I have noticed, when cutting multiple materials, that I get inconsistent depth of cut which results in:

- pieces not being cut free in sections when power is too low

- or excessive charring/burn through when power is too high.

I have also noticed the latter using ProofGrade stock which uses barcode presets.

The problem is best exemplified when cutting foam-board because this material is very consistent in density and most indicative of power fluctuation. The following pictures show curves generated by NURBS CAD software that was printed to PDF and uploaded to the Glowforge app. The PDF files are tiny taking up a few KB and appear to be passing clean curve data rather than interpolating curves as short straight lines.

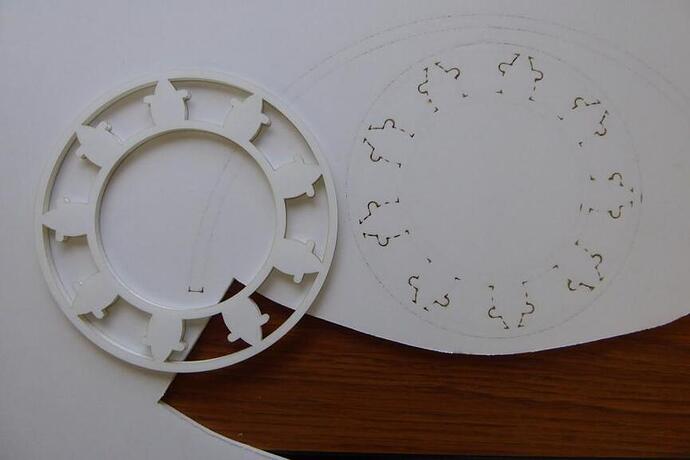

This pictures shows a successful cut out of piece, on left, where power was sufficient to cut all the way through. The board underneath shows the same piece from the underside where power was not sufficient to release the piece.

FYI, This piece is a simplified representation of a 9 cylinder radial engine. All cuts use the same settings and are split across three layers.

The 1st layer is interior circle which is cut as one continuous curve starting & ending just south of east and appears as a short dash on the underside cut visible on the right. Note that start/end cut within 1/4" start/finish cuts all the way through but the rest of the circle does not. This is problem #1 - where start/end of curve cuts deeper then rest of continuous curve.

The next layer cuts the voids between cylinders with Glowforge cutting again as one continuous path per void. This is where the acceleration/deceleration problem become most apparent. Same cut settings but you can clearly see that corners and tight radius arcs are cut all the way through (burning back paper in corners/tight arcs) where as lesser angle arcs do not cut through.

Finally the exterior circle is cut on 3rd layer, again using same preset, and almost makes it through. Note that this exterior circle cuts deeper than the 1st tighter interior circle using same preset.

I ran many test cuts and the power/speed setting produced greatly varying results using tiny variations in power/speed settings.

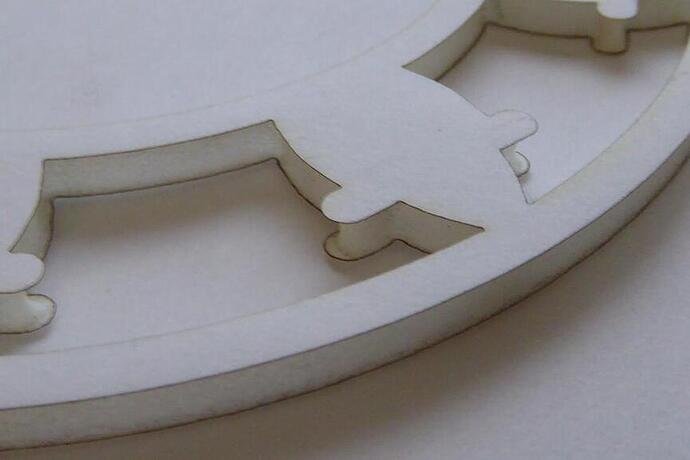

This picture shows the best results I got which shows heavy foam melt on tight radius arcs (almost picture center) and little to no foam melt on larger arcs, interior/exterior circles using the same settings.

Does the Glowforge app adjust power setting when accelerating/decelerating the cutting head?

I understand that foam-board is not a proof grade material but the same thing happens, to a lesser extent, on PG medium board, so the problem is the same.

If so then acceleration/deceleration ratios should be adjusted to accurately compensate.