Like many of you, I like to mull beautiful laser cut project photos for ideas after my GF arrives. Obviously with smoke and under flash protection burn damage can be better contained, but I’ve noticed a bunch of pictures where the edges don’t carry the usual dark burn. Are these projects where that is usually sanded away in after finishing? Or is this more controlled through speed/power (or air assist) at the cutting stage? And if it is sanding, how deep does the burn tend to be?

Looks like cleaning off the soot on the edges is fairly simple:

You can also mask it, and that completely eliminates the oxidization residue on the edges. (Bought a roll of this paper tape.)

https://www.signwarehouse.com/c/perfectear-plus---medium-tack

Are you talking about the staining on the surface of the wood, or on the cut edge itself?

The surface can be masked to eliminate any smoke staining or damage. The cut edge is always going to show some burn, although it varies in depth based upon the speed/power settings you use. The only way I know of to remove it is by mechanical means after cutting.

Wouldn’t a higher speed result in less charring? A systematic removal of a little at a time instead of blazing through it in a single pass?

@jkopel, I am speaking about the cut edge burn. I have read about different masking/coating materials and tray arrangements that can be used to help control the upper/lower fascia damage. So I presumed sanding may be the only option, but interested to learn from @cleetose that pumice soap may possibly be an option.

I’ve sorta been wanting to broach this subject as well. I see a lot of photos on this site and elsewhere that show cut edges that are jet black (charred). Are people making a conscious effort to make the edges charred? I could see how that aesthetic could be desirable for some projects. Or are charred edges an unavoidable byproduct of the laser somehow?

Here’s a video I recorded (mute the audio if you don’t care about what I’m talking about) that shows some ~1/8" baltic birch immediately after being cut. There IS some discoloration, but it’s far from being charred. I should mention that the laser that I used is a Trotec brand, not a Glowforge.

@Hirudin yes that is exactly my point! I don’t mind a “caramel” edge like you are showing but the black “soot” concerns me. I like its contrast aesthetic some times, like on that iPhone holder project shown on the GF home page. But generally I don’t like it so charred.

That is probably a mixture of material types and settings. MDF most likely doesn’t cut as clean.

Probably four main things will affect the shade/amount of edge charring. Speed, power, material and air assist. Material definately has a lot of effect - some MDF I’ve tried chars more than it “cuts”. Unfortunatley the stock K40 I have makes it hard to play too much with power and speed ( at least for much replicatable (if that’s a word) use). Proofgrade should help

I had assumed that the black edge was just how things go. But when Codex Silenda got their technician out to configure the laser, they posted an update showing that they can now cut without the char.

So, there is certainly a way to minimize char. I have not really tried to figure out what that is yet. But I would imagine cutting faster is not the only thing possible, as I was already cutting at maximum power and had to run multiple passes to cut all the way through.

I’m curious about this same issue with paper–I could swear I’ve seen laser cut paper projects that seem to have no char. Am I missing something?

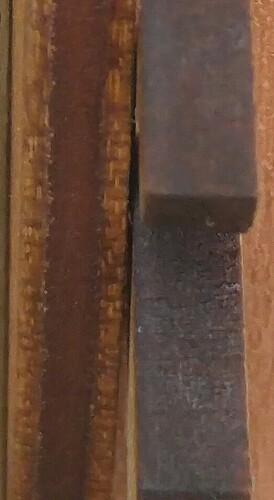

As stated, it depends on material. Baltic birch ply gives a carmalize look ( left), however the MDF burns darker.(right)

Paper is so thin it may not have time to char…

depends on the type of wood, how it was cured, power and speed, etc.

I really appreciate all the input on char causes and variability between settings and materials. Any feedback from someone who knows how deep the char tends to go? Is it very surface level? (It seems that way to me from looking at a number of projects). Downside, except for the pumice soap suggestion, char removal doesn’t look like an enjoyable job unless working in cut designs that don’t have a lot a fine surface detail to the edges.

One of my reasons for caring is that I want to make some kinetic wall sculptures—and will likely start with some pre-designed plans (eg Derekhugger.com) till I get a better sense of the processes. Seems that sanding these shouldn’t be any worse (and likely better) than hand cut pieces for achieving the final balance and aesthetic goals.

It’s pretty shallow - half a mm maybe. But like you noted it’s a bear to sand off if you’ve got a lot of intricate details.

For non-colored edges you need to go CNC or an alternate material like acrylic.

If you have a router and plan to go through and contour the edges anyway, it is a non-issue. But if you planned to have the piece on display, with the edges exposed, then it is indeed a nuisance to clean up. Even with mostly rectangular items I get sick of it.

In the fractal puzzles I made, while working the pieces loose from one another I would shower down a whole lot of soot on the tabletop. I did not bother attempting to clean those, as it would have made for a loose fit to the whole puzzle.

Yes, this - we choose our Proofgrade materials in part to give a nice edge look. For example, the edges of natural walnut turns black, but isn’t significantly sooty (that is, it doesn’t rub off).

when i cut wood i will give it two coats of shellac and i can just wipe away and smoke or soot stains that occur. i have found that sometimes the masking tape does not hold while it is being cut by the laser.