I don’t have that…I have a basic. But, to your other questions…yes, I’ve been able to line stuff up successfully…and when dealing with a more difficult thing, I’ve also made templates. I’m sure we’re different like that, though. I don’t mind doing it. In fact, that’s part of the learning curve and I’m loving it all.

Except approachability for the huge non-technical user base, it definitely gains there. Don’t underestimate that, there aren’t enough of us math-oriented types to support a company like this. I don’t need to tell you how much you can do with this machine (I mean you’re groovestranger, you know what you’re doing), the lack of standardized movement/min amounts hasn’t stopped us from making amazing things; I’d even say it didn’t slow us down.

But do you know how much more powerful it is than 100? Do we know how many watts 100 is?

Ah, I see what you’re saying. While the engineer in me might care, the hacker/crafter doesn’t. I’m too busy having fun, and the little details just don’t seem to matter for how I use this tool. My challenges tend to be in the realm of design, since the mundane details I’ve worked out and written in a little notebook.

Should I care? My notebook of settings for all of my lasers are different. Doesn’t stop me from being productive and if the GF said it was 42W (I have a Pro) and the Redsail said it was 50W and the K40 said it was 40W I wouldn’t know anything because I know the K40 is lying (I have a calibrated laser power probe). Haven’t bothered checking the Redsail and haven’t figured out how to get the probe in a steady beam in the GF for the 30 seconds it needs to read.

My life is not noticeably more difficult.

@iancandace Instead of randomly trying out settings I modified a suggestion by @evansd2 and set this up as just a piece od any new material …

It takes work to set up the first time but I leave it in the GFUI and use it as needed. You set all the cutting speeds to the numbers noted and the engrave speed to twice those numbers (all full power) the last cut cuts across the engraves so you see how deep they are. I sand that face down a bit till I see clean wood and you can see how deep each cut is. or you can look at the bottom and see which cuts made it through.

If you watch carefully you can see if the smoke catches fire and if it starts catching fire at 400 or so you might want it wet while cutting or use some other species.This is Zebra Wood…

Download the SVG above and it will provide all the settings you need @jamesdhatch was just pointing out that the practical application of your experience and notes are what counts. It is interesting that Glowforge does not hype the numbers as much or that you don’t want to run other lasers at full power but if I had another machine I would have to run the same tests and note which machine it was.

Folk here are trying to help and insulting them does not make it better for anyone and can eventually get you tossed from the forum.

Frustration comes when you realize that the 40 W laser is not really in any way the 100 W laser you need to do a Beautiful engrave on Stainless.

The very first thing I did on my Glowforge was to Engrave on my Mac Book at Full Power with a pass over of 10 times.

It was than I Realized the limits and quality of the laser.

Next I Layered four pieces of acrylic with a piece of paper between each , and again I found out the limits of the laser.

Full Power was nothing more than the laser being just a bit wider spread, better for Cutting through thick acrylics

Yes you can do stainless, but its not anything your going to want to show your friends and they are not going to be wowed by the engrave as no one was wowed by my Amazing Engrave on my mac, its just not true pro quality .

With that said the Joy comes from being able to use the Machine to create those things that a 40 W does extremely well, but Stainless is not one of them.

Even if you do manage to get something good it wont be consistent and that means huge waste of material.

We all wish are laser could be converted to 100 W and than we would be Etching away at are silverware especially my guns, its just not going to happen nor worth the results when a 100 W laser was made for it.

We have 40 W, Once you accept that is the challenge , the only real frustration is Lining things up for repeated cuts and knowing that the laser is not 100% consistent and so you have to deal with that .

The glow forge has been amazing for are business. I fired the razor blade, the ruler, the circuit cutter the brother scanner and forbid scissors anywhere in the office.

The glow forge community has been amazing, and have shared with me there bread and wine for which i have been very great-full. Saving me much time and energy but required work none the less

Now take a deep breath, forgive Glowforge for not being the 100 W we all want some day and focus on Creating , an concept work, for which it is perfect for.

My only frustration is when even the Proofgrade stuff, which is supposed to work out of the box, doesn’t. I’m fine with testing my own materials, I expect it. But I also expect the PG stuff to work as advertised, and yet I still have instances where it just doesn’t cut all the way through. The point of buying this,m and using PG was to skip all the test cuts and trying different settings… And yet, still today, I’ll get PG that doesn’t cut all the way through as expected. When it happens, everyone is quick to jump “clean it”, “make sure it’s clean”, etc… I have no piece of machinery that is as clean as my GF because I want it clean and working, but I still get incomplete cuts. All the time. To me, that is the frustration I have with this thing.

Hi, I was reading thru this last night, but woke up this morning with another response I’d not seen (though I didn’t get through all the posts):

When you say you have material that you know is “stainless steel”, do you know what alloy/grade it is? Is is austenitic or not? Hot rolled or cold rolled? (There are scores, if not hundreds of alloys, some only vary slightly & provide similar results, but other grades or processing will). Are you buying new, or scrap, or using finished tools or cookware or something?

It’s like your saying you have a piece of wood. Well, what species? Maple will give you very different results than IPE for the same machine settings (any machine–jig saw, lathe, router, and laser), and so it’s like expecting the same result between different alloys of “stainless”.

Do you blame your CNC router if you get different results on a piece when you set it for maple and run IPE (as an example)?

So don’t blame the machine–if you find settings that work on one piece of stainless (call it test piece), and you pull another piece from a scrap bin, and no idea if it’s the same alloy of SST and get different results from your test piece, well, it’s most likely different alloy or processing/finish. But if you’re running a second piece known to be same as the “test”, that would be more likely machine related.

But given that–even with PG materials, results can vary if the material is not perfectly flat (mostly for cutting, less noticeable with etching) & the lenses are not clean (40 hours was only a guideline, I always clean more frequently).

So don’t give up on it–understand what Stainless you are working with and your sourcing of it for consistency.

Insulting can be in many forms. One of the forms is interjecting into a conversation just to add “their two cents” when it is not relevant, nor Adding anything positive to the conversation. For example, if I have a complaint about something and so do you, then comment. If no one else does, then the forum stays short, I see that I am “on an island” and the thread disappears after a month of no activity. But, if you do comment, and it builds up, maybe they will consider the thoughts of those that commented.

A portion of commenters in this forum tend to comment when they aren’t even involved. Almost as if they like to hear themself talk.

Yours, was very acceptable, and actually appreciated.

My point in all of this is, despite frustration and venting, is that it is very odd to me that there is no correlation between their units of measurement and being able to plug units in based off of consumer products made for laser application.

Case and point, a buddy wanted me to engrave a logo on to his lighter that he keeps while camping. It’s stainless. It’s small. The Cermark gives you specific values of power based on wattage and speed for stainless. I don’t have a lot of stainless around to “practice” on and don’t believe I should always ha e to practice when the product has specified what already works. It came out pretty lame. And from searching the forum for assistance before doing it I found one person that went through a lot of their material before getting acceptable results. You don’t always have multiples to practice on. The light wasn’t a failure, but I still think it looked like crap for what the product has done for others on similar items.

Oh, don’t even get me started on that subject.

It’s really great when you clean everything and do a “longer” job and it quits cutting through PG 3/4 of the way through.

I like you, keep the lenses clean constantly. I also have a crap ton of magnets in place to keep the material completely flat on the tray. PG tends to warp…a lot.

Came here to say this. With any other laser you will start with much less, or maybe nothing. Everything needs to be tested.

Take for example MDF. Glue content in MDF from Lowe’s is completely different from that of the MDF from Home Depot. So settings between the two are wildly different. Sometimes they’re different between batches at the same store.

The only thing I’ve found I can really count on having consistent settings is acrylic. The nature of these machines is that you will have to do some research, but the end result is well worth it.

(I agree the speed units are terrible)

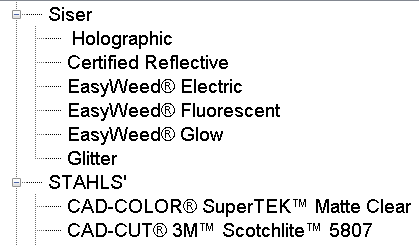

to be fair, it depends a bit on the laser and the SW you use. but also, consider the cost associated. the Universal comes with the Universal Control Panel. Inside the UCP are starter settings for LOTS of materials.

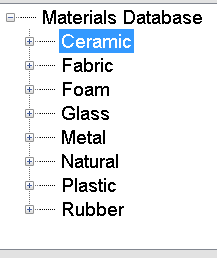

Base categories:

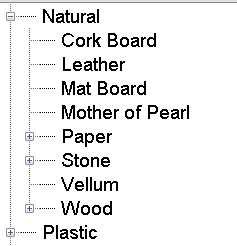

each of those opens up to subcategories:

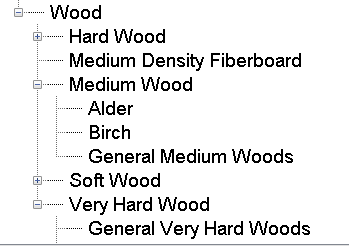

and those subcategories open up to even more

under fabrics, getting very specific:

that said, the universal cost my company $35k, not $2.5k to $6k. and their system has been in place for years and they’ve been developing that material database for a very long time. who knows where GF might be in 5-10 years.

The other thing that’s important besides cleaning is making sure your material is FLAT. I see people complaining all the time about not getting cut-through, and the photos they post show the material just lying on the bed of the GF with nothing holding it down. None of the stuff we cut in the GF is going to be absolutely flat – NONE of it. There’s always a tiny bit of warp, and that’s all it takes to keep the precise settings from not working. Magnets and hold-down pins are your friends!

I’ve had my GF for 8 months now. I can only remember ONE instance of it not cutting through PG material that wasn’t explained by dirty lenses or non-flat materials. The problem never repeated itself, and all I can figure is that I got a sub-standard piece of PG. Considering how much of the stuff I’ve used, though, that’s a pretty good record.

I’m well aware of it needing to be flat… I stack my material to prevent warping, or as much as possible. I and I always use very strong magnets to flatten out may material, and is a lot of cases, it doesn’t matter. Still doesn’t cut all the way through, consistently.

Then you should open a support ticket and have them check it out!

Confused. Your MacBook Pro isn’t stainless - it’s anodized aluminum. And it shouldn’t take 10 passes to run an engrave on it.

The Glowforge is a 40/45w CO2 laser. It’s capabilities are going to be that of a 40/45w CO2 laser. The machine is what you make of it and the results are only a result of what you put into it.

I don’t necessarily disagree with the obfuscation of real world inches per minute but it’s also not that big of a deal to make the conversion. It takes seconds.

As far as power, good luck with any standard there. You might get some mA inputs on some machines, some are % inputs, etc. and then you still don’t know what the real world power actually is unless you’re using testing equipment like @jamesdhatch mentions.

I have certainly had many issues as I have learned my way from knowing nothing about the laser cutting. I too purchased the Glowforge because they promised that I could operate it from knowing nothing. I have too many friends that bought lasers, 3d printers and CNCs that never got the first piece out of them, I paid 7K for a CNC that never worked properly and had a 3"x 6" operational area and was several generations more primitive than what is available now. Even so the natural limitations of the concept I had not considered such as the minimum diameter of a cut was also its maximum width and the material severely limits the highest speed no matter how strong the machine.

The laser too is not magic. I had many ideas before mine arrived that are not possible due to the nature of the machine and the universe that only trying them out got across to me. Another friend insisted on cutting metal (he has worked mainly in iron) and so got a plasma cutter, however has found his universe very limited as well most painfully not being able to engrave as we can.

The design I provided to you above pretty much covers all the bases for settings as you can run one a full power and a second at half power etc and have a permanent record of what works and what doesn’t. I have a box full of them just for the different woods. you can also use it on a bit of stainless with several different formulas that folk have noted and see what formula works best for you.

I got a stack of anodized aluminum business cards and was not really happy with the results, Since then I do a carving on a bit of scrap and contact information on the other side and those have been very popular as folks keep them handy just because they like the carving and show it to their friends something you do not get with any printed business card.

I have not yet attempted to work on anything too good to lose for the very reason that it would be a very bad thing to lose it, Even the more valuable hardwoods have taken several tries to get right losing much in the process. The design above puts you in the ballpark but cannot account for differences in the grain of the wood that may be more laser resistant in some places than others and almost nothing I have made did not take far more hand finishing that the design and cutting did.

FWIW, looking through the recommended settings for Cermark, I see this at the top:

These settings are designed to help guide the user to the optimum

parameters as quickly as possible. Please note that there will be variations in substrate finish

and between different brands of laser. It may still be necessary to perform further refinement of

settings to achieve the desired mark.

Guide. Quickly. Variation. Different brands. Refinement.

I can commiserate with translating the speed settings over. It takes a few seconds to do.

But the reality is that you’re almost assuredly going to have to test anyways. I’d say the good thing about using a product like cermark is that you can test right on the product itself, no? Either, A. Have delivered too much power and vaporized the product leaving no permanent mark, B. Nailed the power and speed and have a good, permanent mark, or C. not going to have applied enough power and leaving no permanent mark.

I can understand gripes and concerns relating to alignment, some of the stuck on focusing/scanning issues, etc. but I can’t really get behind something like having to test on materials… perhaps that added nothing to the convo.

The flipside to the comment above about “if I have a complaint about something and so do you, then comment. If no one else does, then the forum stays short,” I’d like to imagine they’d like to hear various viewpoints on a topic at hand. What may be a dislike for you, may not be an issue or even advantageous on my end. Point being, why would they want to hear from people with only a singular viewpoint?