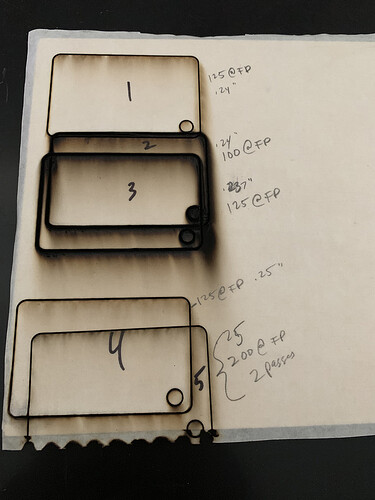

I’ve had my GF for a few days, so I’m still trying to figure things out. I cut up some plywood of different varieties and want to use the pieces in my GF. Some of them cut perfectly, no problem. Other pieces won’t cut all the way through. For example: I have a piece of 1/4 baltic birch plywood that I’m testing on. I’m using a digital caliper to measure the thickness of the materials. The baltic birch reads about .239 to .25 inches thick, depending on how hard I pinch the calipers (this thickness includes the masking film that I put on the surface. This piece is pretty flat, I don’t detect any rocking when I lay it on a flat surface. As you can see in my photo, I tried cutting a shape 5 times, with 5 different settings. None of these shapes cut all the way through. In fact, the back ply is completely intact except for attempt #2, where you can barely see some of the lines. And sometimes, the GF cut the shape in the wrong place and overlapped my other attempts. Can anyone give me some guidance? I bought this machine thinking that I could use my own materials, but right now I am feeling pretty defeated ![]()

This is going to get bumped over to beyond the manual, since it’s your own settings and material.

Be careful. Number 2 nearly caught the material on fire, it looks like.

Regular plywood has multiple layers of wood and lots of glue making it harder for the laser to cut through. When you buy the proofgrade plywood you’re actually just getting some hardboard with wood veneer on it, so it’s easy to cut through.

You can use your own materials but you’ll have to slow the cut speed down, and experiment with laser strength. It’s possible. I would make a small grid where X value is speed and Y value is laser power. Cut your grid on your custom material and then you’ll see which one to use.

Non Proofgrade materials vary widely and some work better than others. I suggest you read through this section from Glowforge support and continue experimenting. https://glowforge.com/support/topic/first-three-prints/working-with-manual-mode

For what it’s worth, I use about 125/130 speed, full power on 1/4” Baltic birch. I usually set the focus below the surface at about .208” (with a Pro).

And your material needs to be either dead flat, or held down down flat, especially at those thicknesses.

Everything already said, plus clean your mirrors.

Yeah, the big issue there is there are almost no standards when it comes to plywood/mdf cores. Dan talks about a piece of mdf he bought that they couldn’t cut through with a 100W laser!

So, with new materials it’s always best to do a test. There are a number of patterns to use - my go to is this one: Proofgrade Ply Samples

Start with the proofgrade settings and go up or down from there depending on how close you get - for a lot of things the default will work perfect, other times…

I’m sorry you’re frustrated and having a tough time with the ply. Take some solace in knowing that non-proofgrade material that works in other lasers WILL work in the GF too, I promise. ![]() It does take getting the right material and fine tuning your settings though. Hang in there and keep at it and I promise in a few months you’ll know enough to be helping others.

It does take getting the right material and fine tuning your settings though. Hang in there and keep at it and I promise in a few months you’ll know enough to be helping others.

Like others have said, plywood can be tough becasue of the different glues the manufacturer might use and other factors. Sometimes knowing exactly where you got your plywood helps to pinpoint the problem as a lot of folks have successfully cut ply from Home Depot etc.

As far as the overlapping cuts, it might help to share the file and maybe a screen shot of the GUI. There’s a few different reason it might be happening as in wrong material height or issues with the file itself. Without more info it’s tough to help with it.

I found this article good for understanding about the plywood issue.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.