The ironic thing is if it is happy to head bang on the left it could simply move left 20" and then right 10" (or whatever the exact measurements are) and be bang under the head.

Yeah, I know you have a quick and easy solution.

Some 3D printers actually use that method to home X and Y although I wouldn’t advocate it.

Since the current is programmable it could do it gently. Just drop the current and slowly drive left. Since it parks back left it can bump off the end stops very quickly and then zoom to under the head for fine registration with the camera.

With the accelerometers in the head it could even detect the bump and stop without grinding

With modern computer vision it would be easy to locate the head logo unless the camera is dazzled by something.

So I really don’t know why after two years of development it can’t home reliably and why when there are daily reports of it they don’t roll out a fix post-haste.

ding ding ding…back to your corner now.

Mine has done this so consistently that I’m wired on moving the head every time. I initially read the others posts about moving it below the camera, but I’ve found moving it even just a couple of inches to the right is enough to fix the issue.

To clarify, this is only ever the case when the machine has been off and I turn it back on, but I have never experienced the issue if I do more than one print in a session.

OK. I spent some time trying to figure out why so many people are having problems with the head bumping into the left stops. My machine does not normally have this issue but I was able to reproduce the problem. I power cycled my machine and moved the head to maybe 50 different positions for calibration tests. The following is speculation on my part but seems to give consistent results.

Edit: I had to edit the rest of this post because I’ve done additional tests. Hope it doesn’t confuse the topic flow

It seems that when the head scrapes down the side of the machine during calibration it is because the S/W has lost track of the head. When the S/W gets confused the head could be driven into hard stops on the gantry. (stepper motor assembly) Can only speculate as to the cause. The camera might not be able to see the head clearly or maybe cutouts in the material on the bed may confuse the camera. Might not be one reason. Either way, the solution seems to be to move the head to a position where the camera can easily recognize the head before power on and calibration.

I had originally thought that the camera alignment accuracy could be part of the problem. Now I don’t think so but can’t rule it out.

That has been my experience, too.

Finally an explanation, thanks. I wonder why it wants to move left 1/2" before it can see where it is.

Has to be a reason but can’t think what it might be.

I think you might be on to something.

On this PRU, the place where the head gets parked after a print is normally about half an inch to the right of the stop. I also think that’s the natural home position for it.

The only time I’ve had the whacky-whacky happen is when I have accidentally moved the head all the way to the left against the stop. I think it’s just expecting to start about half an inch further over to the right. (I move it during cleaning, or if I have to stop a print for any reason.)

The whacky-whacky will continue though until the whole shebang gets reset by turning off the machine, centering the head under the lid camera, and letting it reset itself once. After that, I can turn off the machine normally, and it starts itself back up properly over on the left side of the bed.

Like I said, I don’t see it often, but I also don’t move the head by hand, even with the machine turned off. If I just don’t mess with it, it’s not usually a problem for me.

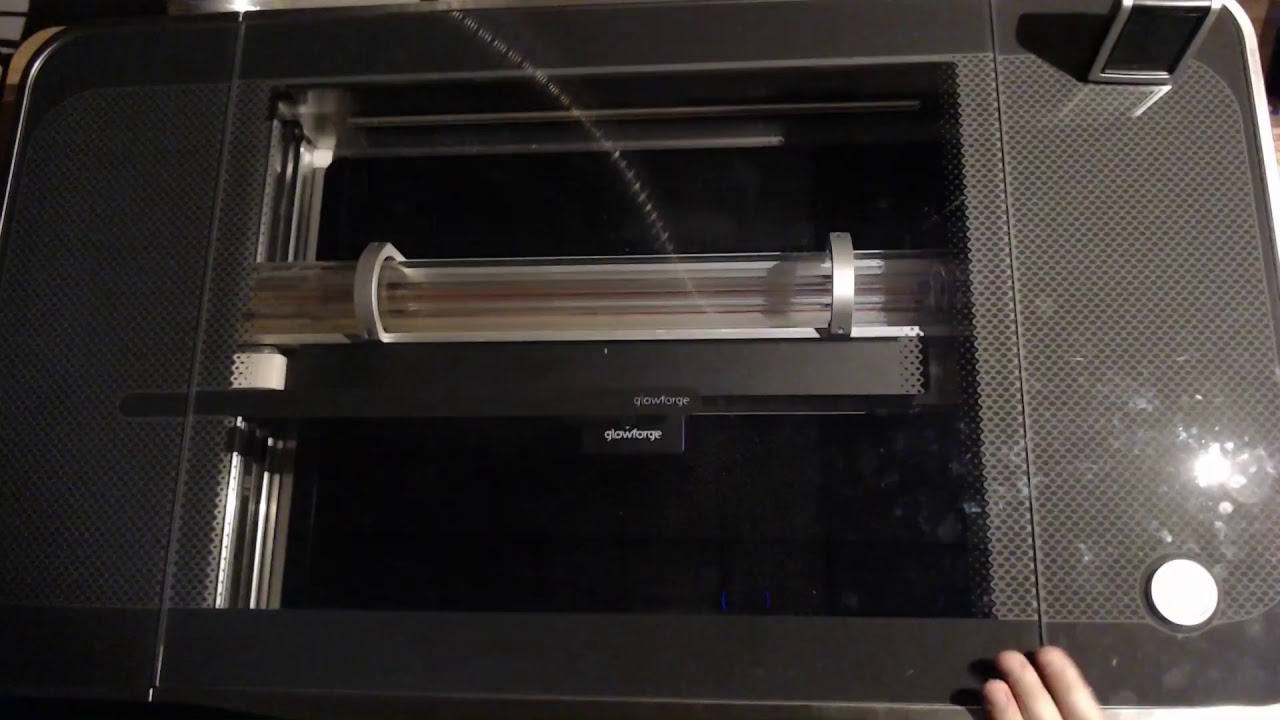

Ok, folks. I’m posting what I’m going to call the definitive recording of the Glowforge startup and homing procedure. Including a variety of tests which may debunk some of the theories posed earlier in this and other topics. I didn’t go into this expecting to prove anything, but I think the evidence suggests that my earlier guess is still the most plausible.

I’m very curious why rpegg’s machine apparently does an initial move down and to the left, when mine moves toward the center on both axes.

Anyway, it’s all here for the record. Pixels don’t lie:

Everything you showed mine does also. It doesn’t always move straight down the left side. Mine does both motion paths. The one where it moves directly toward the head camera and the one where it moves almost in a straight line down the left side but also moves toward the left stops. The one that moves toward the center never scrapes. The one I described always scrapes. Don’t know why it takes one path or the other. Might be light interference, the lid camera might see the head but be confused by cutouts in used material. It clearly has lost track of the head. Doesn’t matter to my description. When it scrapes down the left side it is hitting the stop on the gantry motor assembly which creates the sound everyone is complaining about. I can also give you a setup where it will always hit hard stops on the right side. Nothing I said conflicts with your video or your earlier statements.

BTW: you can feel the ticking noise you described in the head so doubt it is the pump.

That’s how they light the laser. ![]()

ROFL! The clicking sound is part of the normal startup calibration sequence. (Rita’s mentioned it a couple of times now.)

(Although, have to admit, it would be more fun if it was a firestarter.)

You missed testing when people try turning on the Glowforge with material sitting in the hopper, and allowing it to try aligning.

In fact, I’d like to see a piece of light colored material sitting in there (like maple), with a box cut to the rough dimensions of the head assembly, and then see the startup procedure take place.

If you put the cut hole in the left-hand front half of the hopper, but leave the head in the back/left park position, I suspect that’s when you’ll get your head crashing into the back side and moving right. Because I think the dark hole will trick the initial calibration move into thinking it needs to move backwards/right to make the head visible for the successive centering moves.

Which brings me to another question about people reporting head crashes against the side: are people leaving material in the hopper when they try rehoming?

The ticking from the head at the start will be the homing of the focus stepper motor.

I wonder if there is half an inch difference in the lid camera view at the extremes between machines, so some people’s machines can’t see the head when it is parked and that is why they don’t home reliably.

@chris1’s your video looks like your machine copes with any starting condition but you also mentioned it occasionally head bangs. Can you remember what was different? Did you have material on the bed? Do you have bright lights or sunlight shining on it?

I have to go by memory, unfortunately, so this isn’t very reliable. But as I recall, it has happened a few (3-5) times, some of them with material on the bed (because I know I’ve removed it for the second try). I can’t say for sure that it has happened with an empty bed and no extraneous light, but I think it has. In any case, it’s not repeatable for me. Most of the time it works just fine, even with stuff on the bed and all the lights in the lab on.

Vaguely related anecdote: I have a very complicated toaster that also has a camera inside and unnecessary machine vision features. About 40% of the time, it is unable to correctly count bread slices. I’ll put in two pieces and it’ll say 6, or 3. Or it fails to detect the bread at all. I think we have a ways to go yet.

I’m now curious, too, since mine differs from yours as well! Mine goes down to left-center, then straight right to under the camera. I’ve gotten the headbang (down/left) a couple of times. But typically, it’s a straight shot down, then a straight shot right.

That said, I didn’t watch that action over the weekend, so it’s possible that motion has changed since the last time I watched.

Funny if they fixed it just before @chris1 made his video.

I don’t know why they can just say what goes wrong when it headbangs and why they can’t fix it easily.

As I said I get both types of motions. For a long while only the move to center under camera was the standard move. But it changes back and forth. When I was testing yesterday and it was consistently moving down the left side, I did have material on the bed with head sized holes in it. It is quite possible that the lid camera was confused as to where the head was. Maybe the 1/2" travel to the left could have been an attempt at a 5" travel to the left if the camera thought the material was further to the right. Again this is all speculation based on one machine. If I get bored I might play with it some more . If the results change I will edit my post above.