Tried my first large complex engrave today. Let’s just say it was a “learning experience”

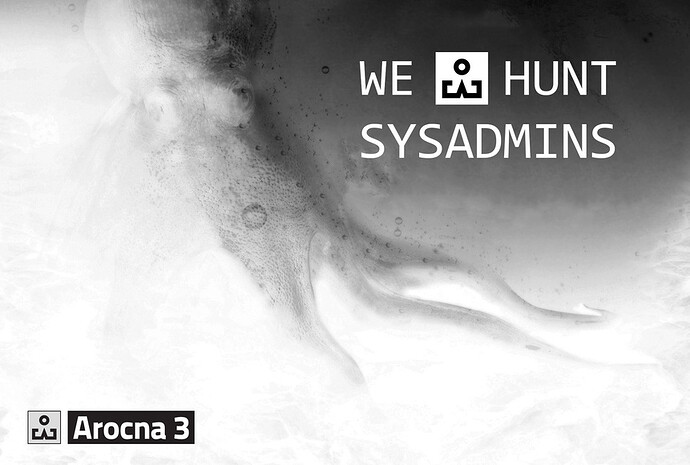

Source Image after I did some modifications:

First issue I ran into is the current app limit/bug on engrave size/complexity throwing an error during the “preparing” stage. Support sent me instructions for splitting and recombining the image into a multi-part svg made up of png components. Process was straightforward enough and I started the engrave of the pieces in stages.

Second issue I ran into was the “scanning material” hang that from what I’ve read in the forums recently may be triggered by starting a run very quickly after the previous run finishes. Tried opening and closing the door, powercycling the unit, but finally ended up having to refresh the app. This got me back to where I could interact with the job again, but since the app currently has the limitation/bug of not remembering the placement of the design, I had to eyeball the alignment. This brought up the third issue…

The third issue I discovered when trying to eyeball the alignment to restart the job was that the design and the actual outcome of the engrave were nowhere near each other, being nearly a half inch off at the outer edges:

This made eyeballing the alignment accurately pretty much impossible. I took my best guess, didn’t exactly nail it.

That’s the outcome with a lighter for scale. Had it not been for the hang and alignment issues I’d say it’s incredible. The aluminum sheet is 12"10" an eighth of an inch thick.

Lessons learned:

- The app today definitely isn’t ready for large/complex engraves. Even cutting the image into smaller parts is dicey if you run into anything at all that forces you to restart the app and have to manually re position your design.

- Alignment is SIGNIFICANTLY off, and appears to get worse the further you get from dead center of the camera. Until this gets fixed, it’s probably not worth trying to work with large designs.

2.5 Interestingly when trying to realign manually, the design ended up being a bit tilted, despite both the design file being the same and the aluminum sheet not moving. - The SVG I created made up of the smaller cut png’s from the original appeared seamless in both illustrator and inkscape, but I noticed I could see dividing lines between the pieces in the engrave. Only after I was done with the engrave did I realize this was my mistake. The first SVG I created was indeed seamless, but I decided it was too large to mess with shrinking in the GF app, so I selected the whole SVG in illustrator, reduced it’s size by 50%, and saved as a new file. Apparently the process of shrinking the SVG created hairline gaps between the pieces. Next time, I’ll resize the source image before I cut and rejoin into the SVG.

After running into some of these issues and searching the forum, I discovered some were already known bugs/current limitations. It would be a HUGE help if the GF team could:

A) Post a “known issues” section that prominently displays itself in the app. It’s no fun running into a bug or a limitation, but it’s even worse discovering that it’s something that was known beforehand and could have been avoided/worked around. Digging through hundreds of forum threads and taking notes isn’t a great solution.

B) Post a detailed changelog so we can know when these issues get resolved.