I ordered a sample kit online too, and got a call on Monday asking for more detail on what I planned to do with the material. Did they call you too?

No. Maybe I should look forward to one? Thanks for the heads up, though…that will give me time to think of an answer.

What kinds of questions did they ask you?

My guess is something along the lines of, “You wouldn’t happen to know why we received more requests for samples in a day than we normally receive in a year do you?”

I just ordered a sample pack as well and will put it though the paces on my other lasers when it comes in… ![]()

Fantastic! I will look forward to hearing how they work out.

Oh…ha ha! Yeah, I guess that would make them sit up and take notice. Well, I’ll be ready no matter what, but I’m guessing whatever your reply was, was enough to satisfy their curiosity. Thanks.

When asked, I told them that it would be used for laser engraving, which seemed to confuse her. She then wanted to know which materials I wanted samples of but I was not near a computer and told her that I would call back. I won’t do that until the Glowforge arrives and I get a better feel for what sorts of projects I want to use the GF with.

I am supposing that these samples would be similar to anodized aluminum…at least as far as lasering goes, but I know that remains to be seen. Since this is a UK company, it wouldn’t surprise me if they didn’t want to send sample packs out to people in the US.

It might be, but I would not expect that actually as they are very different processes.

Anodized Aluminum is colored by soaking a dye (or dyes) into a fairly thick layer of electrochemically grown Aluminum Oxide. The colors you can get are almost infinite, and they are protected by the oxide itself. When you hit it with a laser you are (I think) removing some of the oxide and bleaching out the dye.

Stainless does not work like that which is why the colors they can produce are so limited. In that case what you see is most likely the result of light being diffracted through a very thin layer of metallic oxides (more like the colors in a soap bubble). This is also what make the coloration on Titanium.

It will be very interesting to see what happens when you hit that layer with a laser…

They have an office in the US apparently too…I was able to choose US delivery

How cool is this? I just received my sample pack of Rimex! You were right, smcgathyfay; [quote=“smcgathyfay, post:32, topic:100”]

They have an office in the US apparently too.

[/quote] They were shipped from New Jersey. Lovely little presentation case. Here’s what it looks like. Hmm…now if only I had a laser…![]()

And thank you jkopel…I always trust your infinite knowledge. smcgathfay said they will use one of their ‘other’ lasers to see what will happen with the Rimex and I too look forward to hearing about that experience.

Very cool little presentation of samples!

Don’t be too trusting… That is a little different then I thought from looking at their web site. It almost looks like some of them have a thicker patina on them. What does the sample in the lower right look like outside the case?

oooh pretty things to play on… can’t wait!! lol

Difficult to photo without reflection or in a light that can show the true color…and this photo does not do it justice. It’s pretty, though.

<img src=“//cdck-file-uploads-global.s3.dualstack.us-west-2.amazonaws.com/glowforge/original/2X/6/6ef407d5e0bce0fbae7c09c65afc0ce4d11dce2e.JPG” width=“690”

A rose gold color. The samples are extremely difficult to slide out of their little compartments and at least two of them are slightly concave rather than rounded and smooth like the others. Just slightly smaller than a business card. Beautiful colors. Could be exciting. This is the reverse of the sales person’s business card that was included.

Thanks, I am going to stand by my earlier guesses until proven otherwise.

The electro-chemical process is probably one that oxidizes the SS directly. The PVD Titanium bit is interesting. It means they are actually depositing a thin layer of Titanium on the stainless and then coloring that. Might be very thin, and I wonder what the laser will do to it.

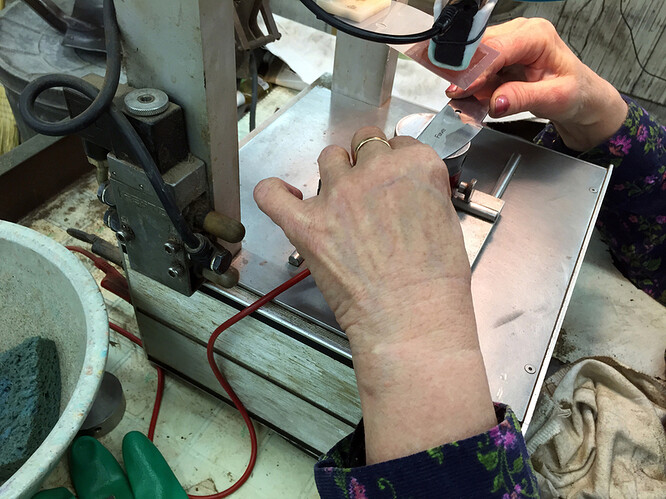

We use the electro chemical process on our knife blades:

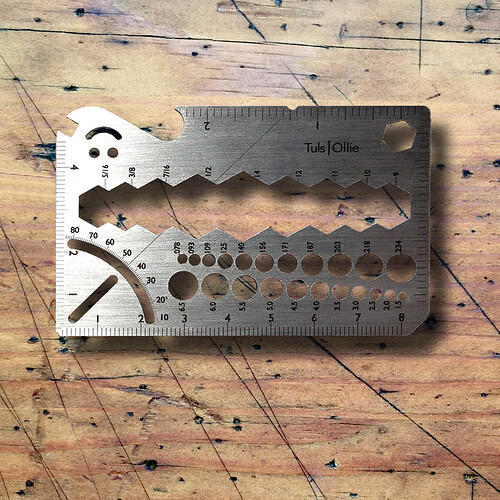

Our tools are marked with a YAG - mark turns out nice and black when done right:

Thanks… a 150 year old knife company produced our design and we used reclaimed wood for the ‘scales’ (knife-speak for handles)

Beautiful knives!

How well did these work!?