- 5 Axis laser. The cameras are already there. 3D imaging seems to be there to at least a degree. Next logical step: increase the chamber Z size. Place any object in there of any shape. GF does 3D scan. User does design on 3D object. GF engraves / 3D cuts the object from any angle. Like this: https://www.youtube.com/watch?v=5Hp_DPEapzg

– - Thermal cameras. So we know how hot things get. Do post-mortems on failed cuts / flashes.

– - Fire suppression capsules. The thermal imaging data could report on unusual heat signatures for particular materials and shut down. But the material could already be on fire at this point. If so, the capsule releases and kills the fire.

To avoid this…

– - Filter & Vent Combination:

A both-and approach for venting already filtered air for a cleaner environment inside & out. And less smelly again both inside & out. 2" vent pipe in this case should suffice, which is less obtrusive.

Your point #3 raises a good question. I know that the GF plastic is said to melt, not burn. The same can’t be said for the materials we are cutting. I know that a laser cutter is also a tool you don’t start and then walk away from. So, should a fire start in a laser cutter that is not a typical controlled burn, what is the proper way to extinguish without damaging the unit. Portable halon fire extinguisher? A can of compressed CO2, like for blowing dust out of electronics?

The reality is that there will be moments, even seconds when one’s attention is drawn away (my new neighbor is a stunner! I had to buy a GF to appease my wife who noticed me noticing her. We’re ok for now). It’s great that the plastic ‘only’ melts but there goes my $4K investment up in smoke. My little girl cries. The dog barks. The smoke alarm whines. I cry. The new girl from next door comes knocking. It’s just a dangerous situation all round.

I will also get a portable extinguisher for sure (manual extinguishing of laser fires deserves a whole topic of its’ own). However, the point of the post is that it is a future feature suggestion. Inergen gas or similar in a small capsule with a thermal release valve could work very well. Remote access to the camera could also help in this case (not available yet is my understanding).

For fire extinguisher, you want to buy a CO2 extinguisher, since you will be splashing anything you spray in there onto circuitboards, and basically any other type of extinguisher than CO2 is bad news for exposed circuitry.

For each of the requests, you are shifting the machine into another pricing tier. So I would classify the requests as being aimed at GF 2.0, or just a new machine completely.

- While the camera (basic cellphone) is in place, the motors and frame size is not. Of course requesting a different size chamber already made this a clear “next model” request. But to do full 3D carving means adding another three motors on the cutting head (head up/down, and head rotate parallel to Y axis, head rotate parallel to X axis). The rotations of the head would actually require two motors each, or some ingenious gear solution, since the mirrors need to be aligned with incoming beam and focusing lens. I do know that there are laser cutters which can do this, so it is a solved problem. But the laser cutter I know of is for a high end car (I believe it was Lexus) manufacturing their dashboard, so likely an insanely expensive machine (though much of that for being large enough to fit an entire dashboard inside it, and likely mobile enough to fit inside of the car instead of enclosing the dash)

2 & 3) Thermal camera prices have come down a fair amount. Off the top of my head (with bad memory) I think the FLIR breakout is around $130. But if you want to react to the camera data, that also requires onboard computing power. Having to wait for latency on sending images to the cloud for processing and having commands come back is not a solid fire-suppression plan. So overall, this would add a minimum $500 to the price alone (no clue what the capsules cost). Which isn’t particularly a bad investment since it is about safety.

What I like about Glowforge is that they are introducing entirely new functionality into a market that has been sitting on the same old features for 30 years. And they’re doing it at at a more accessible price. So why stop there?

While some of these features have traditionally been expensive and inaccessible to the average maker, Glowforge have showed that they can change that. These suggestions are indeed aimed at GF 2.0 and onwards. I hope to see all of these at some point in future, along with some others.

Any other ‘future freature suggestions’? Stretch your minds people. Remember, there is no spoon…

Local connection capabilities - even if it means using it only allows for file based printing and doesn’t allow for the catalog function.

I agree, also for the camera.

My biggest hope for future models is more Z height. I wouldn’t mind more X and Y, but the Z opens up many more potential applications.

I am curious what it would be like to incorporate a CNC mill into the laser housing. Figuring out how to handle the waste material would be a major trick there, but if you could cut away bulk material with the CNC, and then refine edges with the laser, that would enable doing some much more impressive work considerably quicker.

Recent developments like the Walabot may mean that one day it is possible to scan the material and set the laser parameters directly. Not for that material type in general, but for that specific piece in the machine right now, with local humidity and temperature conditions accounted for.

Added filter & vent combo to original list…

Link to this baby added to original 5-axis note: https://www.youtube.com/watch?v=5Hp_DPEapzg

That would be amazing for a future Glowforge…

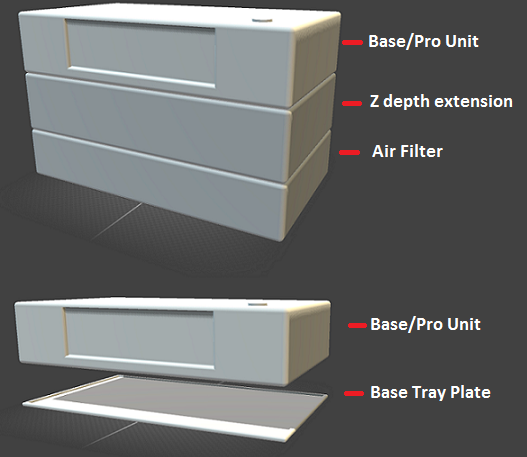

I agree with you on the Z height as being nice to have for version 2. I read that they mentioned increasing size would balloon the shipping cost. But what if they sold and shipped z height separately like they already do with the air filter? I’m sure there would be a few of us that would pay a few hundred dollars for an accessory like that (next version of course). I did a quick sketch to try and convey how I envision something like that to stack. Of course if someone just purchased a basic unit, they would need a removable floor for upgrade options:

I like these ideas. Fire suppression could also be helped with stronger air assist and ventilation. Like the ventilation and doors seal, sucking out all the oxygen, and bam, no flame.

Things I have seen with other laser systems that I would like to see are more software based - like pause and resume, material database with suggested power and speed settings, ability to tell it to engrave from bottom up or top to bottom, etc.

I’d also love that z extension and possible rotary attachment in the future.

Love this idea. As for moving the piece on the Z-axis, which is better: movable height cutter head or a platform that can raise and lower smoothly?

In general there is not much difference. Long term it will depend on how well you care for the machine.

Movable bed you typically have a lot more height variance available. Movable head and you have a more reliably level bed over the life of the machine (if you are slack about maintenance). Movable head is probably less total power consumption, not that you will be moving your height all that often for power to really matter.

Movable head with large Z height variance available will mean large head flying around, means more chance of it running into something, or being damaged when it does so. Also means you need stronger motors for your XY travel, and don’t get as much speed from their extra power.

So… I guess re-reading my analysis, movable bed looks like a clear winner. But remember to keep your screws or whatever is used to move the bed well maintained so it remains nice and smooth moving (and thus hopefully level)

Once I saw this Mitsubishi VZ10 video, I started to think that maybe a head with a lot of mobility might beat the moving bed after all. ![]() It would be nice to be able to raise the base though to allow larger pieces even if the laser retained a 2 inch focusing distance.

It would be nice to be able to raise the base though to allow larger pieces even if the laser retained a 2 inch focusing distance.

Heh heh. Yeah, that takes the “large head” to a whole new scale