Hi friends

It’s been a long time since my last post, where I asked to show you how to work with Glowforge.

I learned a lot, experimented and produced all sorts of things.

And today I’m happy to share with you my ups and downs.

Receiving

I paid for the GF during the pre-order campaign and waited like everyone, for several years.

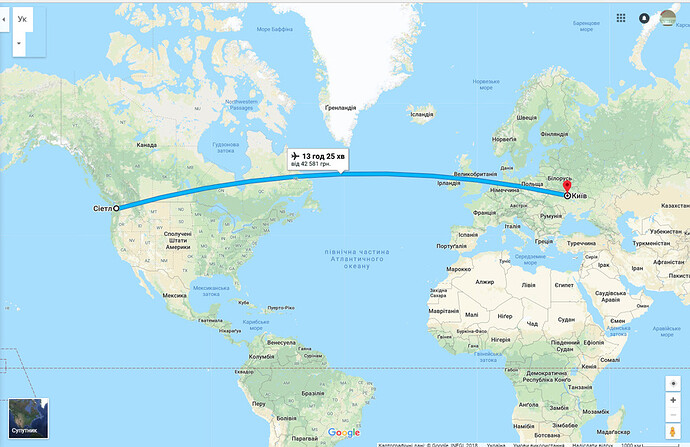

During this time I have returned to Ukraine (eastern Europe). I hoped I would take my GF after a trip to the US, but the wait was a bit longer (((

So I was waiting

And waiting

And waiting

And I received my letter of happiness !!!

But I was not in the US!, so the GF came to my friends. And they sent it by the DHL to Ukraine.

Now you realized how much I wanted to get this miracle)))

Beginning

Work began on arranging a place for the GF

The most important thing (in my opinion) is to set GF correctly.

If you do that, then you will not have any problems to close the lid.

Problem

I also want to warn many people about the problem that may arise

This problem occurs if your material is too wide and it would interfere with laser carriage rides. If on the one hand there is an obstacle, and on the other is not, then the carriage will continue to move and all will brake!

Thank you to the GF team for the fact that they have designed the bottom mount well and this problem is easy to fix.

Advice

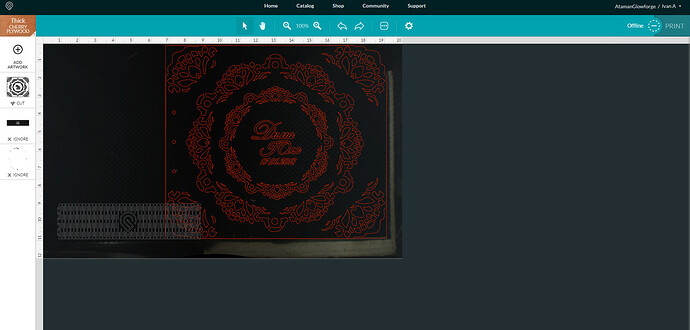

Working with the work field is quite complicated. You need to focus on the image from the camera (Since the image is with some distortion of space, you can not correctly set the print area.

The exit that I found rather simple - drew a workspace in Illustrator and very often it was used to center the new project.

What I also did, it clearly marked the boundaries of the “working area”, by marking the corresponding lines on the cardboard.

It turned out to be very useful

Projects

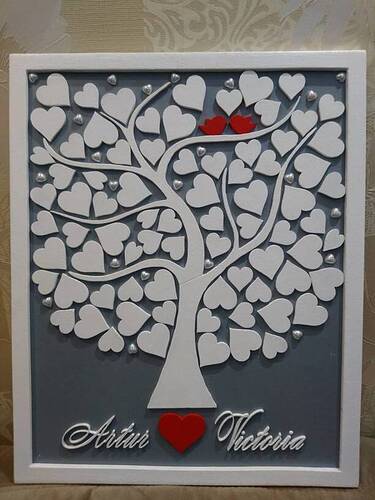

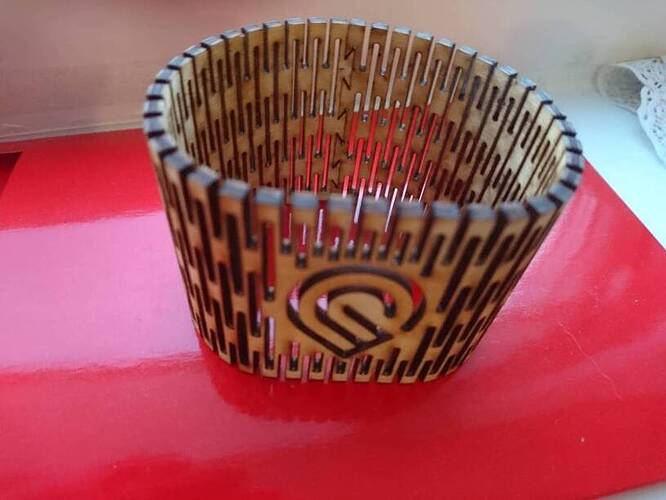

During my time with GF, I made a lot of projects, and some of them I’ll show you.

Various emblems, 550x500 mm in size

Picktures

Hangers

Tops

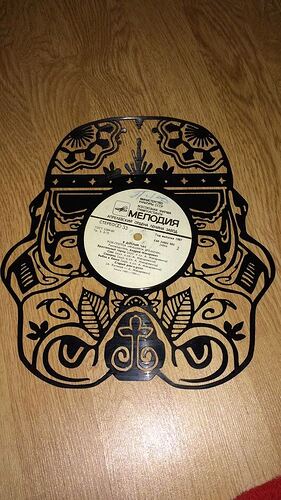

Vinyl Clock

What I am especially proud of is a puzzle box.

All connections I have developed by myself. GF in this project is a very cool machine)

Also, I was very fascinated by a lamp made of cardboard, which was in the video on the GF.

This is my first model and he turned out not quite as I wanted to see him, but he is still cool! (Although I will convert it to normal because the customer waits)

For paper products, I make special molds and all the following products I already make according to the typewrites, so i not to use GF every time.

After making a planet-lamp, I will make a bad for the cats

And I’ll make a puzzle bad for pets.

How to do it, I know. My cats are asking me because the present crib is very small

Yesterday it was a little sad because I did nothing new for a week (

So I quickly designed a gift for miself!

It turned out cool !!!

Conclusion

GF is a very cool machine, but it needs a lot of work skills. On it you can do a lot of cool things !!!

I am very glad that I did not take money and all the time I waited for my GF.

P.S. GF team, can I put my projects in the GF store so that everyone can buy them and do it all by themselves??? The project will include a video

Thank you all)))