I would have to actually do it to determine that; it’s kind of a matter of trial and error, not something you can dial in. Although I can pretty much guarantee that at 270 LPI it will likely burn all the way through the 1/32" Proofgrade veneer I have here. When they get the low power settings optimized I think we will be able to engrave veneer without burning through it.

Thank you

I don’t think this is the case… Or, to draw it out, when I choose 1000 DPI in JobControl I’m 90% sure it takes 1000 swipes in an inch, I’m guessing choosing 270 LPI in the GFUI means it take 270 swipes. In other words: I think DPI = LPI (though, “LPI” is a more accurate term for what is happening)

The other interesting thing is output/$ seems consistent, in that you could produce 5 of those squares on 5 GlowForges or 5 on 1 trotec.

The trotec has an optional camera attachment…

It’s a $6K upgrade.

I see the practicality of your conclusions in the performance of my stepper-equipped CNC mill and lathe. Pros denigrate it because the steppers on each limit the rapids to something like 150 ipm vs a servo-equipped machine with rapids of typically 1,000 ipm (I’ve heard of some that do 4,000 ipm). That’s all well and good if you spend all day doing rapid moves but I find that my machine jobs are probably running 90% at 65 ipm or less so the limited rapid speed doesn’t detract a whole lot from the job run time for me.

Perhaps the GF will be similar in that respect? From what I’ve seen on RDWorks Learning Lab videos most cutting with 60 watt or less laser tubes is done at speeds of something like 5 to 100 ipm and even engraving is 500 ipm or less. The GF with its 40 or 45 watt tube would be a bit less and the maximum travel speed even less of a limitation. If job speed is an issue, you might be better served with a more powerful tube than with faster travel speeds.

$3k. The $5k glowforge is the pro version, not the basic one. The pro one is 15% faster. Or more efficient. Are those the same thing? I don’t think they are. I’d do the math, if it mattered, but I can’t and it probably doesn’t.

There are always trade-offs between price and performance, and it’s pretty typical for the returns to diminish as the price climbs higher and higher.

Hey cynd11,

Sorry for any confusion. But I’ve been using a Straight up Square. No design just a Solid Black Square. That’s the times I’ve been basing everything on, the image was purley an example for another point I was making!

Thanks!

It looks like a 2.5" square would take 10:20 to engrave at 270 LPI or 12:55 at 340 LPI.

Perhaps this post is unneeded, but adding for completeness anyway.

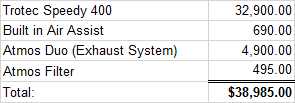

I serendipitously found a current reference for the price of the Trotec Speedy 400 that I trust.

So – six GF Pro’s with airfilters for the price of one Speedy 400…

Thank you for finding the current pricing.

This helps to get people to compare a top end Cadillac to a Lamborghini. They can get to the speed limit in town and on the highway (getting you from Point A to Point B). Both are nice, but there is a major price difference.

Is anyone interested in doing a detailed comparison between the two machines? I know I’m not. Work area (and volume)? Tube life? Portability? Looks? Ease of use? Track record? Speed? Power? Options? Resale? Cut/engrave quality? Mod-ability/upgradability? User community? Warranty? Power consumption? Noise levels? Safety features? Accessibility (as in: browser based or software based)? Availability? Setup time?

If we are going to compare these machines - let’s REALLY compare them. If we aren’t, maybe just sticking with the “how long will it take to do job X” topic might be more useful.

K40s are, like, $250, right? In the price:performance game that’s going to be a tough one to beat.

Mine cost me $350 delivered but I’ve put nearly $200 of upgrades into it - lens, mirrors, air pump, interlocks, red dot laser aiming, new head, Z-axis bed (manual), etc.

I have another hundred on deck for a conversion to Smoothie and open source software (LaserWeb). I think a really solid and useable K40 pimped out is probably $750. But the stock $350 machine was certainly usable to do lots of good stuff. The things I’ve done are more in the ease of use & performance/safety tweaking arena, not things I needed to do to get it to work.

A comparison to the Epilog Zing or Mini, Rayjet 50, or ULS VLS3.50 would make more sense as those all have work areas and tube powers comparable to the GF. They also use metal laser tubes and they all start at around $10k from what I’ve been able to find.

I’d be interested in a hands on comparison with the Voccell as well, but there are only a few of those out there in users hands right now.

A couple of months ago the Muse was of interest, but that interest faded quite a bit and I’ve stopped following them.