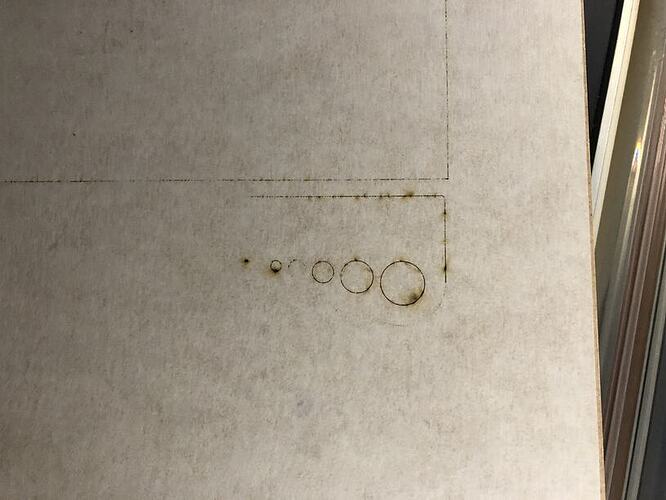

I hate to post here. I am also having some issues with draftboard. I was having other cuts not go all the way through but they were not proofgrade. But they were with other settings found on the forum. I did clean the lenses. I used a level to check the crumbtray and material. The particular piece of proofgrade is .136 inches.

Have you tried slowing the speed? Sometimes the board is not flat. I usually slow it down from Profgrade settings just in case. You can run a test cut to find the sweet spot

I was under the assumption that proofgrade was foolproof, that using the official material and offical settings that they would be calibrated to work perfectly.

I was just posting to see if support could provide any additional information that they have access to on their end. I am interested to know what is wrong with my current setup that when I have the work level that the cut is uneven.

Materials can warp. Even proofgrade. I had the same problem because I didn’t lay my material flat well, I am a newbie.

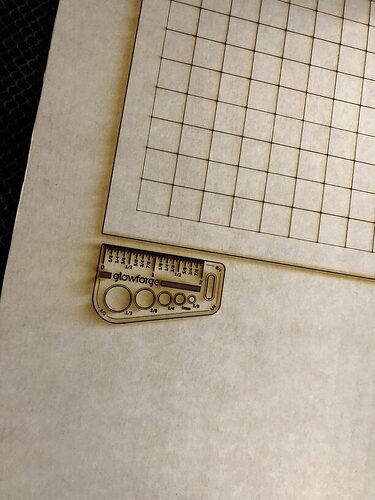

A user realized this and designed these Honeycom pins and 95% that fixed the not cutting through issue. The other 5% was cleaning the machine

That’s why I posted the photo with the level app.

It was flat. Maybe a variation in the density of the material?

I didn’t realize that was a level app, my apologies. Have you used your machine alot? I cleaned my mirrors and lenses when I had that happen and the material didn’t cut all the way through just like this

I finding using the GF is becoming more and more frustrating. I’ve had it a little over a year, and it’s gotten progressively worse. I find it rarely cuts all the way through anything anymore, or half of a design will be cut through, the other half not at all. I know of all the usual suspects, make sure it’s flat, make sure it’s clean, yada yada yada… Making test cuts are zero help because each piece of “proofgrade” is different. What worked with one design on such and such settings usually will not work again with a different piece. Make all the test cuts you want, you put in a different piece of wood, and you’re starting all over again. It’s frustrating and irritating. I’ve wasted so much wood making “test cuts”, and then when it’s time to do the actual cut, the “test cut” settings rarely work.

I realize this isn’t magic, and that it requires significant trial and error, but upon purchasing this thing so many years ago, we told that it would be “that easy” to get decent and consistent results. And that “proofgrade” materials were offered, at a higher price than you’d probably pay elsewhere, because of this ease of use. And yet, every time I want to use this, and make my test cuts, and then make my real cuts only to have it not cut all the way through. It’s really disheartening.

I’m not sure how sensitive that level app is. My “foolproof” method is to lay the material on the honeycomb and then tap it in different spots. If it’s flat on the honeycomb you get more of a dull thump; if it’s a hair off the honeycomb you get more of a click sound. Anywhere I hear a click, I stick a honeycomb pin or magnet, then I test again. When I don’t hear clicks anywhere, it’s good to go. I’ve found that even material that looks dead flat to the eye will have areas that aren’t, and checking it this way ensures I’ll get good cut-through (assuming I haven’t gotten lazy and waited too long to clean my lenses/mirrors!).

That’s what I normally do to. If I get a wobble on the tap, then I grab a few pins. I used the level app to show in a photo, since I can’t take a picture of a tap. Also I moved it to take the photo.

I wanted to document it on the forum since it looked like others are having the similar issues. To see if it as more commonplace. Or if draftboard tolerances are varying.

Sometimes this works, other times not so much. Sometimes you can only place magnets along the edges, making the middle much more difficult to get flat, depending on how you store your wood. As has been stated, even the most slightest of bows in the material will affect the resulting cut.

I keep my material as flat as possible when stored, and weighted down to prevent warping. I too secure the wood as much as I’m able with magnets, but sometimes that’s just not enough. Sometimes it seems the laser itself is inconsistent in whether or not one can get a clean cut all the way through.

I’ve gotten in the habit of, if making cuts, to decrease my speed. But even doing so, sometimes still doesn’t cut quite through.

I don’t have the money to waste proof grade so as I posted above I always change the proof grade settings. I have saved my altered settings and now I rarely have any issues. I do agree that GF might want to adjust their proof grade settings however. I also think it should be as easy as advertised.

I’d say there is a decent chance that a year in, if you’ve been using it a fair amount and subsequently cleaning it a fair amount, you have some scratches starting to appear on the optics. The optics are basically consumables. Over time, even with careful cleaning, they will need to be replaced.

I’d say it’s not so much the laser, as inconsistencies in the materials, the cleanliness of the optics, the power of the beam (the tubes don’t last forever at the initial power), and the warp in the materials.

I’ve got a warping problem here, always have. The longer I store materials, even proofgrade materials, the more humidity it absorbs. That increases the chance of not getting a complete cut. The proofgrade stuff has been consistently easier to cut than other locally sourced materials though, so as far as I’m concerned, it’s a HUGE improvement. Maybe not perfect, but I don’t ever expect perfect from anything either man-made or produced by nature. ![]()

Note: By the way @bwente, sounds like you might be having a similar problem with the draftboard expanding just a little bit from the humidity. I measured all my materials when I got them and ran an average of 0.130"-0.134" on things like draftboard when I first received them. Yours is at 0.136", and mine are running at from 0.137" to 0.139" after extended storage. So they are swelling a little bit. That will cause the default settings to need to be adjusted for a one pass cut to work.

Thanks for the material reference. Humidity is a long time friend of mine, born and raised in Florida.

I will try a test on some acrylic, that doesn’t seem to expand much.

All Medium Proofgrade materials are manufactured to be exactly 3.175 mm or 1/8 inches thick. As @Jules notes, this thickness can change due to absorbed humidity, which can also cause warping in certain materials over time.

@Bwente, please let us know how your test with acrylic goes!

I printed a gift of good measure using a piece of proofgrade acrylic and it cut out mostly, I had to push out one circle. I would say that I guess it was “expanded” piece of MDF. I would have thought it being level was enough, but I guess if it swollen equally in each dimension it would still be flat.

I would not assume that a level app on phone means the stock is flat. My iphone reads to 1 degree which sounds very accurate, but it is not. Also a surface can be out of level, but still flat (planar)

Thank you for this information! I’ve passed it along to the team to help improve our Proofgrade materials.

I’m going to close this thread - if the problem reoccurs, go ahead and post a new topic.