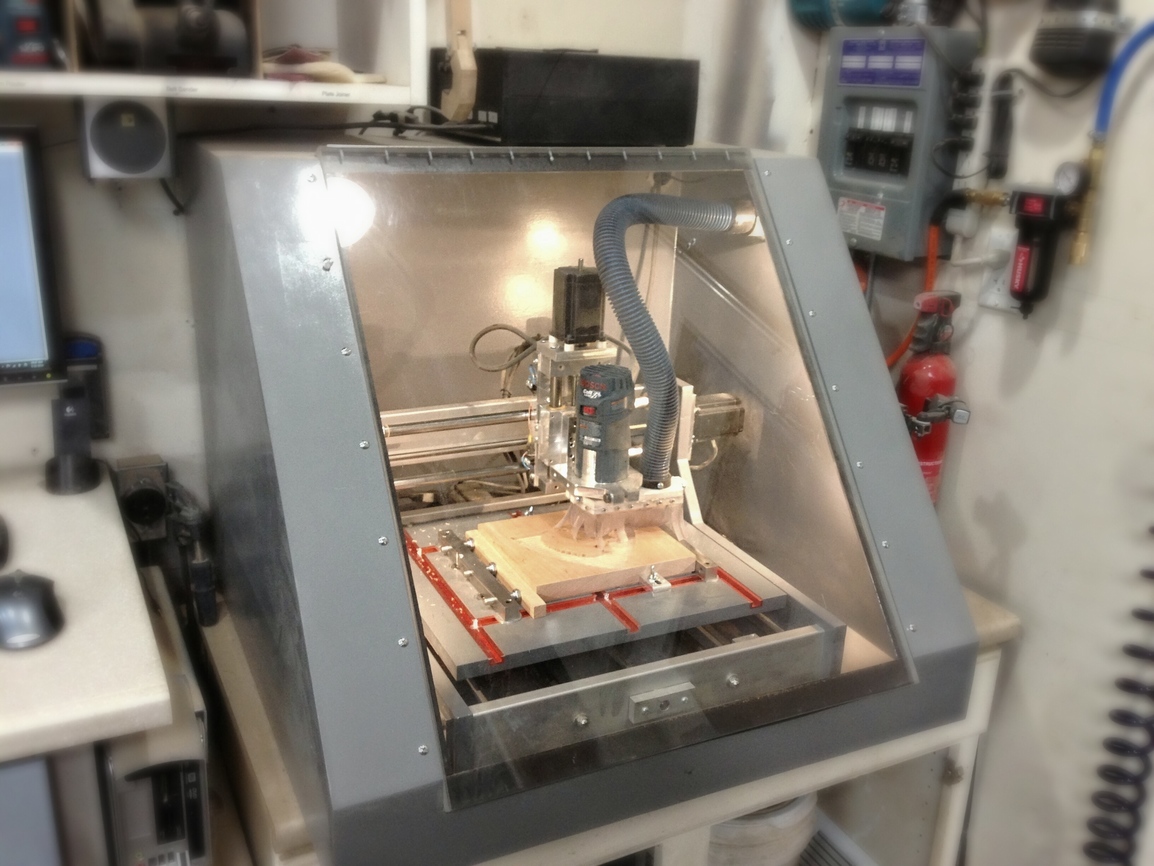

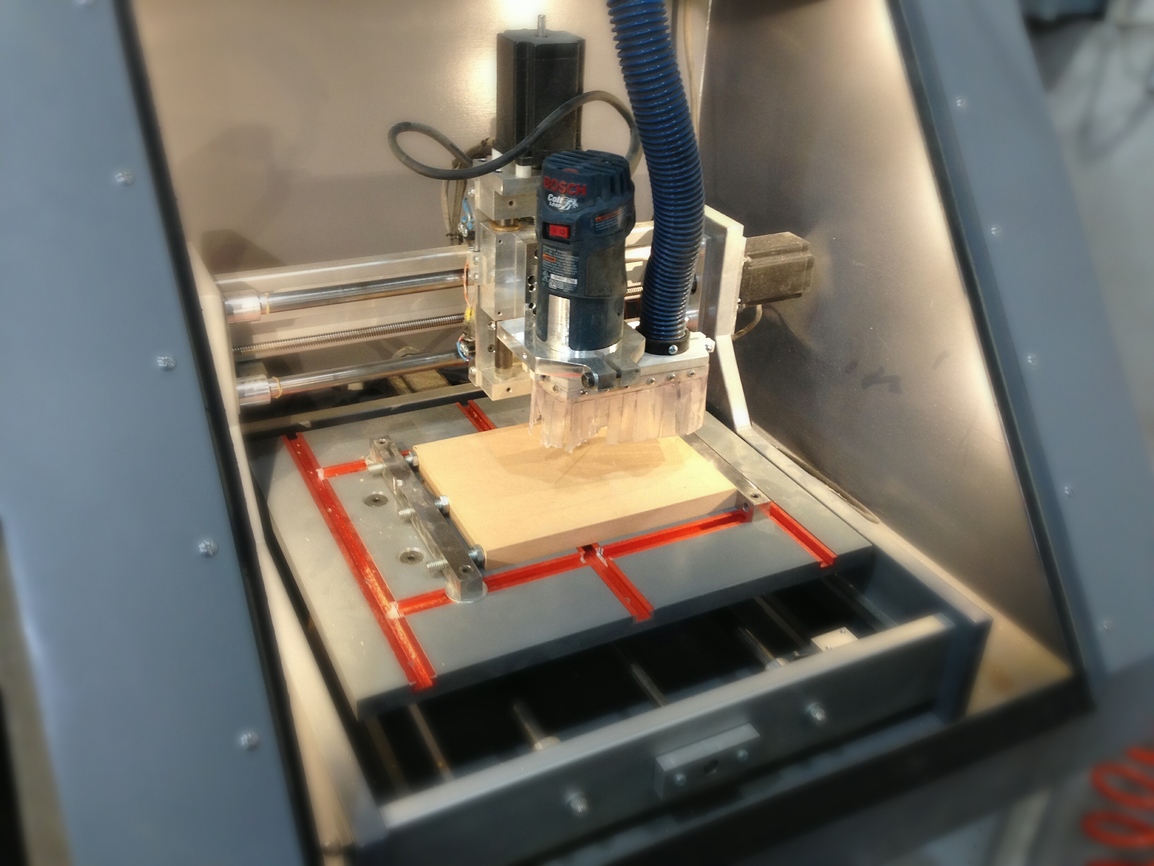

I’m with you @dan, I love my desktop CNC router. Here are a few pics of my"desktop" CNC router I designed and built a while back. Of course if you are going to have a desktop CNC machine it has to have an enclosure :). I can upload the Solidworks files if anyone is interested.

I have to preface this post by saying I was a little hesitant to post these photos. The photos and techniques are quite old and I have made a lot of changes and improvements. (I know that no one really cares, but sometimes I get a little self conscious ![]() ) Anyway, they are kind of fun.

) Anyway, they are kind of fun.

My little prototyping machine. Sits on a desk and doesn’t make a mess… or at least not a very big mess.

The dust skirt is held on by neodymium magnets and can quickly be removed.

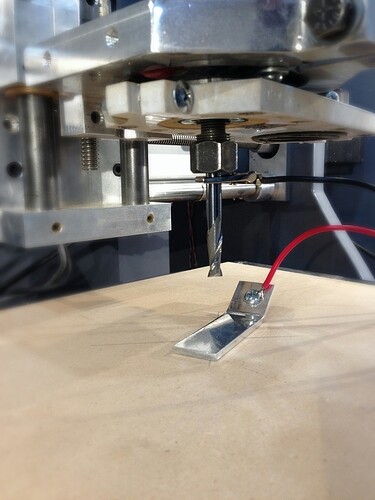

Electronic zero plate makes it easy to quickly set height of the Z-Axis cutter.

You can see my quick and dirty clamping solution. It has actually proven to be quite convenient and fast.

It also had its own Skype address so I can keep an eye on it from anywhere. Not the safest thing, but it sure is fun.

The enclosure as well as the side panels of the CNC machine are made out of MDF.

All painted up and lit with some LED lighting.

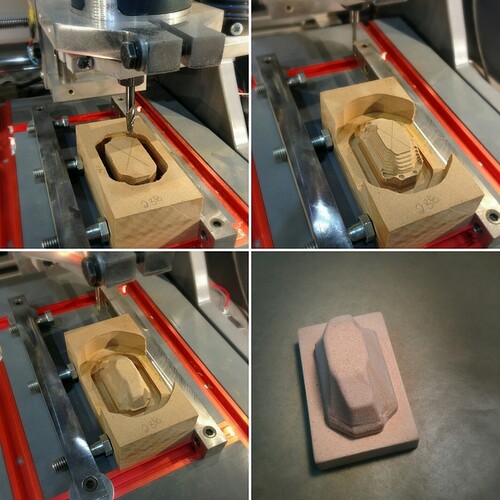

I use the CNC machine to make buck molds for the desktop vacuum former that I designed and built (I know, I know, I am a super nerd, but I love it!).

Testing out my proof-of-concept thermoformer/vacuum former.

I have found that MDF is a cheap and easy material for creating buck molds for the vacuum former, especially when I am just prototyping. I seal it with a sanding sealer and it gives it a nice hard glossy coating.

More buck molds. My desktop vacuum former is 100 times more valuable in combination with the desktop CNC.

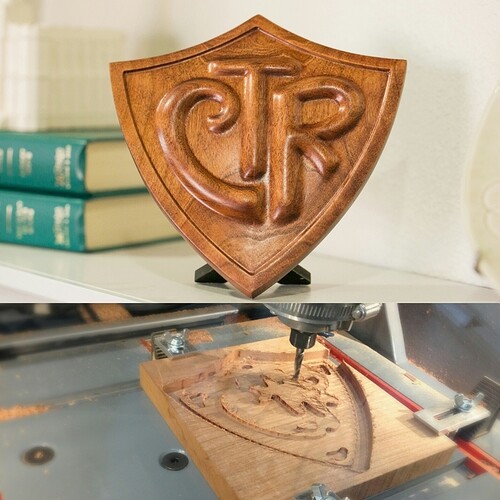

Here is a finished product and an “in progress” shot.