleeve bearings are close to what you are talking about. They ride on a thin layer of oil and can move left to right upon startup and find their own “magnetic center”. Big problem with sleeve bearings are they don’t do well with up and down movement. One little scuff and they start to heat up and melt. I would see the same problem in a magnet bearing, might be good for stationary jobs but not one with any up and down movement.

I have rebuilt tons of sleeve bearing motors and more often than not our customers request we build new housings to make them roller bearings.

I definitely like the idea of making box latches. I wonder how small you can get these?

Haha I may have to do the same, pretty cool stuff.