Oh, I like that! It’s got my mind racing on adapting the design to look like my 1952 Willys truck or any number of other classic cars and trucks.

Go for it! Also, we should put wheels on the trebs so that @polarbrainfreeze’s hot rods can tow them.

Nice!

As soon as I get done with my current project- I design and post my idea.

Do you have a picture of your truck? Or an image on Google that looks like it?

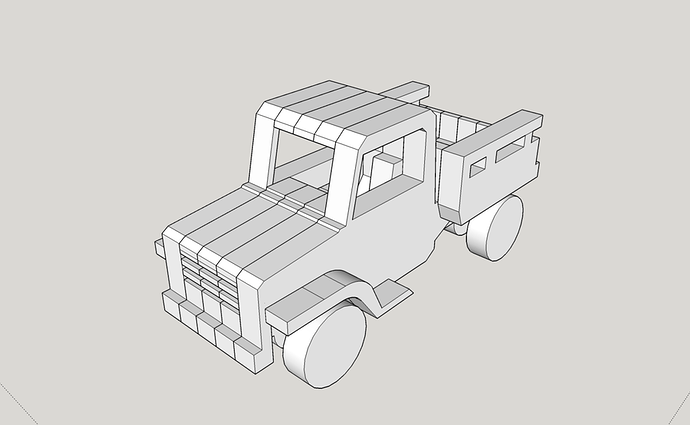

If I find the time, I’ll probably design another one or two different cars to fit on the same sheet.

This is my truck…

Here’s a Skechtup model of a similar truck. I used this model to cut a 2.5D sign on my CNC router.

Here are other angles of other 52 Willys trucks.

https://www.google.com/search?q=1952+willys+jeep+truck&espv=2&rlz=1C1CHWA_enUS633US633&biw=1920&bih=911&tbm=isch&tbo=u&source=univ&sa=X&ved=0ahUKEwj8k6yApa_NAhUIcj4KHWT2CyUQsAQIKQ

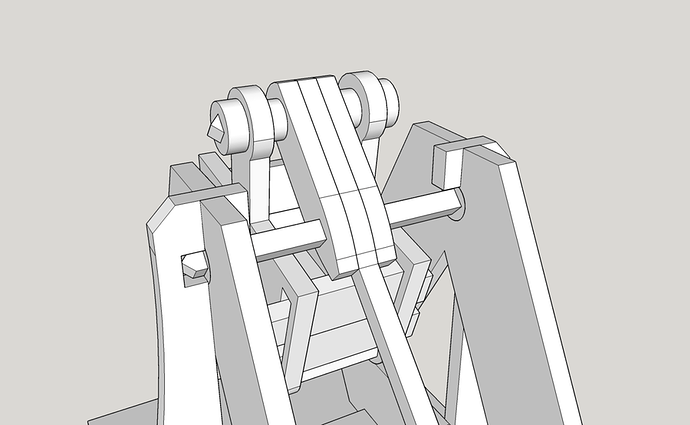

It turns out that converting mine to work without the pencil was not much trouble. I just swapped in square axles with Chinese coin style collars on them to give a round surface to pivot on at the necessary spots.

And just not adjusting for kerf on the round discs and holes should give it enough play to rotate freely.

ETA: the larger collars on the outside ends of the smaller pivot are just to keep it from walking side to side.

I was thinking of doing the same thing for the axles on my car design, so it can all be cut on the GF. But I’m afraid the “square” axle will grab the elastic when the car is moving forward. I wanted something a little more round.

If I had a laser at home, I would try it with the round pencils and the square laser-cut axles and see if they both work.

They can’t. But the fun is finding a way to make functional axles with a laser ![]()

I suppose you could made enough stacked “coins” to make a fully round axle where the rubberband wraps, though it might make it too beefy for your current design scale (mine are about 1/2"D so ~30% bigger than a pencil.)

That’s great!

On our way to pumpkin chunkin!

All we need now are some buildings for the trebuchets to launch an attack on…

How about that first cardboard design without the kerf? Worth chucking some laser-cut critters at, I think?

Hahaha oh man, totally worth it! Though if I still have that damn rhino file I have zero idea where it would be  I might have some other ideas on the drawing table though…

I might have some other ideas on the drawing table though…

That is very clever.

I would strongly suggest cutting a bit big and giving all the bearing surfaces a light sanding in the direction of rotation. Even a super accurate laser cut introduces regular roughness along the axis of the laser*. Matching two such surfaces as a bearing is going to have a lot of friction, and sanding in the opposite direction will help.

(*verified empirically)

You beat me to it @likeablejerk.

Here’s the one I made at lunch time.

I like how you did the grill on the front of yours, and the back “gate”. I actually used a separate piece for my grill, but your design is simpler. I’ll have to adjust my design to do something similar.

Awesome!

Some combination of the two would work.

You know, if we did this with stacked 1/8" stock instead of 1/4", we could put quite a bit of detail in it that otherwise looks too chunky (including the seam of the split windshield.)

This kinda makes me want to do a laser-based pinewood derby.

I like the 1/8" idea. But it limits how many cars I can fit on one sheet (remember, the competition rules say “one sheet of material”). BUT if we are talking about things outside the competition, then I’m all for it.

In fact, we could use a combination of 1/4 and 1/8. Have 1/4" things in the middle, and 1/8" pieces on the side. You could make much nicer tires, and you could have nice details on the sides.