No, I stole that from the update.

Have you? If the old 100 is now 90… isn’t there a range above that that you can access? I won’t get my unit till tonight so I won’t know what I missed on the old system but it seems that getting worked up about being able to access higher and lower power and not knowing where the old settings lie on that scale isn’t going to do much good. Unless you’ve been hoarding settings or you’ve been secretly using a PRU and not telling us

I think I’m reading the update differently than you. I took it to mean that precision power is what we have now, but with the low end unlocked. Full power is doing something different, which they aren’t saying what it is.

So, I guess there will be a gap between 100% precision power and full power, but its adding a new setting, not changing the old. I could be reading into it wrong though. I’ll play around with it more when I get home.

Could be. But you’d be guessing. Just like everybody else.

Plus, there’s no “thick” or “thin” wood listed. So I guess we no longer have anything that resembles a starting-point settings for 1/4" Walnut.

I cannot remember where, but there was comments that “max power” was not actually full throttle for the tube.

Now that “Precision Power” has been enabled, low end and presumably actual full throttle has become available. I base this on the references about the “Pause when warm” section of the July Update.

Pause when warm

Another feature that’s coming soon is the ability for your Glowforge to pause when it’s over temperature. Today, when your Glowforge is operating in a room that’s too warm, it just keeps going - even though cut and engrave quality may suffer. Thermal pause extends the lifetime of your tube by letting it cool down when the room it’s operating in is too warm, and ensures that long prints in a warm environment look as good at the end of the print as they did at the start. It’s pretty neat - the print just pauses for a minute (or more if it’s hot in the room), then resumes right where it left off. The improved cooling system on the Pro works with the feature so it can operate in a warmer room and pause less, too.

it is of course entirely up to them, but the ‘we know better’ philosophy of obfuscation is really frustrating

i had some thoughts about the manual, please feel free to ignore.

page 3: maybe consider adding a bit about looking directly at the point where ablation is occurring? i find this to be painful to look at to the point where it can cause after images depending on the power being used (but i admit that i am a delicate flower with sensitive eyes)

page 7 (the glowforge unit is a class 1) : consider changing glowforge to glowforge basic when discussing laser safety

(i think it’s not that strange to think someone may buy this, like it, choose to upgrade and not bother reading the pro manual since ‘i already know what i’m doing’)

page 11: will future glowforges come with a screw clamp? some recent production users have a different style clamp

page 17: just a thought; it may be worthwhile to have an alert pop up in the ui saying that it’s been 40 hours and you should take the opportunity to clean the lens and windows, if you haven’t done it recently. i get that this is an iffy thing though because you might not want to have users always rely on that since it’s going to be a variable based on materials.

page 20: consider adding another link to the forum here; i know you sneakily plant the idea when testing the connection, but people are more likely to act on this suggestion with a handy link or url

(apologies if i come across as rude, it’s hard to turn off editor mode)

Yes it could be that new 100 is the same old 100 but the new 1 is a lot less than the old 1 and full power is somewhat more. Of course it would be nice to know how big the gap is, but I doubt GF will ever say. It will be up to us to measure it.

Can I ask why it matters? (Genuinely curious not trying to be an ahole, you have a lot more experience with this sort of stuff than I do)

I am not getting worked up. I am simply enquiring. If they don’t make clear what the power scale is I will measure it when I get mine.

i suppose it is possible that there is a level between the two settings that would be better employed for specific situations, and it is curious that the power gradations aren’t simply linear. perhaps ‘full power’ mode employs some function of the laser tube and power supply that makes variability more difficult to dial in, and thus it is more of a turbo switch, like the button on my vacuum, than anything else.

I’m not guessing for thick and medium. I’m basing it off of the published focus settings for Thick and Medium materials in the GFUI, along with the standard thickness of materials provided by Inventables, etc.:

Thick Acrylic - 0.236"

Medium Cherry- 0.125"

Medium Acrylic - 0.125"

I think 1/16" inch is a totally reasonable expectation for “Thin” materials, but obviously YMMV. When they start selling Thin and Thick Proofgrade wood, they will add the settings to the GUI.

Ah, sorry I wasn’t intending to say you are getting worked up, but that is how it reads, that was supposed to be a general purpose statement. It’s an interesting and highly technical question and I’m just wondering why it matters. Are you hoping to take the same power and speed settings to a different laser with equal success? Or gauge tube health based on how successfully it cuts with certain power settings? Or just extremely curious about exactly what your unit is throwing out?

i think the best analogy is to think of a car. most people like to get in their car and go places; they are mostly concerned with the appearance, interior features, safety, etc. i’m not saying this to denigrate their preferences, as it’s a completely valid way to go.

others like to know the minutiae of the engine, the materials the car is built from, how to maximize performance on a track, it’s theoretical maximum speed and / or horsepower, how the brakes work in different circumstances, etc.

a lot of the time these two come across each other and simply by asking questions put the other group out of sorts, with some thinking of the car nerds as unnecessarily pedantic petrolheads and the car nerds thinking of the regular buyers as people who are blind to the basic functioning of an amazing piece of machinery.

neither is a wrong way to view the car, just different.

I want to make a detailed study of power versus cut depth, etc. I have a house full of CNC tools and I know exactly what the all do for a given input. I don’t see why a laser cutter should be any different. All you can change is speed, power and focus. I don’t see why power has to be obfuscated. Also curious why focus has a 11mm range instead of the 1/2" promised.

My point there was you had to look to know that. Whereas yesterday it was right there… completely obvious for you (us).

My point there was the settings were there yesterday and have been removed. I used the 1/4" Maple Plywood setting all the time.

Fair enough, and what will it tell you when/if you can get a lock on where the old settings fall in the new scale? I always assumed that the old power settings were a “training wheels” mode that matched the limited x and y axis travel. They didn’t want to over stress the beta and PRUs. If those numbers won’t ever find their way onto your machine, and you’ll be able to do your detailed speed and feed chartings with your unit and the UI you were given, what answers lie in the training wheels settings? I’ll be happy to throw a couple small burn tests in for the sake of science if they won’t waste too much material and you’ve got something specific youre looking to see out of the New UI and a fresh production unit

I have a question about Draftboard: What does it look like? Is it like “laserable” MDF? Does it have a pretty smooth surface like MDF or coarse like particle board? Is it darker or lighter in color?

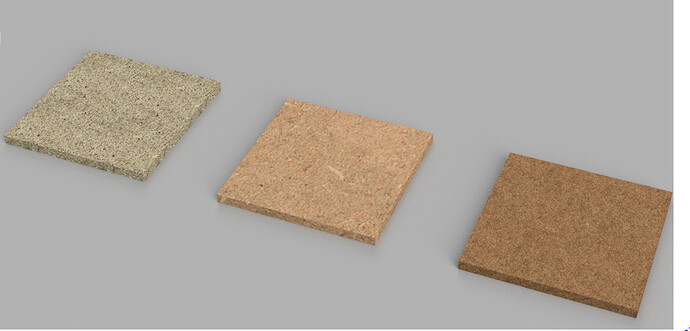

Essentially, If I was to pick a material in Fusion 360 to emulate it, would it look more like the particle board (left), MDF board (center) or hardboard (right) or something else altogether?

Also, someone should make a set of appearance textures that we can import into Fusion 360 for all the proofgrade material. That would be awesome!

I also assume the draftboard comes in different thicknesses?

Thanks.

Can’t wait to try it out!

Folks my age are often stereotyped as resistant to change. It’s one of the reasons younger employees are often seen as more desirable to a company versus more experience. Should take 5 minutes to adapt.

My main point of interest is how low 1 is and how high 100 is. I presume full is actually 40/45W.

Where the old settings were would help current users converting. My only interest in them is curiosity in how it has changed.

Also

page 19: still reads “Insert the small white foam block over the white tank in the front left of the unit.” Instead, only realize the truth… There is no block.

I do see, however, that the line about removing the block earlier on was removed from the manual. So that’s cool.