I could see an embroidery/sewing head being feasible.

so if we had an extruder and the laser head wouldn’t that be like having a pencil and eraser only in 3d?

I love the idea of an inkjet head. When I first learned about 3D printers, I thought it would be a good business model to offer architects 3D models of their designs complete with floor and wall coverings in color. Or for kids to have a doll house that looks just like their own house. Printing on plywood before cutting should work well for those kinds of projects.

I could see the potential for a longer focal range laser head. For those times you need to cut through something really thick…

Cut through to ~.5inches with the standard head, then switch to deep cut head for continued cutting.

but what if they go with a resin printer?

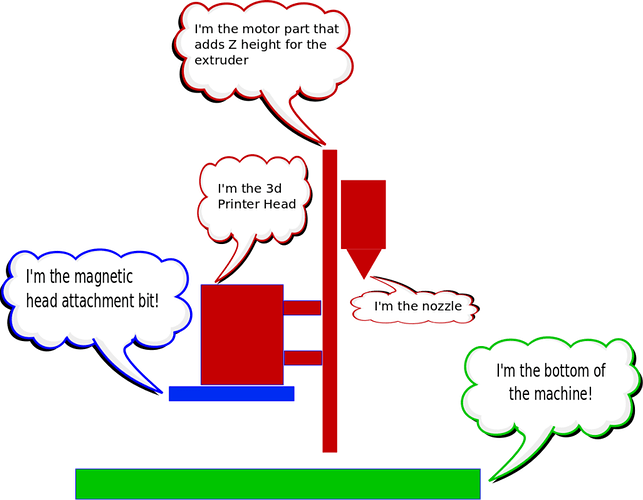

I think you need the nozzle to be the lowest part! Otherwise the Z axis will nock over anything you build.

I don’t really know much about those. Can you draw it? Be sure to include the thought bubbles.

So, you mean shorten the lowest bit of that tall rectangle to the height of the magnetic head attachment bit? Sounds reasonable to me.

3D printing would probably suck pretty bad unless they have some crazy ideas. No heated bed, small Z, nowhere for filament to enter the machine unless you have a passthrough, fan will vent all the hot air out.

If I had to vote for attachments this would probably go towards the end of the list.

I want the color adding head to be at the front of the list. ![]()

Maybe there’s a plug for bed accessories, too. Plug in your heated bed or some sort of chamber to contain CNC sawdust or whatever. Or, Proofgrade PLA. Doesn’t that have less need for a heated bed?

I’d say carve it, then print it would that application progression. Also, there is likely a printer that could print on a slab of wood or stone, but why have a whole new machine bed and controller when you could possibly just pop on a new head with ink formulated for your material.

Either way, you’re going to run into a power constraint somewhere. Some engineer type (we have 1 or 2 here) could probably figure out if the power source (30w running to head) could be capable of heating a bed to the required temp (specific heat capacity?) and still running some sort of tool on the head.

Thinking of my use case: flat bed printers can do the work on wood. I’d like to engrave prints for dimension. But you’ll need to refill what has been carved in most cases (or mine, at least). So my workflow would be to probably have the work printed on wood, load that print file into Photoshop and create my engrave areas. From there, I could use another layer that would isolate those engraved areas so I could lay color back in the engraved areas (minimizing how much ink I need to use). Color matching/profiles may be a bit of a concern but worth experimenting with.

30W isnt going to cut it for a hotend. They can peak at around 175W, and the bed will use around 120W. If theyre heating at the same time thats gonna be about 10x as much as that head connector can handle

I never jumped into the 3d printer market, though looked a few times. Our lasers will only be 40/45w concentrated into a very tiny area; 30w spread over a large area doesn’t go very far.

All of this being said and being a neophyte to 3d printing, aren’t their filaments that do not require a heated bed for stability?

yeah, PLA and a few others will work without a heated bed. Its much easier with though. The 30W limit is the deal breaker for the 3d printing function though. The hotend will never get hot enough to melt material effectively unless theyre using really thin filament. Even then I dont know if itd work

If the GF is anything like my CCL, that 30W figure has nothing to do with the power available to the GF. Its 30W is the output of milliamps at very high voltage, voltages that are completely unusable for anything like a standard 3D printer. I’m certain the GF contains two power supplies, or a very sophisticated single unit, providing the high voltage needed by the laser and the 3.3/5/12/24/48?? volts needed by the control board, stepper motors, cameras, etc.