Can I make a groove or slot for a box with a sliding lid?

I would normally cut something like that on my table saw. I imagine my file would have a vector box with a greyscale bitmap for the engraved groove.

Can I make a groove or slot for a box with a sliding lid?

I would normally cut something like that on my table saw. I imagine my file would have a vector box with a greyscale bitmap for the engraved groove.

From what I understand, this should be doable. May take some testing, but I don’t see why not.

That would be awesome. I am not opposed to cutting them on the saw. But it be so nice to be able to save the file and “print” a new one every time I needed.

Exactly. Oh the possibilities that the GF offers…

This is one of the things I am curious about as well. I see no reason that it couldn’t cut a groove, although getting the bottom of the groove squared to match with a square-edged sliding bit might be an issue because of the hourglass-kerf shape. I would also be curious how much time it would to cut a groove and how much laser-life-time it would cost vs. doing the same thing with a router, a shaper, or a saw. I am thinking that I may want to mark my slot placement with the laser, but cut it out using a router.

I also don’t know if it will be easy/possible to do a half-cut/deep-engrave, and then follow back through by hand with a chisel, but that might be a way to go for folks who don’t have the power tools or just want to use traditional methods alongside modern ones.

If your doing repeated cuts you might be able to save quite a lot of time by instead making a template with the forge. This way you can still have the accuracy and save laser life. All it would require then is setting your bit depth. I plan on making a lot of templates for my woodworking with the glowforge.

The one concern I would have about this is that if you are working on solid wood, there may be an issue getting the slot to stay exactly the same depth for its entire length due to differences in hardness as the grain changes throughout the cut. For this reason, as well as the whole laser life thing that @jbv mentioned, I would want to lean towards using more traditional methods for slots, especially in non-homogeneous materials.

It’s going to be hard I know, but we will all need to try to remember that just because we have a laser cutter/engraver (he he he!) doesn’t mean it has to (or even should) be used for every aspect of every awesome thing we plan to make with it.

“If all you have is a hammer, everything looks like a nail”

I was getting carried away. The thought of making everything from the comfort of my office, rather than the cold, cold garage was getting the best of me. I will settle for making the boxes in the shop and decorating the lids with the Glowforge.

Although I still might do one or two from inside ![]()

That dado blade…

Or you can go really old school, with a Stanley multi-plane. I don’t use this often, but it comes in handy, now & then. I’d sharpened the blades when this pic was taken, but hadn’t done any cleanup of the plane yet.

You could just build a very efficient dust collection system, then you can do everything in your office. Thats what im doing! If people walk in they might get scared though cuz the hanging plastic kind of makes it look like a murder room from dexter haha

me likey, me wanty

I swore I saw a box with a sliding lid on a glowforge collage shot of projects, but I can’t find it. It was something I’ve wondered about too.

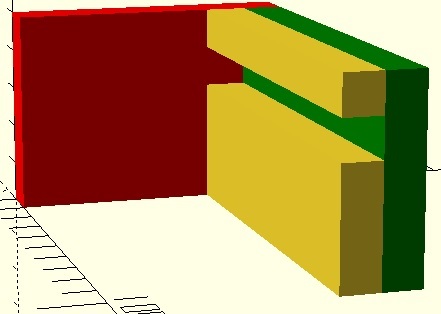

All that wondering, plus a maximum thickness of 1/4" for materials, has led me to the conclusion sometimes you’ll have to throw out your traditional approach to woodworking. I know, I’m a heretic; use your favorite 3D software package to design a glowforgable stake for a Friday night burning. Instead of cutting a groove with a table saw, cut an outside piece and cut an inside piece. The outside piece is solid and the inside piece is two parts, like this:

Glue and clamp. You’ll be making high quality plywood. You can always place a cap piece over the edges.

It’s just the path I’ve been going down.

I’ve been getting the feeling that I am going to be needing a lot more clamps around here soon.

I’ve been looking online for good clamp pricing.

Ive never had luck online. The lowes near me commonly has this for $20, which is about half of what ive seen it listed online:

$5 bucks apiece for those is a great price.

Dont buy that type from harborfreight, but they do have an all metal slide adjustable with a screw handle for tightening for $4.99 that you can put a serious hurting on.

You can probably do a deep engrave for the groove?

Or use slot and tab to secure the sliding panel. Cut slots in the green outer layer. Do this for both the yellow pieces that trap your sliding panel. The bottom yellow part would have to be made thin enough to laser cut the tabs that fit the green material’s slots. It would add the “signature” laser made effect to the sides of the box. I don’t mind that at all.

I splurged and bought 12 harbor freight clamps different sets of sizes. All broken! Still have my first set of quick-grips. Still good, except I have lost the tips to one of them.