My two young boys have been obsessed lately with the American Revolution, and so I decided to go with that theme for my next draft project; an engraved acrylic sign.

A HUGE thank you those of you who have posted this kind of project in the past; @smcgathyfay @marmak3261 armak3261 (apologies if I have missed anyone) like this: ProofGrade Projects and Pre-Release Glowforge :glowforge: mini acrylic LED sign - #18 by jamesdhatch

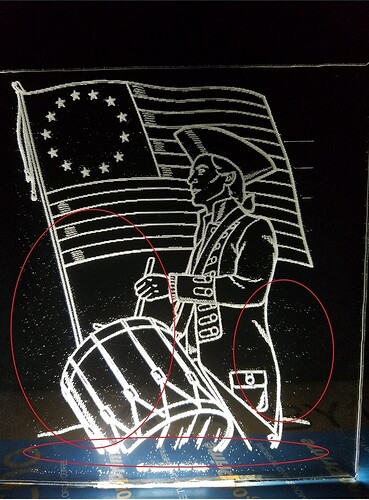

Please keep in mind that this was just a ROUGH test run, so it’s only 75lpi, the border was hand drawn & so it’s all wavy, I used an uploaded pic so it is a raster instead of smooth lines, and the pic I used has tons of noise…but I think it still came out pretty nice?

I think I might also have discovered a possible bug, which I will let Rita know about: The app had 2 choices for the engraving shade, and both choices seemed “blank”. I just clicked on one of them and figured I’d just see what happens…wanna guess, before reading the answer?

If you said “It went through the motions of printing, but did not produce a laser beam”, you’d be correct. I’m guessing that the auto settings must be blank for this p.g…

Has anyone else encountered this problem?

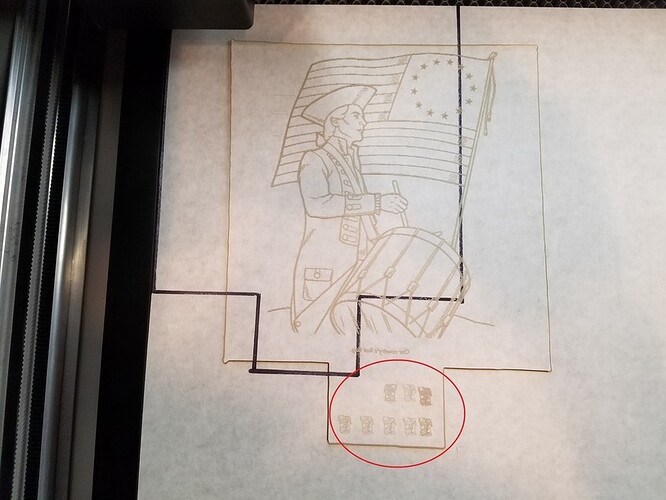

So I tried several tests using manual settings, and was getting weird results; sometimes it seemed to just remove the protective paper, and one setting was so high that it cut dots all the way through. You can see the tests here:

I finally wised up and looked online for good settings, and found 100 power and 90ipm, and that seemed to work well.

I also then realized that I needed to set the focus properly; I chose 1/16th, figuring that the center of the sheet would make for a nice, deep engrave…was that a good choice?

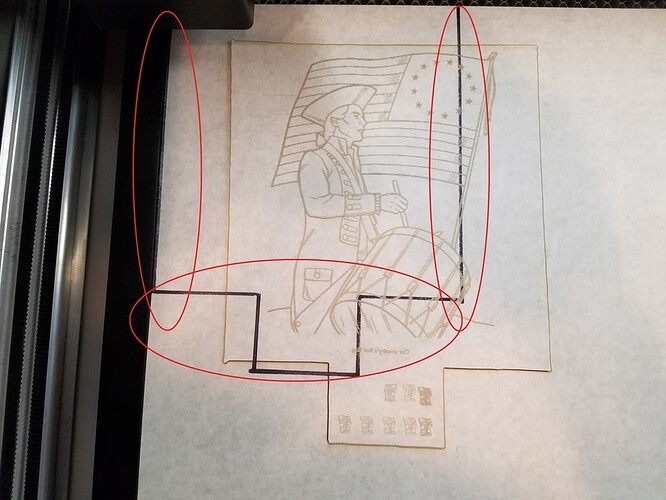

Another thing to keep in mind: I originally had drawn the border on the p.g. paper, with the very left edge included in the lines I drew, but the trace function was not picking it up because it was either too far to the edge of the bed for thee pre-release models, or because it blended in with the black of the bed (not sure, and it was soooo late at night that I forget now*). So I re-drew it on a piece of regular paper, centered it in the bed, and traced that instead. That is why the print is off from where it looks like it should have been…

Original maker that I could not use:

And this is the noise I was referring to:

By the way, the protective paper sticks pretty hard to the acrylic, and can be a little tough to get off everywhere, especially in the small, scratchy engraved sections.

And it can leave a film of sticky residue, even if it looks clean. I went to wash off my fingerprints with soap and water, and that is when the residue made its presence known, with a vengeance…

After I dried it, everything went frosty and I could see that the whole surface was slightly sticky and smudges everywhere…more soap did not help.

Soooo, I grabbed some lighter fluid and some paper towels, and after a short while and some rubbing, it fully cleared up.

I think next time, I will just soak it with lighter fluid (OUTDOORS & AWAY FROM FLAMES & LASERS; SAFETY FIRST!) for a few minutes while the paper is still on; that should permeate through and dissolve the adhesive, making the peeling a piece of cake, and then also much easier to wipe away any remaining adhesive.

Then a quick wash with soap and warm water, and she’ll be shiny & bright!

*A word of caution to all who haven’t received a unit yet: You WILL stay up very late at night, tenderly loving your forge, and not giving a single hoot about the inevitable coming sunrise…you will then viciously curse the morning for a fleeting moment, until you recall that you have a forge, and a new day means…MORE FORGING!! WOO-HOO!!!

UPDATE 4/7/17: Huge thank you to all who have taught me so much…

Thanks to the svg file that @takitus sent me, I was able to upgrade it to this!

Yeap, svg is definitely the way to go for beautiful, clean lines…I’m getting Adobe Illustrator for sure…

UPDATE on 4/10/17 - Added a wooden base…

Just a quick & easy (slightly sloppy) wooden base addition:

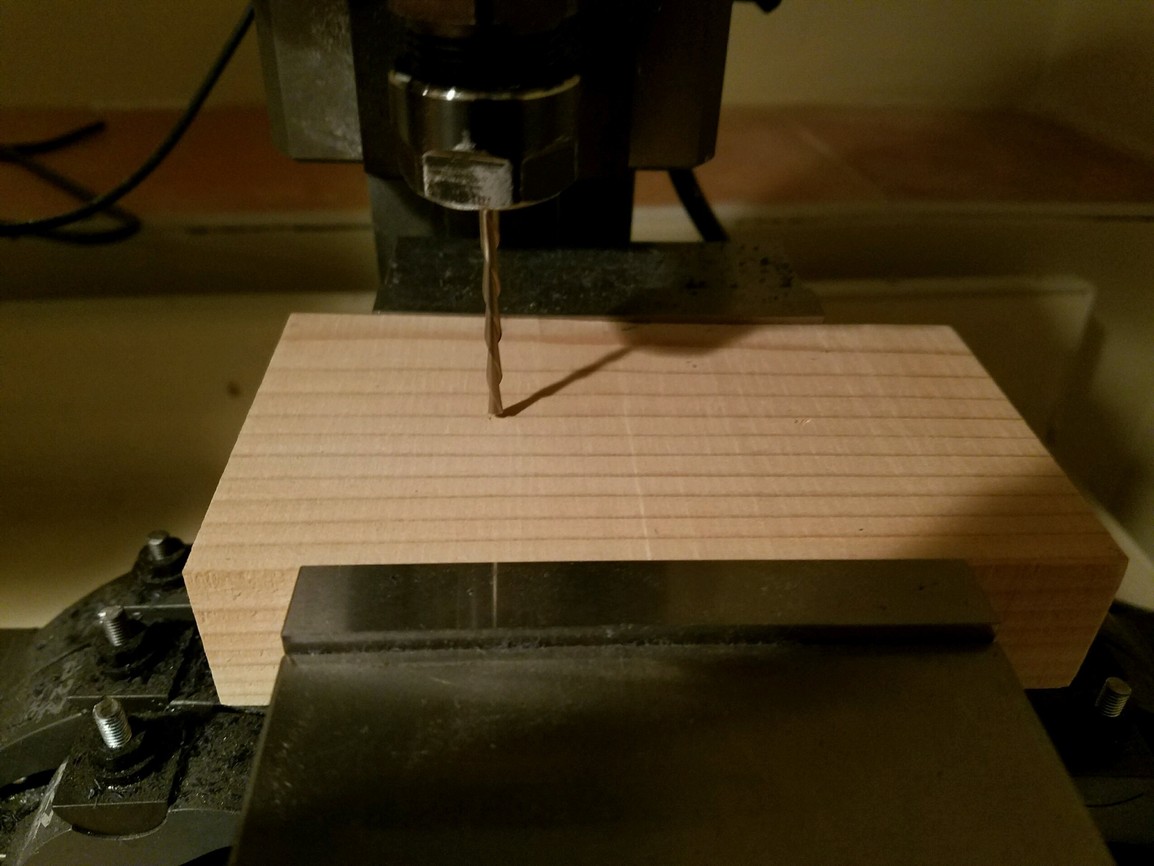

Could not find my real 1/8th end mill, so I used a dremel one instead. Note to everyone: Don’t use a dremel one instead, cause it bends, lol:

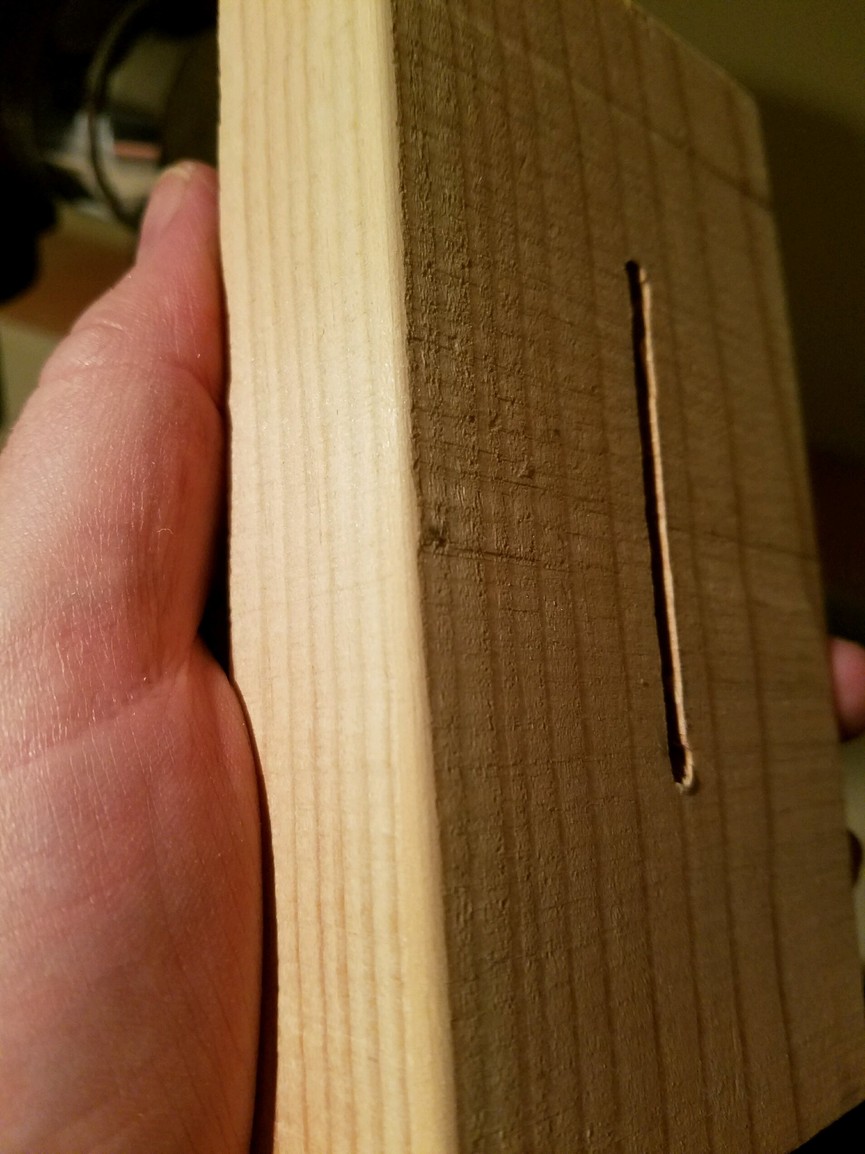

Sloppy cause it bent, but it fits nicely:

BTW, notice the rounded edge? Compliments of this little awesome guy; I HIGHLY recommend it:

Switched to a real end mill and milled the bottom for the wire & L.E.D.s, held firmly in place with Gorilla Tape:

Sitting on top of the wood base. I’ll take a pic from a bit further out later to show the full view. Maybe I will even paint it black. And this makes me think that it would be good & easy to use the paper / plastic composite that someone had posted about a few weeks ago; I received a sample of that; good stuff!

Btw, 3 LEDs were too bright for a night light, so the next day I covered 2.5 of them with tape; much better.