hi.

what’s wrong??

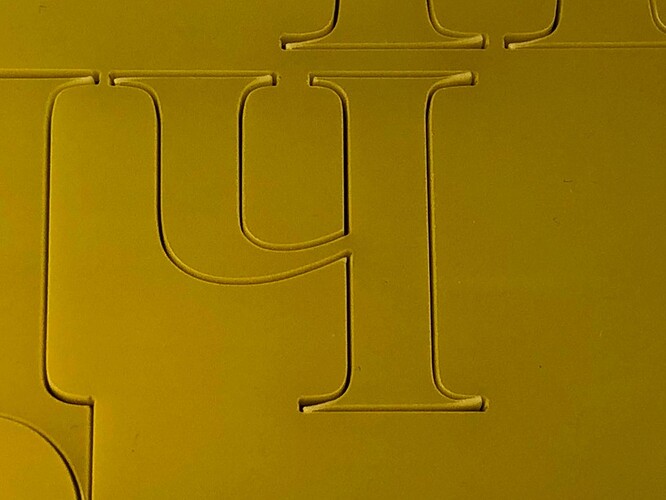

I am guessing the thin parts of the serifs are too thin and are heating and warping. You can try breaking up the cuts so that each top cap is cut separately to give the acrylic time to cool between cuts.

Agree, the points of the fonts are relatively small so the laser stays in the same relative place too long causing it to heat up. Are you using the proofgrade settings?

I’m so sorry your print didn’t turn out as expected.

Since this problem is being seen on materials that were purchased from another company, we can’t offer support for prints that don’t come out as expected. I’m going to move it to Beyond the Manual so other folks here can help. Should this happen with a print on Proofgrade materials, please open a new ticket in Problems and Support and we’ll help you right away!

I addition to what was said above about thin areas, you may also want to make sure the material is completely flat on the dray. Some of that looks like the material may have fallen to the tray during the cut. That would give the tapering, too. My biggest difficulty with acrylic, though, has been the high heat on cuts where it corners.