An MX? That would be very surprising given they just came out… There is an upgrade kit to make a 770 into a MX (servo conversion kit)

No the older stepper model I think - the new servo based model may be driving upgrade replacements. Or going to the 1100 models maybe.

All of them are way more than I really need or could find a use for but doesn’t stop me from looking. Plus I need to build a new shop because no way am I gonna get anything that size in & back out of the basement and no way am I gifting that to the next buyers of the house ![]()

Of possible interest relating to the ventilator DIY stuff:

(i.e., getting a better understanding of how much you don’t know.)

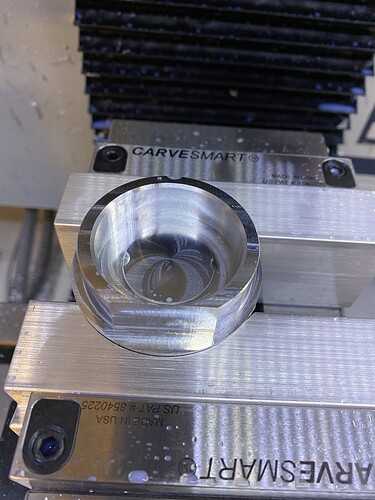

Getting some good milling in today (these are op2 on my softjaws to do op 2 on my part). There are actually 3 ops on this one set of carvesmart soft jaws.

You are having too much fun!

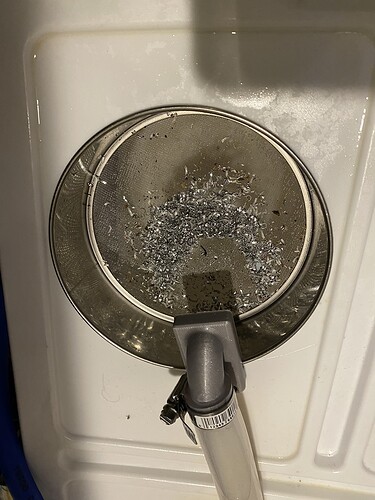

I have a rig I built based on some you tubers I follow with a flour sifter. Works really well. Those are the chips that got through Easy to dump those in my chip recycling bucket. :

I started using the green 3M pad in the metal CNC after I got my plasma. I get slag and molten metal droplets that fall in the water tray under the cuts. There’s also metal “dust” that is produced. I empty the tray everytime I use it into its own storage tank & the fine particulates settle out. The water gets pumped back into the water table (about 16 gal on the new table). After I put the 3M pads on the drain it cut the particulate that settled by more than half. On the metal CNC it cut out all the chips I used to have to chase. The pads come in 3 or 4 different coarseness levels and I have some of the gray (sold for fine sanding) when my green ones are all used up. Going to see if the gray (or brown) ones still let it drain sufficiently fast.

The advantage of the sifter is I can easily put the errant chips into recycling. Sometimes I just wash the chips down as it’s easier than picking them up

I decdied today to start using electronic probing instead of the Haimer probe. It’s pretty cool to watch it automatically find the center.

You are doing some advanced stuff!

But how is the pump going to seal without all those chips passing though it?

When I first started doing metal I was going to save bits & recycle them…that lasted about an hour ![]() Now I just vacuum it up and toss it in the trash. I’m one of those people.

Now I just vacuum it up and toss it in the trash. I’m one of those people.

Aluminum is so recyclable I’d feel guilty just tossing tens of pounds of it…

It’s not a problem for the pump. The pump is a submersible sump pump, so can handle up to 1/4” debris. The problem with chips is they clog the coolant nozzles in the mill and of course blowing metal chips onto your work piece is essentially sand-blasting. And one key purpose of coolant is to blow chips out of the cutting path so you don’t re-weld chips…

That probe video is really cool! It looks like it estimates the location of the four tangent points based on measuring the radius?

You’re a real inspiration.

It has a square and circular boss mode (and for circular there is rough and milled, in this case since that was stock, I selected rough), it has the reverse for pockets (I.e do this operation from the inside), along with the usual corner probing function (you can select the corner). There is basic measurement (don’t change the WCS) and then just measure this thing (use your mill as a set of calipers)

not as messy if you collect it in your shoes though:)

I guess my joke was not funny…

This topic was automatically closed 32 days after the last reply. New replies are no longer allowed.