Yeah, I will have to check with my accountant. But, it seems that if I am providing a product, the cost I would ordinarily charge for that product would be a write-off, I would think.

it wouldn’t look the same as laser-etching, but that design would lend itself pretty well to a woodblock or linoleum print (linocut).

Were you going to personalize it at all (names) or just the tree?

Just the tree, James. No personalization. The tree design was chosen by the kids. It’s done by a local artist.

It took me a bit (college dropoffs, business trip) but I was able to get some chipboard from Blick and try that file you had.

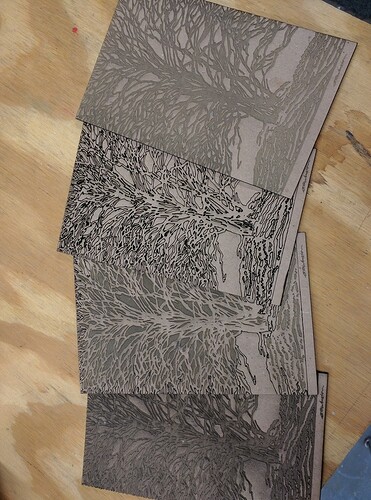

Interesting project. My first cut was opposite what I wanted (engrave the black). My laser software won’t import PDFs so I had to open it in Corel and export to DXF. I opened the DXF file in my laser software and sent it to the laser. The first sample (bottom) in the picture resulted. Corel translated the blacks into separate objects. One of those was the bottom black section which was engraved but the other objects were not engraved, rather the spaces around them were engraved. That was because the bottom strip combined with some side black sections and formed an engulfing object. Since the laser engraved between black lines it flipped the raised vs engraved objects.

So I changed that bottom (and the engulfing objects) to a low power, high speed cut to get a score instead of a cut or engrave. That’s the second sample. Pretty neat effect. That one took 22 minutes ![]()

The third sample was a full score without engraving. All vector based. A really neat effect. Not sure if I like it better as outlines or with the various parts of the tree cut out showing what’s underneath. That one took a bit over 26 minutes running at 500mm/s @65% power. There were some cut outs so if I did it again I’d drop the power to 45% ( it’s a 60W laser).

The last sample (top piece in the photo) was exported as a bmp instead of DXF and then raster engraved. The black parts of the drawing were deep engraved. I ran that one at 750mm/s @65% power and took 15m30s. I expect I could match your guy’s 12m engraves if I boosted the speed to 1,000mm/s.

So, 12,000 minutes or 200 hours to do your book covers. Lasering them doesn’t look like a good option. At least not with lasers that can’t go faster. An ink or silk screened print looks to be your best bet.

I’d think that silkscreening would be perfect for this. The time and cost per unit is near-zero, if you can get volunteers to do the work. And it’s easy enough that the kids could do the silk screening, which would be a lot of fun. You can get a good one-color silk screening station for $250 or so (i.e. not just the frame but a base to hold the object you’re screening onto, a hinge and arm to hold the screen out of the way, etc. For example - https://store.schoolspecialty.com/OA_HTML/ibeCCtpItmDspRte.jsp?minisite=10206&item=526858&gclid=CJGzpPnh2s8CFVZbhgodiN8C2A .

Laser etching would only make sense if they were individualized - you wouldn’t want to make 1000 silk screens and use each one once!

Concerning a tax write off, on the Federal end of things you can not write off services rendered or time donated, only product actually give (or money, of course). You could buy the material, laser it and donate it, but only for the reasonable value of the finished product, you couldn’t not actually count time on the laser, or any of your time as part of the value of the donation. If you ended up being audited and got a jerk for an agent, they may simply let you count the cost of the wood. Being in full time ministry (non-profit) we run into this a lot.

Thank you so much Kenneth!