I think I am tracking what you are saying and I see no reason why it wouldn’t work. I am going to probably try a few different things and will report back with what I come up with

I getcha - in the case of this particular thread you’d have to get the heat press into the GF somehow to hit the base.

My heat press would fail  as it looks like this

as it looks like this

Lol, the circuit easy press comes in a lot of different sizes (I have a few) but my favorite is the circuit easy press mini, which is low cost and tiny. It actually is designed to be used to put HTV on your shoes and hats. I think this can fit…

You also do not have to use a heat press, you can use a house hold iron and teflon sheet.

But the points you are bringing up are great examples that support my statement from above that it is important to know your material. I appear to have a stronger understanding of adhesive and heat transfer vinyl then most but I still always look into the material I use.

So…one last try: Wavelength has nothing whatsoever to do with the issue.

The issue is that the laser still burns material even when it’s on the bottom of the machine. When you burn vinyl, even just a tiny bit, you release chloride gas that gets blown all over the inside of the machine and will gradually corrode and eventually destroy the electrical components.

One last try…not all vinyl is the same. Generalizing materials is not best practice. There are laser safe vinyls as we discussed above. I never stated the vinyl I use in my post and I never encouraged others to use vinyl. Even more so, I stated that although the grid I have at the base of my glowforge is useful, I am planning to switch to masking tape. I created this post to share information that I found valuable to the glowforge community. It is your choice to make assumptions from an image and negate the value in the information in the post.

What I was replying to was (as quoted in my response) your statement that since it was on the bottom of the machine you weren’t concerned with the laser interacting with it.

I am not disputing the fact that things that are not actually vinyl sometimes are labeled as vinyl. I am disputing your statement that the wavelength of the laser is somehow different outside 0.5" from the head than it is within 0.5" from the head, thus making the type of material used on the bottom of the machine irrelevant.

The wavelength is not different. The wavelength would only change if it went through a medium (which is not happening in this case). But the wavelength does not change from traveling the distance that is .5" from the laser head to 2" from the laser head. I never said that the wavelength changes. Instead of inquiring about what I meant in a statement, you made your own interpretation and assumption.

Ah, I see where you might have made assumptions from my statement. I agree that I sometimes phrase things a little oddly and can see how it can cause confusion. I always am happy to clarify what I mean when I say things. Never hesitate to ask

So for one of my glowforges I decided to have it cut out a 10x18 grid and I used a sharpie pen to mark where I need to line it up at when on the base. Sharpies come off the base with magic erasers and so I am fine with this way of doing a grid at the base. I think there are many other creative options out there though.

Hmm you could make a vinyl or mylar stencil and align it on your base, then use sharpie to mark the inside of your GF with a semipermanent grid, then remove your stencil… Added benefit: zero height, so it won’t interfere with the crumb tray in any way.

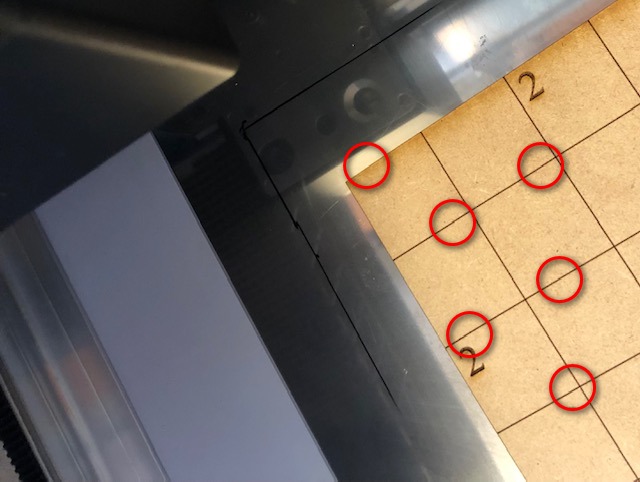

I looked more closely at your grid picture, and I’m more concerned about these spots:

Is that an artifact in the picture or do you have little jaggies there? If it’s not in the original artwork your GF shouldn’t be doing that. It’s almost like the GF is skipping or something, maybe a problem with the stepper motors, wheels or rails?

Interesting, I hadn’t noticed that. I will do some tests with it. The grid was made on the glowforge I got in last month and so it is brand new so I certainly will look into that. Thanks!

I like the way you think! I was thinking to just use a ruler to draw lines but making a stencil to use will be much more efficient.

(Late to this party) There are sheet plastics with the word vinyl in them that are not actual vinyl and advertise them as “laser safe” but you need to treat them like something sold as a scarlet snake that you really want to make sure is not a coral snake as the difference is similar. There have been photos as has been noted before.

I bought a few things from them, There was an Android tablet that had two phone lines built in. The phones never worked but it was my go-to tablet for quite a while. and might work still if the charging port worked.

Check out this wicked previously:

From prerelease days!

Wow even earlier from 2015, the 76th topic!

This discussion is #93,667 by contrast.

Here’s the original support ticket for that guy who repaired his pvc damage:

Anyway, I was looking for a post that I remember where a user cut PVC on their very first job and destroyed the machine. Can’t seem to find it, anyone else remember it?

That might have been me…

I had my GF for less than two weeks when I cut the PVC.

I cut, engraved and designed a really cool laptop bag out of alligator molded PVC from Jo-Ann Fabrics.

Spewed HCL all over the inside on my machine.

Dead within the first two weeks it arrived at my door…

Believe me…I WAS VERY UPSET…first at GF…but then at myself for not doing the proper research…

When given a choice of spending another $2000 to get it repaired or tossing the GF in the dumpster…you’d be surprised at what you can accomplish when your willing to throw away a $6000 machine that you’ve had for less than two weeks…

Thus…RECOVERING FROM PVC CUTS was born lol

And here we are today. Full circle. Stop.

Also…looking back at the thread…

Was the user that made the mistake of cutting PVC on their first job…

That may be the owner you’re thinking of…