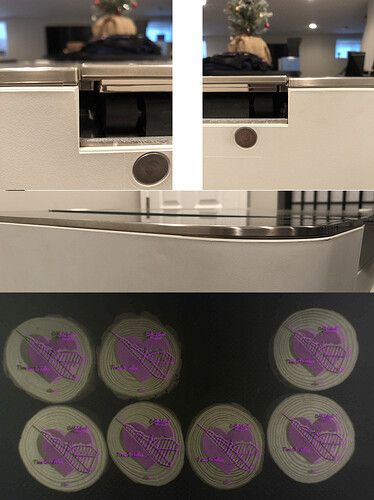

In the image attached, you can see where I meant to engrave and where it ended up engraving. Also, see how high the lid is. Could this little misalignment be the cause?

A Glowforge’s CS rep told me that it’s common for that to happen on materials that are provided by other vendors and that Proofgrade materials should print perfectly every time.

Does anyone else has experience with this?

Thank you!

Almost everybody’s lid is a little imperfect. If it doesn’t close all the way (e.g. if you push on it and it moves), it could certainly contribute to misalignment. One thing several people have noticed is that it matters a great deal whether the table you put it on is flat. The Glowforge case flexes a lot and this can make the lid not close properly. Try lifting up one of the front corners and you can see how much it affects the lid. On my old desk, I had to put a shim under it to make it work a bit better.

Of course, at the moment anything up to 1/4" is considered within spec, and it doesn’t look like yours is off by that much. It’s just the nature of the machine, at least until/unless better image processing algorithms are deployed. Precision placement is best done by first cutting a jig. You can find many posts on this forum about how to do that.

And alignment can be off even with PG materials, and spec is up to 1/4", so that rep really misrepresented things.

The fisheye lens is biggest factor–most accurate is right under the lens, and the further away from the center, the more shift.

If your thickness for the actual material used is not accurate, that will affect the focal length and contribute to differences between intended and actual alignment as well.

It’s difficult to get perfect alignment on irregular shapes, but fairly simple to use a jig for simple shapes and get excellent results. There’s a tutorial that discusses the process of incorporating your engraving into a design here:

As was mentioned above…it is critically important to measure the thickness of non-Proofgrade materials and enter that into the Unknown slot. The algorithm that corrects for fish-eye effects relies on that number being correct.

(Oh, and my lid has at least that much offset height…pretty sure that’s not contributing here.)

I would spend a bit of time to make sure the surface the Glowforge sits on was very flat even if you need to get some 3/4" plywood to put under it.

Having done that making sure the lid is completely closed is necessary. It will do little good to measure the thickness of the material to the third decimal point if the camera lens is at a slighted angle or an eighth inch higher than is calculated either of those things could throw the calculation of where stuff was way off.

A good solid flat and level base for your Glowforge is essential. But, I recently discovered a tiny piece of waste PG material which was keeping one side of the lid from closing conpletely—likely from cutting things like this and then lifting it out of the Glowforge bed—while raining “chaff”. Look carefully underneath the sides of your lid!