I am working on creating a version of the hokule`a, which has been fun, but I Am having trouble making the the best living hinge that won’t break when I bring the edges together…

Any ideas?

I am working on creating a version of the hokule`a, which has been fun, but I Am having trouble making the the best living hinge that won’t break when I bring the edges together…

Any ideas?

As I can see the design, they are too far apart of each other and there won’t be enough wood to be bending without breaking it! (I think).

Maybe if you create longer and more flexible, maybe leave only the end bits without the bendable cuts! ?

Looks really nice anyway!

Get the wood very wet before bending and let it dry still bent and it will stay that way. I often let it soak in a plastic bag for 24 hours at least to get the water even everywhere.

Very cool looking little water craft!

In addition to extending the cuts and dampening them, I would orient the cuts vertically on the wood to relieve the stress in the correct direction…they look great slanted, but that isn’t where the pressure is being applied, and the force won’t distribute evenly if they are slanted.

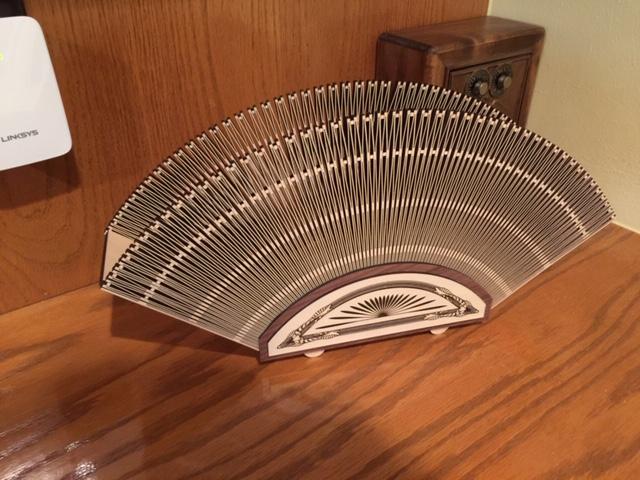

Remember this thing? That is just a straight up and down perpendicular hinge cut on a scrap rectangle. If the cut crosses over the edge, it fans and bends very nicely. So all the cuts have to cross the edge as well.

I will give it a go! Mahalo!

That looks amazing! when I’m done with my string of overnight shifts I will realign the cuts and submerge the boat!

By coincidence I was working on living hinges this morning with my son.

On this part, which is 9cm x 3cm, the living hinge worked best with just a single large slot as opposed to multiple like you’ve got. The slots are 1mm wide, spaced 1mm apart.

This hinge easily flexes past 90 degrees, and is planned to be part of a box with curved corners.

The code that generates this (a little messy, sorry) is below, and you can paste it into openjscad if you want to try generating different options (different slot widths, different numbers of slots, different size rectangles, etc). The material I am using is the maple proofgrade.

// openjscad.org code cut and paste below

function rect(w, h) {

return CAG.rectangle({corner1: [0, 0], corner2: [w, h]});

}

function living_hinge(w, h, slotHeight, numSlots) {

var sh = slotHeight || 1.0;

var ns = numSlots || 1;

var sw = w / ns;

var gapWidth = sw / 5;

var slotRatio = 2;

var nr = h / (sh*slotRatio);

var slot = rect(sw - gapWidth, sh);

var empty = slot.subtract(slot);

var ret = empty;

for (var sr = 0; sr < nr; ++sr) {

var row = empty;

for (var si = 0; si < ns+1; ++si) {

row = row.union(rect(sw - gapWidth, sh).translate([sw*si + 0.5*gapWidth, sh*sr*slotRatio]));

}

ret = ret.union(row.translate([-sr%2*sw/2, 0]));

}

return ret;

}

function main() {

var w = 20;

var h = 90;

var slot = h/3;

return rect(w, h).subtract(living_hinge(w, slot).translate([0, slot]));

// switch to this if you mess up where the hinge cutouts are, to see the subtracted rects

// return living_hinge(100, 50);

}

A couple of points, the first is that whenever stress is applied it is sharpest at places of rapid change of shape such that when there is a sharp point that will nearly always be the point of breakage. A neat trick is to make your test in clear acrylic and have two sheets of polarizing film set up at the angle of least transmission and with strongly polarized light between, bend the various pieces of Acrylic and watch all the pretty colors. You get rainbows wherever there is stress and the more stress the tighter the rainbows. I think you will find that the stress is greatest at those hard angles. If you try that same trick here I believe the rainbows would be much more even.

That’s neat! I will give it a try