(Dan insisted on that title ![]()

![]() )

)

So, not sure if this belongs in Made on a Glowforge because it’s not a finished project, but I was looking for some community input.

I was in need of a 45 degree angle on some wood for some various projects (will follow up with posts on these eventually) and decided to make jigs to get me there.

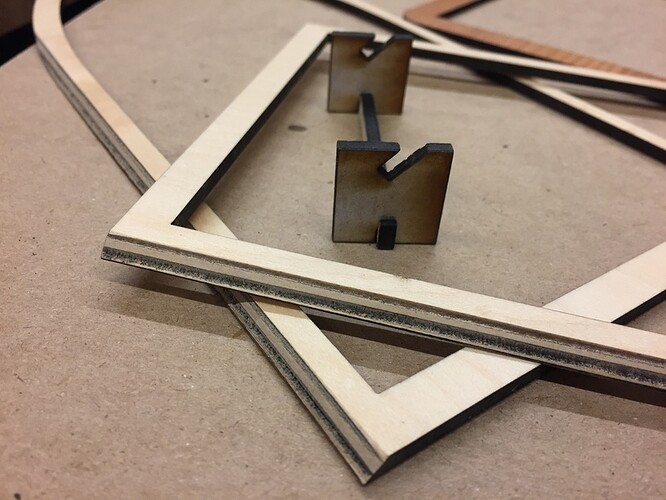

This jig was relatively straight forward. I’m going to glue these guys together at the corners to form a 90 degree angle, so I didn’t care about the looks of the sanded edge, so I did some engraving and More Aggressive Engraving ![]() to remove most of the waste material and make sanding much faster. The jig I made fits around the outside of the edge like so:

to remove most of the waste material and make sanding much faster. The jig I made fits around the outside of the edge like so:

and allowed me to sand the whole edge in something like 30 seconds. I was surprised at how quick it all went. The larger surface area of the jig relative the edge made it easy to keep lined up, keep pressure even on things and know when to stop.

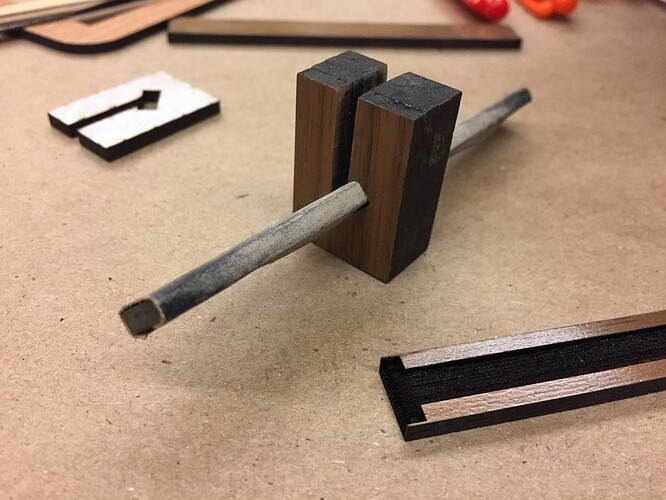

Then I had need of a 45 on wood with a finished outside edge, as I was framing the outside of a piece of 1/4 inch acrylic, but I couldn’t use the same concept because the length of wood was too long. I conferred with @madebynick for a while, and we came up with this little weird inside out jig for sanding a 45 on a longer piece of material.

(the sandpaper is folded-torn to size and I super glued it around another stick of wood)

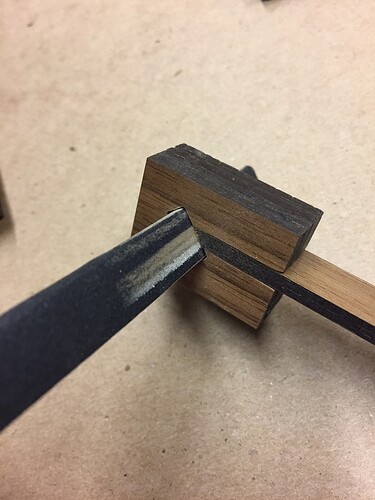

In this case I did care about the look on the outside edge of the sanding, so I left the outside parts of the wood un-engraved so that it wouldn’t have any accidental stepping. Unfortunately, that outside bit was a bit two skinny and tended to break off, but I managed to salvage things for the project. Next time, will leave more material there. The same jig in action.

I think the problem with this second one is that the jig develops a bit of a wobble, and I found that it wasn’t sanding perfectly evenly.

Would love to hear other ideas from the community on ways to jig angles and sanding!