I have heard that the glowforge can cut fondant. Can it cut soft leather hard clay for slab work? Hope so. Would someone be willing to try?

I’ll be in the lab tomorrow. I’ll see what I can do.

I floated it past the bosses. There are question marks around moisture content and amounts of steam. Also whether fondant has an edge in being organic material and therefor something that can burn.

… We can etch stone, right?

Maybe mineral just means we can’t cut all the way through?

Yes, I suspect the intersection of stone and water is not going to work well.

It could only be a horrible mistake, right?

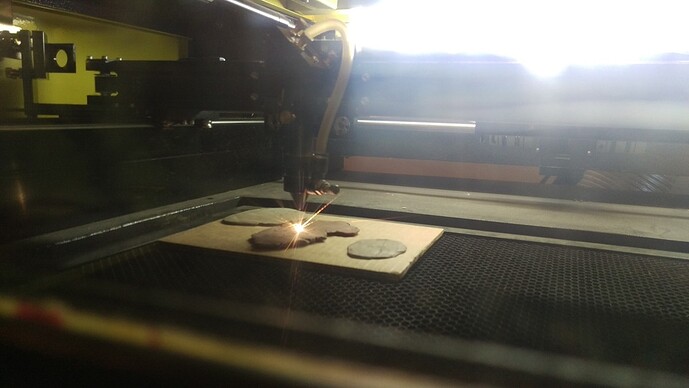

Ok, that was fascinating.

I found 2 kinds of mineral clay in our bin, red and grey… I used to know what they were called, but whatever.

I didn’t bother letting them go leather hard, but I did spread the clay out on cardboard.

Holy wow!! The clay crystallized!

The kids pointed out that it’s like the laser fired the clay.

It tears so easy, what will 2 passes do?

Two passes, deeper haloes around the cuts.

The bottom shows it still didn’t go all the way through, but the tear apart got easier.

I’m calling this experiment awesome. What will you make?

That is pretty wild. Not the result I would have guessed, but does make sense.

I wonder how that would look if you did a single pass to create your design and then fired. Looks pretty unique and might net a nice result. I have a kiln, something I will play with for sure!

Thanks for taking the time to experiment!

Thanks all. One of the reasons I suggested leather hard because there is less moisture. The tests look really interesting. Do you think doing this in the Glowforge would hut the machine?

With the wet clay, the laser edge crystalized. Did the rest of the clay remain maleable? Do you think it could be shaped into a cylinder or only flat slabs?

This is really cool! And I have no idea if it would hurt the machine I’m afraid.

That is really funky looking and awesome. What does the laser do to fired clay anyway?

Of course I have no idea if your Glowforge (or your lungs) will be safe if you choose to pursue these experiments. I’ve also never been warned of any toxic chlorine type fumes from pottery kilns… my shrug is enormous. You might start googling around clay ingredients?

I do think leather hard is a good idea, I just didn’t have time.

Yes! The rest of the clay was completely the same as it went in, other than the seemingly temporary discoloration? Again, I was quick and sloppy with this trial.

I think it would be very possible to get some neat results from shaping the lasered clay… I don’t know if our 'forges will allow for rotational burning… (guys?) but Zuko has a setting for spinning the material. (We’ve been pondering cutting a design into a rolling pin.)

Doesn’t it just etch away some of the material?

I am very curious to see what will come of engraving onto raku fired clay blanks, both with glaze and without. The unglazed raku is blackened on the outside, but remains white on the inside (according to a ceramicist friend who is making me raku flatware as we speak) so I’m imagining the potential for an interesting effect.

You could technically 3d print something with this method…

You’d have to figure out how to make the gravel bind to itself.

I love the idea of the engraved rolling pins but aren’ they too wide for the forge?

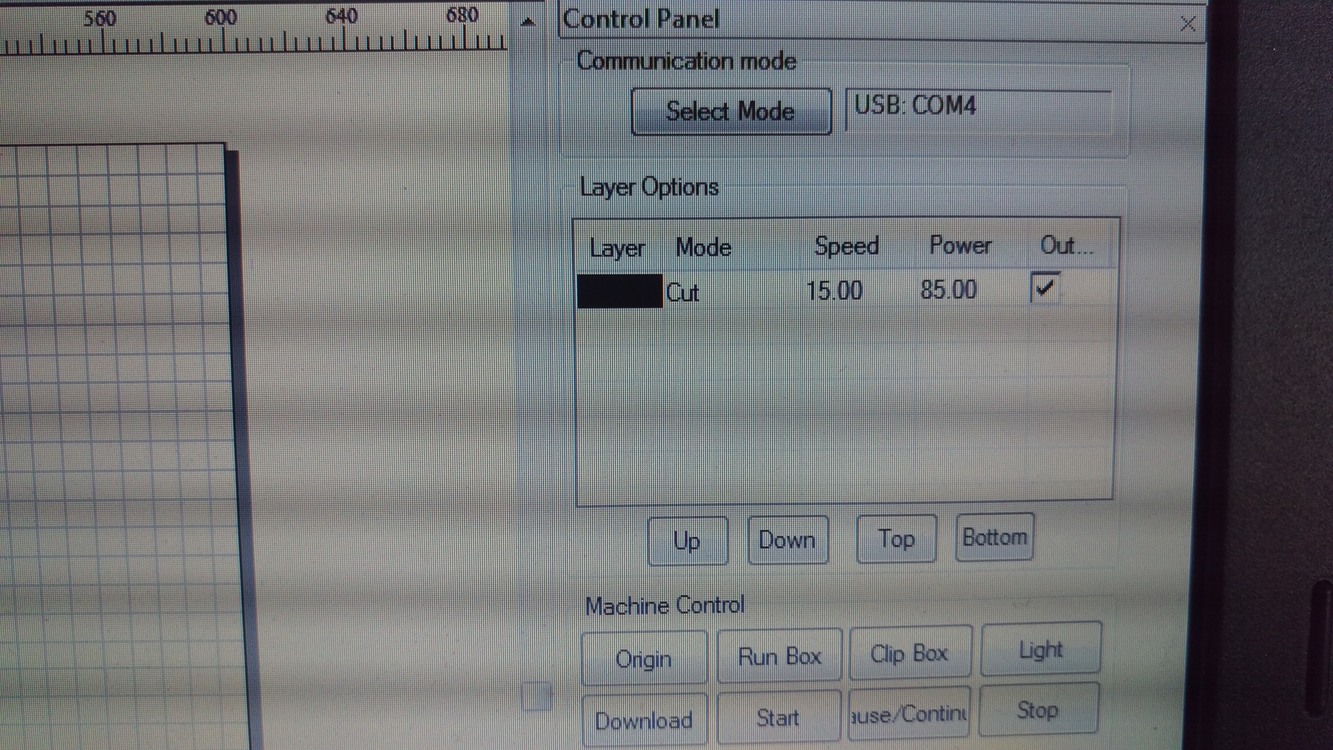

Yeah, Zuko, my lab laser cutter, is bigger than the 'forges will be.

You actually can engrave and cut patterns on thin, flat slats of material and glue them up onto a roller for the circumference of a bigger roller. So using the foam or rubber for the stamps and then glue up to the roller. I could imagine even using delrin or acrylic and heating up to curve over the roller for a crisper indent. Just thinking on paper here. Anyone out there do this?

would love to see this , especially the acrylic, How would you heat to bend?