Ok, so I have gone ahead and built myself a new RepRap 3D printer and am loving it a lot. Then I remembered that there was talk in an ancient time on an unknown planet of these crazy things called… ACCESSORIES!!! And rumor has it that there was and possibly still are plans for things like 3d Print enabling accessories in place of the glowforge head, can this be confirmed? (Just so that it is noted, I am not trying to be mean with how that was all worded, I just was bored and felt like bringing lore into the conversation.) Also being the amazingly over thinker that I am I must admit that I actually designed an amazingly over dreamed 3D Print “Accessory” myself for this and a part of me wants to make this a reality. Biggest issue I have is clearly the simple fact that the GFUI most definitely does not support this. Now a solution would be a modded firmware and my friend believes that he could do this for me (and I do to, he is amazingly smart, he had me custom 3d printer printing less than an hr after the last screw went in. I was wondering if there are resources for 1. the firmware for a Glowforge Pro, 2. Any documentation that would not be too much to ask for like maybe pinouts of the MAG head connector and wiring diagrams that let us know a bit more about the machine without tearing it apart and getting DUMPS of the boards (witch I am more than not ok with tearing my machine apart.) Any information or insight would be amazing.

You might find some end-user generated documentation here:

Glowforge still hasn’t delivered many of the core features promised when it first went on sale, so the chances of you getting a kit to convert it into a 3D are basically zero.

Beyond that, it’s actually a terrible platform for a 3D printer IMO.

I can 100% verify that the rumor exists!

There isn’t room to do that on the current GF. The hot-end is at least an inch tall, then you have to have a Z-axis rail, motor and filament feed, you could set up a Bowden feed and put the motor by the coolant tank since there’s some room there. All that aside, there isn’t space for filament inside, and no external access points. The Z axis would be limited to about half an inch after all that gets stacked in there. The other option is a moveable bed, but there’s only about 2.5" between the case bottom and the head mount. That doesn’t leave much Z axis when you have a base, rail and bed to squeeze in.

I’d think pens, blades, diamond points, etc… would be more practical as accessories with the current platform. That shouldn’t be too difficult to design, then you’d have a very expensive Silhouette. Put me down for a blade attachment, would love to be able to cut vinyl.

You can get decent 3d printers for $200 now, I’m doubtful GF will spend R&D to develop a 3d print attachment.

Another fun option would be another axis to etch round objects, but again, space/focus is limited to 2", but pens, golf balls, eggs, etc… could work. Unfortunately, I believe the internal USB port was removed on later boards so there’s no way to attach something like that. Maybe an enterprising individual could build a rechargeable, wi-fi module, hack the GF connection/security and sync the axis with the laser head…hmmm, would be a fun challenge.

I’d like a plate marker so I could take advantage of my laser designs in steel or other metals

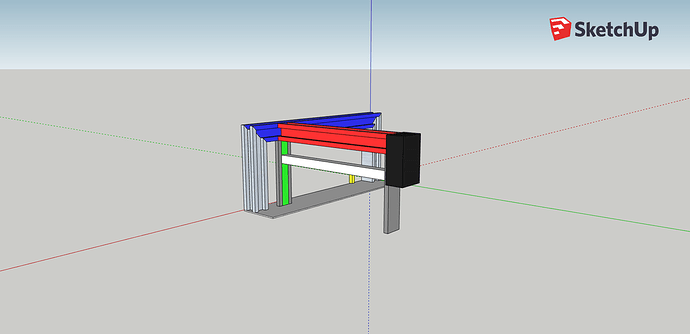

so I had some ideas to compensate and here is a rough idea that I had sketched

so the red rail would move along the blue with bearings of sorts, the blue part and its frame would stand at the front of the machine and there would be little dimples on the bottom of the plate to sit in the foot notches, the white part carrying the nozzle (the yellow part is the nozzle) moves along the green with linear rails, and the black box is in place of the head and houses the control board and a motor to drive the green axis. the heated bed would be way thinner than the crumb tray, and sence I have a pro I can power the bed externally and feed the filament in throught the front or back. as well as I could do abs cause the gf is closed and would hold heat well.not in any way am I saying that this is a better investment than an actual 3d printer but it would make a cool project. (bonus points if I can make it go in in two pieces, to make install easy.