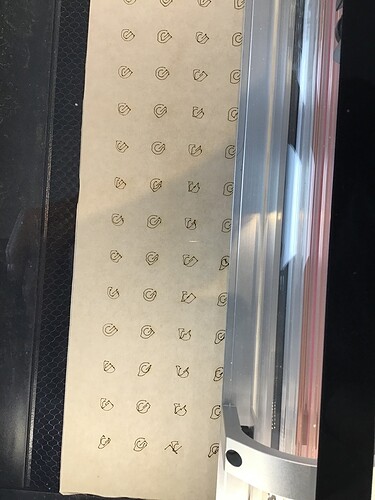

Could be a loose gear for the belts. Check all the belts and see if they are tight. Gantry cable ok?

Turning the glowforge off you can gently move the head and gantry and see where the issues pop up.

And welcome to the forum.

Yeah, I agree with @marmak3261…the belt tension in all three of the belts is the first thing I’d check. You’re going to need an Allen wrench to tighten them, and there are a couple of pictorial walk-throughs on what/how to check it here:

Thanks for the welcome. Sure is a nice machine, other than this (hopefully) minor issue. The belts are all snug although the loose gear idea makes sense. I’ll try that and report back.

Thanks!

-stu

I followed the outline in the links and the pulleys and belts are snug. One thing I noticed is the gantry has a slight “grab” in a few spots as I push it to the back or front of the machine. Not sure if that is typical. Is it possible for the pulley to spin on the motor shaft at all? Could it be a software issue with one of the two motors missing a step or stalling?

Somewhere there is a topic about a snag of cables, if I recall correctly. Something seemed to be hanging down. I think there was an issue with a bad v-bearing too. Keep checking and seeing if anything is sticking out or seems out of place.

Yes, I saw that one as well. I looked under while moving the gantry but didnt see anything. The bearing is a good idea. I’ll check into it.

It’s not. The movement should be smooth. Investigate that.

The mechanisms are pretty simple, so there is a limited number of possibilities. My money is on something mechanical as opposed to software.

By posting in this category you generated a support ticket.

If you have also emailed support, they like to close these threads and deal with it through email.

If that happens, please follow up with us in “Everything Else” what the resolution is. That would be beneficial for us.

Welcome, and thanks for joining us! ![]()

One of the steppers may be bad, though usually they either work or they don’t. The problem is probably “wracking”. The steppers drive a cogged belt. If one side is offset from the other, when they step the mechanism will bind/drag and you’d probably get this kind of “wobble”.

My guess, one side of the carriage assembly is one cog-tooth advanced from the other. You might be able to detect this by “plucking” the belts. They’re under tension and they’ll ring like a guitar string. If both sides don’t sound the same, the tension on both sides isn’t equal, and that’s where the problem lies…

Excellent ideas! I will check tension by hearing the belt tension first. Having one tooth out that starts a wobble really makes sense. If I have to pull the belts, or loosen them to adjust tension, would it be an idea to move the gantry without belts and see if I can feel spots of roughness? My thought is to isolate the areas of bearings/gantry, belts and steppers… Thanks again for the excellent feedback. It lessens the sting of spending $6000CDN and having a non-functional machine… cost more than my car.

stu

I’m so sorry to hear about the trouble with your print results. I agree that our first step to resolve this is to check your belts for proper tension. I’ve already replied to your email with instructions about the belts. We are going to continue to work on this there, so I’m going to close this thread.