The one on the left is easier to make out the numbers

I think if I use this one the numbers should be engraved to make them darker. But it just seems awfully “busy” to me. I think I still like the original better… I don’t know.

The more I look at it, the less I like it…

i like the simple dial on the right. if people need 3s to tell time, they do not deserve to know from that clock.

Skip the numbers. It looks like part of the gearing so I like it. You could do 12/3/6/9 if you must have numbers or make them in binary or hexadecimal

I had actually considered binary, but I kind of like the hex idea too!

Here is another variation I am considering. It is kind of a cross between the two…

(I moved the connection points in a little, so this one requires different mounting pieces.)

Here are the other two again for easier comparison. (I think I fixed the perspective of each also.)

I am really going for the gear look, but I feel the other one was to big.

My wife liked having the numbers on there too, but I think I prefer it without…

- The original (clean and round)

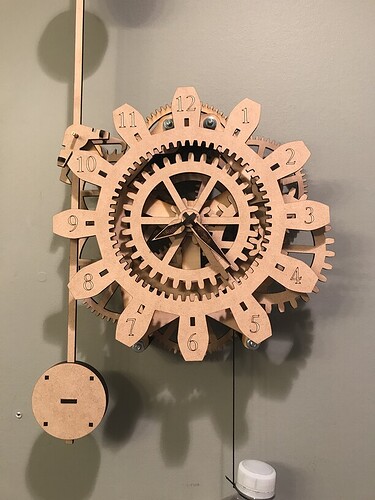

- The new (large gear with numbers)

- The improvised (narrow gear without numbers)

I like the binary version, but for most people the numbers are worthless anyway…

And the hexadecimal would be mostly the same as normal except 10, 11, 12 would be A, B, C.

I have the new clock fully assembled and on the wall, but it is still not running.

I am trying to track down a friction point (or many) that is robbing the gear chain of power to push the pendulum.

I have not applied Dry Moly to the gears yet, so that might be a next step. I also need to cut a new escapement out of acrylic. I do believe those work much better than wood.

I was just hoping this clock would “work” right off the bat, but that was really naive of me. I still have high hopes for this clock, but it is going to be a lot of work still. Of that I am sure.

Edit: Well, I recut the escapement in acrylic (nothing else), and the gear chain will push the pendulum for a short time. So I was correct about one of the friction points!

I really do need to see if I can come up with enough acrylic to make a whole clock out of…

I have a boatload of 3x2ft Optix green glass from Home Depot in 4 or 5mm you can have but it’s extruded so you’d need to mask and then paint your numbers. I could break it down to fit into a large flat priority mail box for cheaper shipping - I think those are 18"x something.

Wow, I really appreciate the offer, but I have a Home Depot just minutes away. I will see if I can find it there.

I might need to adjust my design too, if I use thicker material.

I think the green glass would make for a cool looking clock too.

I have a lot of 18x24 that works fine in a pro, but not so good in basic.

As your gear on the number thing is bigger than the gear below I think you could make that inside gear smaller and since you have the frame poking through anyway I think if the numbers covered that rectangle it would improve the look,

I am contemplating additional ways to make the frame look more like additional gears.

My concern with making the diameter of the inner circle smaller was interfering with function of the clock or obscuring the real gears…

I was thinking the inner gear of the outer piece narrower to almost match the inner piece. The other way would give you less inner piece and we don’t want that ![]()

Maybe I read that wrong… Lots to be said for inner peace ![]()

Are you saying I often add metaphors in speaking about other things having nothing to do with the original point? ![]()

I was simply referring to spelling piece vs peace…

As in “If you are just sitting cross-legged with your eyes closed an humming searching for your inner piece, shouldn’t you just be looking around where you had it last”?

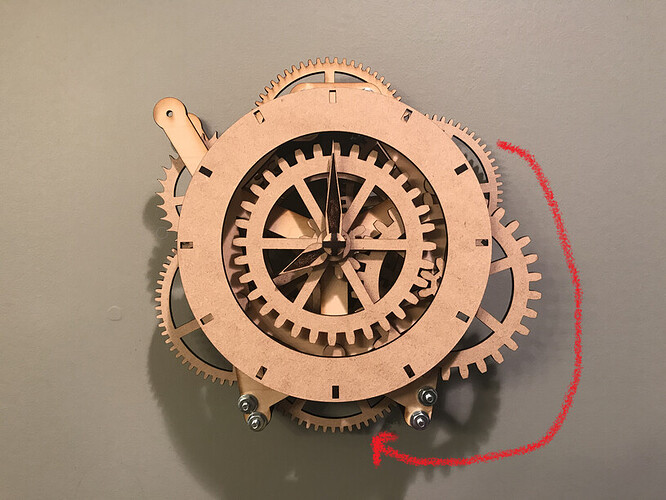

In an attempt to troubleshoot the issue with the gear-chain, I am going to temporarily move the weight.

This will greatly increase the torque in the chain, but it will also greatly decrease run time.

I believe the issue is with the minute-axle. This change should move the power to the other side of the issue. I am hoping this will allow the clock to run long enough for me to be able to find some “witness marks” to help me locate the actual issue.

Otherwise, this could help break-in the clock and help it function normally. (These are all assumptions at this point. I will hopefully learn more by this process.)

Edit: This is the result:

I reduced the weight also. The power transferring to the pendulum is MUCH higher. It is making a much louder ‘Tick… Tock…’ now. So I will let it run and see what I can learn.

I looks like the clock ran for about 5 and a half hours with the weight wrapped around the lower axel. (Which is longer than I expected, but I also realized the axle is much smaller diameter than the original drum.)

Unfortunately, with this temporary setup I have to disassemble the clock to rewind it…