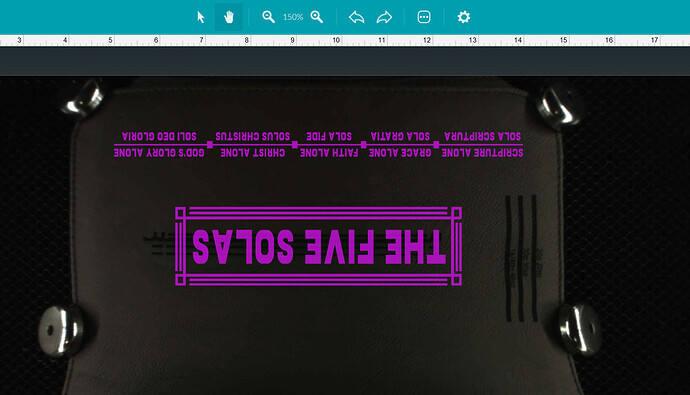

Hello, I am laser engraving on bible covers which are 6mm thick. I have entered this into the material thickness section and I have measured with a ruler the placement of the cover in the Glowforge so it is exactly centered. I have also measured on screen the distance from the edges of my design to the edges of the bible cover, so it appears perfectly center, and yet you can see the burn marks on the cover where the design actually burns, is WAY off.

have attempted to increase the thickness just to mess around and it doesn’t seem to move it anywhere, or change the location. Does anybody know why the engraving is SO far off? I would appreciate some help if anybody has any ideas!

For a repeated procedure like that, you can put a bounding box around your design the exact size of the Bible in a different color so it shows as a separate operation in the GFUI, register a piece of cardboard on the bed with tape or magnets and cut the box out ignoring the engrave, put the Bible in the hole and run the engrave.

After you remove the cutout and close the lid, the new image of the bed will show the design displaced. Ignore that. If the cardboard jig hasn’t moved, the design will register perfectly.

Thank you for your reply. Is this bonding box done in GUI? it in the SVG file in AI?

You would draw the outline of the Bible dimension and position it perfectly in your design software and save the file with it. What software are you using for designing the text?

Edit; Oh, sorry… AI.

I’m so sorry your prints didn’t turn out the way you expected. One thing I’d like to confirm is the thickness of the material. For the most precise alignment, it’s important that the material height entered in the app is accurate to the total height of the material above the crumb tray. If there is variance in the height of the material, that may result in inaccurate alignment.

Since this problem is being seen on materials that were purchased from another company, we can’t offer support for prints that don’t come out as expected. I’m going to move it to Beyond the Manual so other folks here can help. Should this happen with a print on Proofgrade materials, please open a new ticket in Problems and Support and we’ll help you right away!

One other thing to consider (after you’ve done the trick with the box to register exactly where the image is going to go) is that the magnets on the edges aren’t doing a good job holding things down, and may even be distorting the shape of your cover. Magnets anywhere that the image isn’t, or maybe a hold-down made of wood going across (and secured by magnets or pins at the ends).