Yes!! I have been hesitant to purchase replacement parts because we’re still under warranty! I just hope they reply soon ![]() Our second GF is on the way now so hopefully I won’t have to cancel too many more orders.

Our second GF is on the way now so hopefully I won’t have to cancel too many more orders.

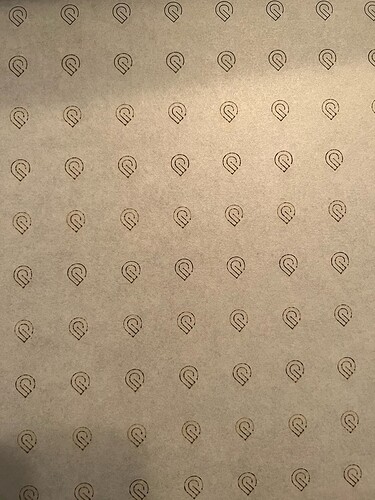

Hmmm. These are done as scores, the laser should be on steadily for each symbol that’s printed. Yet there are clearly spots where the laser power is basically NIL.

I think this looks like a power supply or some intermittent connection issue.

Thank you all for your help and feedback! I think I’ve come to the conclusion that this is not something I’m able to fix - out of my depth ![]() BUT I have been able to figure one thing out. If I do each cut singularly and power off the machine every few cuts (about 6-8 mins of run time total) it works perfectly. So that makes me think something is overheating/some kind of power or connection issue as you mentioned! But at least I am able to chip away at some orders while I wait on GF support.

BUT I have been able to figure one thing out. If I do each cut singularly and power off the machine every few cuts (about 6-8 mins of run time total) it works perfectly. So that makes me think something is overheating/some kind of power or connection issue as you mentioned! But at least I am able to chip away at some orders while I wait on GF support.

I appreciate everyone who has helped so so much!!!

I’d pop the machine open and reseat every connector I could find (including the ones going to the laser tube - after giving the power supply plenty of “off time” to bleed off any remaining charge).

They are supposed to be very light and you need to let it run till finished. Printing the logos is just the start it may take as long as a couple hours after that to finish, often less.

If the “measure thing”(GOGM) cuts well it might be the design. After you have cut a whole sheet and had problems put your hand on the print head after. If it gets too warm it should pause, but if it is warm to the touch that could be the issue.

I would also look to anything that might affect the airflow from the carriage fan (behind the gantry) I have even seen pins or some sort of drop-off interfere with smooth airflow and cause those flame ups. I was using magnets for hold downs at first and the magnets messed with the carriage fan and cause the problem.

Any time you see that flame it will interfere with the beam and will not cut as deep there. It was the flame and not the beam power that does that.

I don’t see anything wrong with that calibration print. As stated above, they are scored lightly.

Hey there, I was comparing my scores to both @Deleted’s reference photo and the initial calibration I had done a few months ago. The scoring was smooth/not choppy as it was on this print. I completed the entire process ![]()

I sometimes use honeycomb pins to hold down material but never magnets, at this time I can’t see anything that could be messing with the air assist fan.

The concerns with uniform power that I was noting were more attributed to the wobbly or too deep engravings I see on a multiple print job. However like I mentioned, going one at a time, I get a perfect print and cut. It’s all just so confusing to try to track down where the actual issue is coming from.

I did notice a crease in the white ribbon that plugs into my printer head. It doesn’t seem to affect the way that the carriage plate moves at all, but wondering if it could cause power issues?

I have seen them not cause a problem but I have also seen them simply have a crack in the metal and be very episodic and eventually failure and never know specifically where the crack was.

It occurs to me that a careful check of the rubber wheels might be in order as well. I have not had that issue but again those who have reported a wobbly path to a mess when they broke.

A moment-to-moment change in depth, and particularly the smoke catching fire I have always found to relate to airflow interference or bad materials.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.