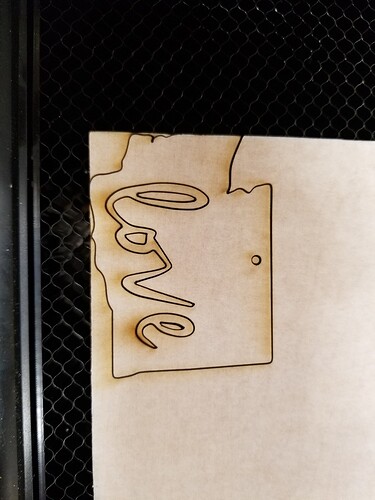

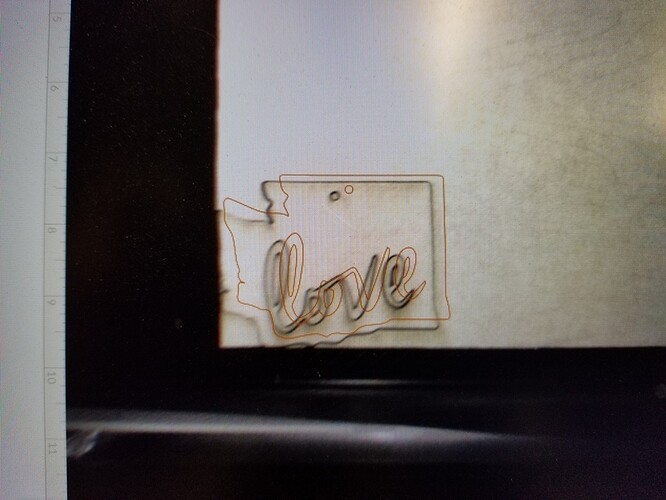

So I finally recieved my glowforge and was super excited to get it up and running and start cutting gout all the projects I’ve had backing up over the 2 plus years waiting for this thing. Go. Through all the setup, place my material, upload my image, all looks awesome on screen. Hit that print button and watch the magic happen. Until… I notice the laser is cutting too far to the left cutting off part of the image. I refresh the bed image on my laptop and the two don’t line up at all. I thought this was supposed to be better than using a red dot to align your work? I’ve never had a red dot fail me like this. So now I can’t do quite a few of the things I planned because I need accurate alignment of the laser over the work. What give people? This is totally and completely unacceptable.

I assume you’re already aware of all the discussion on the topic as well as the workarounds and just would like to also add your voice to the others of disappointment in using the camera for alignment, correct?

What material did you use? If the thickness isn’t correct file placement will be off.

That last image looks like a post op pic, the software places the file initially, the camera image post cut is displaced. Regardless of the image offset seen post op, if you were to run the file again without moving the material, it will cut in exactly the same place, even though the image looks displaced.

You can currently expect visual placement to be off by up to .25". This will, one day, be corrected. Until then you want to get to know your machine (placement varies slightly machine-to-machine) so you can place objects where you want them. If you look through these forums you’ll find things that have worked for others.

Yes after more than two years GF doesn’t home or align as well as a cheap laser cutter with limit switches and a red dot laser.

Suggest you buy one of those then.

That was my original plan. Rip out the electronics and put in my own and program it myself. Then I saw the GF advert and thought I would treat myself to a deluxe machine with everything done for me and use if for my business.

Now I find the hardware is good but the software is rubbish and doesn’t look like it will ever do what I want but in the meantime I am have retired and now have time on my hands. So I will go back to plan A but using the GF hardware instead of the Chinese machine. Probably won’t need to replace the electronics as it looks sound apart from not having limit switches and an Ethernet port. I can probably add limit switches on the SPI bus if there are no spare inputs. But might replace it with my own to get Ethernet and use servos instead of steppers.

That surprises me, given the price differential between the two, and the fact that you could have a Chinese laser much sooner so you could start implementing your modifications right away, and wouldn’t have to kill time for another several months.

But to each his own.

And a bigger more powerful one. Before I pulled the trigger I was going to do a 130W Chinese laser with a 3’x4’ bed (adjustable Z axis). You can run Whisperer with the stock controllers or swap out a Cohesion or Smoothieboard and run LaserWeb for the software. The bigger Chinese ones also usually come with RDWorks which is far better than some of the other software options with the small units - so you could even get away with an unmodded machine. The Sarbar videos on Youtube are a good source of RDWorks intel too.

Did you do a baseline cut on proofgrade?

My buddy who has years of laser cutting experience from the creative side (he doesn’t own a machine and always has used a vendor) and I were using a bunch of scrap laser woods and other non proofgrade materials this weekend and found that visual alignment was usually off until we digitally calipered the material and entered that number for material width. When we did that and refreshed the bed image we found the camera alignment to be spot on. We were amazed at how easy it was to utilize all the left over spots from previous laser cut jobs that were available on his exotic wood that otherwise would have been useless for laser.

Not to highjack a thread but for all the belly aching about the GF software I was really apprehensive (until 15 min after unboxing)- my buddy this weekend kept commenting to me how easy and intuitive he found the software and interface to be. We were tweeking little settings on speed and power to get different results and felt like grown up kids playing with an expensive toy. Haters gonna hate but boy these are two really happy middle aged kids. My buddy will be using my referral code this Christmas.

There are some quirks in the GF web interface, certainly, but once you learn the workarounds, it’s actually pretty good - I’ve been cranking out dozens of objects for the holidays, and once I figured out how a smooth design and workflow, things are working nicely, and the output is fantastic. And hopefully over time they’ll eliminate the need for those workarounds. But to put it in perspective, ALL laser cutters have their quirks. The difference (I hope) is that GlowForge pushes out updates frequently.

That’s a bummer that it cut off the edge of the Olympic Peninsula.

I grabbed a copy of the ruler there in your picture and compared the top border of the state with the cut. Right at 1/4". It should only get better from here as they make their improvements to the camera alignment.

Ha, I am not killing time. I am in Tenerife for a month at the moment, back for Christmas with family and friends for three weeks and then on to New Zealand for a month. About a week before we return I am scheduled to get my golden email. I mentioned that to my wife the other day when we were planning things in Feb and she laughed so much she nearly fell off her chair.

At the moment I am designing a new 3D printer, which I work on when away for winter. I have a big list of projects to do when I get home. A friends wants me to design a control system for soap packaging machine.

So I don’t expect to ever have time to kill but I do get to work on whatever I want.

The GF is a much nicer base to hack than a Chinese machine and I don’t have room for anything bigger, so can’t take advantage of the higher wattage machines. I have been tempted many times though. I will decide when the next delay is announced.

Enjoy your “retirement”

The first company I worked for as programmer, way back in '80, was a DoD contractor. I was working on ancient machines that only existed in a few places at the time. All of our programming was via punched card “edit decks”. These were handed off to Configuration Control and we’d get back new print-outs of the code (all assembly language) and a magnetic tape reel with the binaries on it.

The head of Configuration Control was a guy in his '60s. He worked about 1/2 time and had come back to it from retirement. He had retired, had a heart attack, quadruple bypass surgery.

He said that being back at work he was golfing more than he had during retirement. Work gave him something to keep him busy and focused.

I’ve still got a decade or so before I “retire”. Might go for another start up sometime soon

Thanks @johnse, that’s right.

We’re still improving our layout and alignment, so your print may appear offset from where you put it by up to a quarter inch. For the most accurate alignment results:

- Use Proofgrade materials

- Enter the thickness of the material if it’s not Proofgrade

- Use material that is not warped or tilted

- Place your design near the center of the bed

- Reboot the machine if you see the alignment drifting