I see this confusion a lot, and it is understandable, since most people have experience using someone else’s laser, or a cutting service.

There is no magical setting assigned by default to any particular color. You have control.

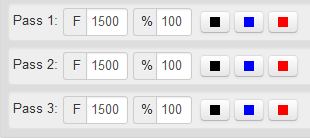

This is the interface on my laser. The image I have loaded has those 3 colors showing in the boxes as lines on the image. If I had more colors, it would show more boxes (and less if less). I choose the speed (F) and power (%) to assign, and select which colors I want to use on each pass. It shows 3 passes because I have 3 colors, if I wanted more I could add more (and cut one color multiple times or something). I can also assign multiple colors to one pass/setting.

The defocused laser is not yet implemented (last I heard). But it should show up in a similar aspect, as something you select when assigning power/speed.

Also… frequency is something in RF (radio frequency) lasers. The CO2 laser is a DC system, so we don’t have that setting.

Now… you CAN bake in permanent settings (the 1500/100 showing on each of my 3 passes in image is my default settings). You can include settings in the cut file itself, so that you do not have to remember them yourself. But ideally you save the file in a manner you remember what material to cut with (so filename says material type and thickness, or you have it in a folder for that material type/thickness).

What defocusing does for you, is just give you a larger kerf, and reduce your maximum possible power. So whenever you would want to hit a larger area… that is a defocused laser application. The lower power is a tradeoff you have to make, not what you are seeking, because you can just set a lower power, or run the laser faster over the surface for the same reduction in power applied. Defocusing is specifically about getting a larger kerf (area in which the laser is acting on the material… so kerf isn’t quite the right word, as that means area of material removed in a cut, and you are rarely aiming for a cut with a defocused plan… mostly due to the loss of max power meaning you cannot cut through much of anything anymore)

Since defocusing means larger kerf, if you WANTED to cut, at a specific kerf, you would need to specify exactly how far to defocus. So ideally they allow us to set not just a toggle for “Defocus? y/n” but rather a distance “Defocus? ___mm”

Then of course we would need a lookup table to tell us how large of a kerf to expect for each position out of focus. The focal depth is known, and in the FAQ… I cannot recall it at the moment, but I believe 70mm or so. And our range of motion around that should be 1.5" since that is our cutting depth, and we should be able to focus on thin sheets of paper, or large thick blocks. Though you want to focus in the middle of a thick block, so maybe we only have 0.75" of range.

Either way, you have to subtract your material thickness from the range of motion of the focal point, and that is your available defocusing range, and will determine your potential altered kerf.

If you design a laser system to plan for defocusing from the start as an application, you can use a lens which is concave instead of convex. Then everything is defocused, and you get more “play” in the application. But I haven’t heard of such a thing being done.

To pair with the greyscale engraving, I hope we can set the defocusing to be dynamic along any one line or gradient. Because then you can cut caligraphy (a line which changes in thickness as it moves) type of works. But again… that depends on how the team implements things when they design the feature.

would see this being implemented).

would see this being implemented).