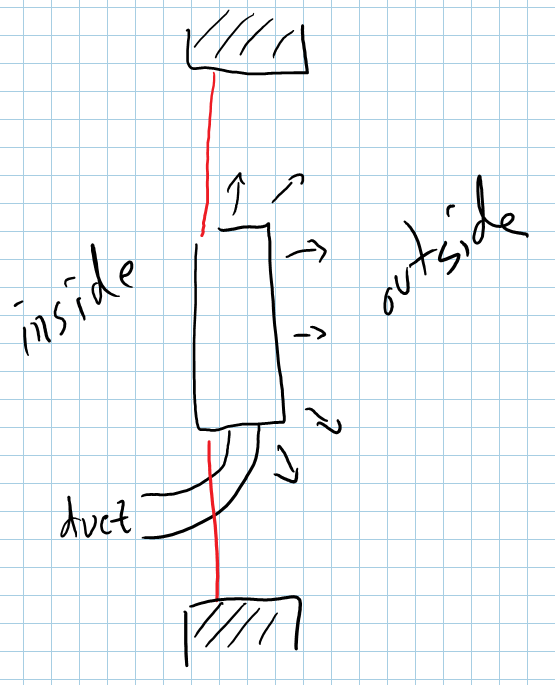

There has been discussion of venting filtered air out the window, so as to minimize objectionable fumes reaching nearby neighbors. Now that we understand that the filter is coupled to the Forge via a duct, couldn’t the filter be mounted in a window and connected to the Forge by a longer duct? This assumes the exhaust from the filter comes out one side…

“which exhausts through many openings into the surrounding room”

Probably not on one side.

Then perhaps if exhaust comes from all but one side, a partition could be built to include that one side, with all the other sides outside the partition and venting to the outdoors?

This shouldn’t be a problem if they use a diffuser at the filter to disrupt the inward airflow and slow it down by spinning it into vortexes and thus spreading it out. The drawback of diffusers is that by sitting in the way of the airflow, they tend to collect larger debris.

You still have to account for pushing the airflow all the way through the duct tubing. It may be empty space and everything may be tightly sealed, but all that air in the ducting provides resistance that the single lone GF fan shouldn’t push alone by itself.

My understanding is that the filter has its own fans, so the task of moving air between the Forge and the filter is shared by the two devices. Regardless, if the longer duct proved to be too much resistance, an inline booster could be added. I’m just suggesting that if someone wants to go to the trouble of venting cleaner exhaust, it should be do-able with this arrangement. The earlier idea of building a shroud around the filter and venting the effluent out a window would be more difficult to accomplish.

Another point to consider is that the two 90 degree bends in the coupler translate to many feet-equivalent of straight duct. If the connection between the Forge and the window mounted filter could be accomplished by a relatively straight run of duct, it might actually cause less resistance!

You may still need the shroud if the filter doesn’t have a top cover. Which would be reasonable since it is meant to sit under the glowforge, so a top cover would be pointless.

If that is the case, I would imagine that adding a flat panel to cover the open side of the filter should be pretty easy to do.

I totally agree, 90-degree turns are the Devil’s work and pretty much the equivalent of air hitting the side of a building/wall. The fact that it’s expected to do a complete 180-degree turn to go back into the filter sitting underneath is going to add noise, I think, as well as everything else. An as-straight-as-possible route is definitely the way to go.

I guess I wasn’t clear from your pen drawing if the center-window duct egress was intended to be fan-assisted or not. I assumed not, my bad.

By the back and forth on this thread it is clear we still have no where near enough info to do anything more than speculate as to the design of the filter or the GF filter interface. Also keep in mind there is likely some sort of common control. If I remember correctly the fans on the filter and cutter are controlled through the cloud,. That might mean an electrical control between the units. Until we touch a filter or see a demo everything is still guesswork.

Very good point. I forgot about the electrical connection!

Correct.

No, because…

also…

I’m not going to tell you it’s impossible, just that it’s nontrivial. Very nontrivial.

So probably some sort of custom electrical interconnect that would be hard to extend to a window?

I am pretty sure it was said that the air leaves the filter out of many openings in the bottom. Mounting the whole thing in a window like @fan-of-glowforge mentioned is an intriguing idea, but you would need a pretty big window to mount it into. The filter dimensions are larger than an entire average 1970s era basement window, for example (based on my examination of said windows in my basement :-))

My thought is that it might be easier to place the Glowforge/filter combo onto a custom-built vacuum table that would suck the majority of the filtered air down and then out of the room through a pipe. Even if it got only most of it, that would still go a long way towards ensuring the canaries live another day when you want to raster a detailed photograph onto a 12x20 sheet of something that releases Formaldehyde.

Oh yes, I now remember seeing how big the Forge is. So my drawing is way out of scale! That window would have to be sliding-glass-door sized! Thanks for putting things in perspective. BTW, I like the vacuum table idea…

Agreed. I think a vacuum box will be the first thing my GF makes. At least the first useful thing…

Hello, I just got my GF plus and I am using it on a daily basis to create placards. The constant cutting of acrylic is a rather pain full smell to live with. Has anyone purchased the air filter and used it in an office environment? If so have you used it with acrylic? Does it get rid of the smell?

Acrylic does stink! I don’t notice any strong odor until I open the lid of the Glowforge as there is always a bit of smoke trapped under the material. I changed the hose that came with the Glowforge for a sturdier one and had less odor. I also have securely taped the exhaust joints and made sure the area around the window vent is sealed securely.

The airfilter has received mixed reviews in that the filters are expensive and need to be replaced. If you cut/engrave draftboard or plywood the filters fill up quickly and that is costly. You might read some of the comments here in the forum about using an inline fan and how it makes the operation of the Glowforge quieter and some say less stinky. Others discuss using a room air purifier.

Before buying the filter, I suggest trying a few other things and see if you can diminish the smell.

If you’re OK with replacing the $250 cartridge every few weeks, it might help. Check the posted filter estimated longevity specs to see what you might expect from it. One person got 10hrs or so.

Otherwise, as above, I suggest you check your vent arrangement. Coming up on 4 years here and never had any issue with smell, despite my vent being about 30’…

WOW, o-o I had no idea that the filters were 250 a piece. or that they were so frequent in changes. Dklgood I really appreciate the response with this information I will look into a better ventilating option.

Filter longevity is really dependent on what materials you cut. Draftboard /MDF being the worst and acrylic and leather being almost the best. I’ve used mine for several months on Baltic birch ply before needing a change. Venting outside is the least expensive and a good in-line can at the end of the exhaust run can do wonders but for acrylic as you state you should get quite some time out each filter cartridge.