When I cut small delicate designs it starts out with a heavy cut or burn that does not go through then changes to the correct intensity. This forge is less than a week old.

It looks like your focus is off for a bit - which is not supposed to happen. Support will get to look at the logs in the background now that you’ve opened a ticket

In the meantime check to see if the lens is stuck/dirty/has something in the tube with it. The lens moves up and down within the tube in order to have the correct focus, so it might be getting hung up on something in there…

Instructions are here:

Hit both the lens and the mirror sections (Things that need wiping & Wiping the Mirror in the Printer Head)

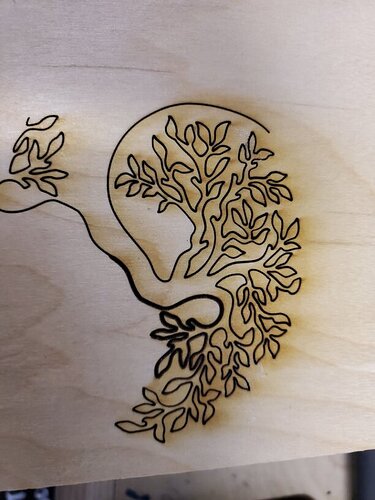

(Pretty tree  )

)

Also try that cut again on Proofgrade. There can be variations in lumber that will affect how the results turn out and you want to eliminate that as a cause.

If it does the same thing on the Proofgrade material, look at the file.

(This is a process of elimination that you need to run through before assuming it’s something with the machine. Of course it might wind up being something with the machine, but eliminate the other potential causes first.)

Now the bad news - it might be design related. The machine has to slow down for tight curves and switchbacks, and that design is full of them. You might have to modify the design by specifying a starting point on one of the sweeping open curve areas. (Do that by placing a cut in the closed path there.)

I cleaned everything including the interior mirror. Doing a test now…

The interesting thing is that it always does it in the beginning. Even if it is a straight or slightly curvy line like in the photo. And although it is scorching the wood it is not cutting through.

That’s a dial in problem with the software then. Do you have the speed update?

Yes I have the speed update. What is even odder is I do not have this problem with the larder version.

Yep, that’s something that tech support is going to need to look into. (Catching bugs early is good.)

In the meantime though…since you probably don’t want to wait for them to find it and fix it, you can try adding a lead-in tail to the design to let it get started somewhere off of the final cut that you want…it will expend that extra energy that they’re using to pierce the material.

Watch it while cutting. Two kinds of things happen with plywood . In one difficult places in the plywood get "special’ treatment sometimes filling where there were knots in the lower layers of wood, others it seems just wiping off the tool. in either case the fill needs a bit more power or a lot more power to make it through the fill and that will mess up the cut.

The other thing that happens is the combination of flammability of the wood combined with any reduction in the airflow created by the head fan. There are several things that can change that airflow. Magnetic fields can have a bad effect on electronics, and especially fans as they are moving very fast, or would be if the magnetic field did not mess that up. Anything like even a bed pin that the fan will not his will still mess up the airflow and if the hot gasses are not moved away from the laser hit fast enough , they will ignite into a flame, and the flame will scorch and smoke the wood, on top and not cut as deep on the bottom which scatters the energy and often not cut all the way through.

Did you get the situation with multiple passes figured out? Not saying it is multiple passes but it looks like what multiple passes would look like. If the paths are disconnected in the design, or an old, remnant duplicate line remained, that could certainly do it.

I’m so sorry to hear that you hit this snag. I appreciate you sending over multiple images of your prints.

When you have a moment, could you please do the following?

- Turn off your Glowforge, then turn it back on

- We included an extra piece of Proofgrade Draftboard with your materials shipment for troubleshooting. Place Proofgrade Draftboard in the bed and load the Gift of Good Measure design.

- Set the score and engrave steps to ‘ignore.’ Print the Gift of Good measure using the default settings. Allow the print to finish.

- When the print finishes, leave the lid closed and wait until the fans stop and the picture of the bed updates.

- Check the completed print:

-

- If the Gift of Good Measure fails to cut, please let us know the date and time of the print

- If the Gift of Good Measure cuts successfully, please try another print of the design you saw the issue with, and let us know the results.

- If the issue still occurs, please let us know the date and time of the finished print.

Once I can review this print, I’ll send over the next best steps.

What are the default settings?

The default settings will change depending on what kind of material you are printing on. Print it on a sheet of Proofgrade (medium draftboard is fine) and specify that as the material in the upper lefthand corner of the thumbnail column if the QR code is not read by the machine.

It cut. But did two passes when I asked for 1 on my project again. I waited 6 weeks for this machine and it does not work right. Please send a replacement and I will cross ship this one back. By brother Jon Glazer has been using this machine for a long time and is as baffeled as you are.

Thank You

Julie.

The Gift of Good Measure cut twice??

Now but now it did 4 passes!

Okay @julieogle99 - some of that is a little bit confusing, if you want us to suggest something else for you to try, I need to clarify a few things…

- Did you cut the Gift of Good Measure on Draftboard? (yes, no)

- Did that file cut through? (yes, no)

- Did it cut through without the doubling up at the start of the cut? (yes, no)

- Did you then cut your own file on draftboard? (The one with the wiggles? yes/no)

- Did that file cut the start twice, or the whole thing twice? (just the start/the whole thing)

- When you ran it again, did it just cut the start four times, or the whole thing 4 times? (just the start/the whole thing)

After clarifying these things, i can suggest a few other things that we can try, but I need to know what happened, specifically, each time you tried to cut it. Don’t mix them up.

You can just type the number of the question followed by the answer chosen out of the parentheses.

Update: Since the OP has opted to work directly with support on the problem, this can be ignored.

6 weeks is a really long time, i only had to wait 4 years.

I doubt she would have put her eggs on glowforge knowing that it was a 6 year wait. I am certain you got a discount on the wait for being a founder. So that means, really, nothing in this case. 6 weeks is a long time for an american made item to be delivered.

Did all that and it did fine. Think I figured out the 4 thing but it still cuts one more pass than requested on small detailed items which fries the wood.