That’s beautiful! I didn’t know the name for it, but yes, the concept of piecing together different kinds of wood/leather/etc to make a picture has been noodling in my head. The word I was using was mosaic; though I know it isn’t exactly the same thing. That’s gorgeous. My compliments to the artist.

The other thing to look at is examples of marquetry - as best I can tell, intarsia means thicker wood, while marquetry refers to veneer.

wood build up would still be an option to create the “thicker wood”. I love glue

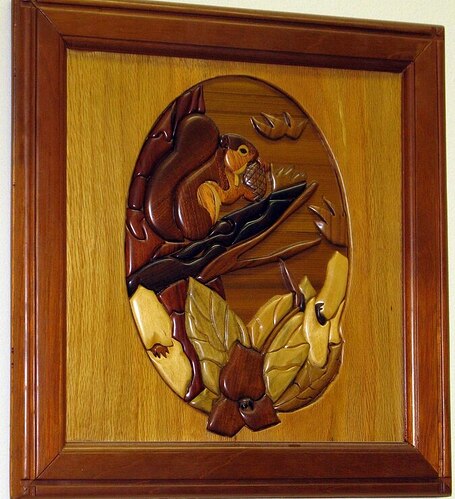

Beautiful examples! Just stumbled across this picture…

thats really well done. my compliments to the unknown creator.

When I decided to purchase my Glowforge, I had planned to use it to engrave images on wood, however I believe I can use for one of my other woodworking interests, intarsia. Intarsia is making a picture out of pieces of different colored woods, kind of like a puzzle.

This is an example of a picture that I did using many different types of woods. There are lots of patterns that are available on line, but www.intarsia.com is a great place to start. Most of the work that I do is not thick, so I think that the Glowforge could cut out the pieces. The hardest part in doing the intarsia for me, is making the different pieces of wood fit together. So with the accuracy of a laser printer, how can we loose. Do any of the others in the group make intarsia and do you think it is doable?I have read that I need to learn sketch up and Inscape to really get the benefits out of the printer which is a little confusing to me. I was under the impression that the software that is being developed would do all that I need if I have a pattern. Any thoughts on this would be greatly appreciated.

This is my first post, ever and I hope my picture comes out ok.

Thanks

This is really amazing work! The picture came out great!

If you already have a pattern, then you don’t need any other software.

If you want to design your own 3D models, then you probably want to learn a CAD package like Sketch Up, Fusion 360, something else.

If you want to modify 2D vector graphic files, then you probably want to learn something like Inkscape, Adobe Illustrator, or something else.

It really depends on what you want to do. You can still get a lot out of the Glowforge by just using patterns you already have or patterns that you draw. You don’t need to use anything else.

Necroing the thread here but i just stumbled across this…that is gorgeous work, David! Can’t wait to see what you can do with a laser.

This one of the things I bought the GF for. Some of the pieces for intarsia are thicker than the GF can cut, but I could cut 3 pieces and glue them together. The cool thing is the laser can engrave details and scores in the design as well. Intarsia with a laser seems a little like cheating the whole hand made woodworking thing. Much of intarsia though comes after you have cut the parts out. - Rich

I really love the intarsia work you did! It shows some real expertise in woodworking. - Rich

@chrgeup , you can use thin plywood to raise the pieces of intarsia for more dimension. The hardest part in making intarsia is accurate cuts that fit together tightly. I believe the GF can make these cuts easily.

Yes, the fit problem should be easily fixed by the GF. People will think us wizards with the scroll saw.  - Rich

- Rich