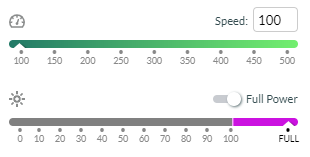

Got my glowforge this morning. Opened it up and followed all the steps. Ran the gift of good measure and it engraved fine but didn’t cut through the medium draft board. Like at all not a mark in the back. Talked through chat to support and followed their recommendations on cleaning and resetting. After that I can’t get it to engrave at all. The laser moves back and forth but isn’t firing. Even on full power and 25 lower speed it does not come close to cutting through.

Any help? Or ideas?

I’m in Alaska so I’m dreading the 2 weeks or more (took 4 weeks to get my pro here) it’s going to take to replace it and the time difference is killer with the chat support. Looking for anything that could help. Thanks!

Did the support chat include checking to make sure the lens is the correct side up in the head? An upside down lens could cause those symptoms.

The correct orientation of the lens is discussed in this link:

You can’t go any slower than 100 so your full power and 25 speed comment is misleading. Looks like the material was not flat. It doesn’t take much. If you can press on it and feel ANY movement it is not flat. Usually slowing the speed down by 10 will allow PG to cut through.

Make sure your optic path is clear. Very important to make sure the two windows (left side of the head and left side under the gantry) are clean. It is easy to get finger prints on the one on the head which will cause problems.

My experience is that there’s “flat” then there’s FLAT . A very common gotcha is that even a visually undetectable warping of the material can cause issues. If you tap anywhere on your material and hear a click or an hollow sound, it’s not FLAT .

Your best bet is to cut out a dozen or so Honeycomb Bed Holddown Pins and use them to make absolutely sure your material is firmly secured. I cut out a few from draftboard scraps leftover from various jobs – you cannot have too many of these. ![]() You can also use either ferrous or neodymium magnets to hold materials flat, but be careful to either shield their tops or place them out of the path of laser head – strong magnetic fields can slow the air assist fan, causing the print to be aborted.

You can also use either ferrous or neodymium magnets to hold materials flat, but be careful to either shield their tops or place them out of the path of laser head – strong magnetic fields can slow the air assist fan, causing the print to be aborted.

My cutting success skyrocketed when I adopted these as part of my workflow.

Yup!

Best of luck!

Yes I checked this like 4 times. Mainly because I figured I had to be missing something stupid and little. It’s sitting like s bowl in top of the blue remove and then inserted.

Sorry it should of said slowed down by 25 not to 25  I’ll change it in the post.

I’ll change it in the post.

And yes I’ve cleaned the optic paths and checked them all. This is the 3rd piece of draft board I’ve tried cutting on. I even taped one down because someone else said it’s probably a warp. But I tap on them and feel nothing moving or bouncing.

I have the pins file saved to cut and I actually attempted to cut one yesterday on 2 different pieces of material one not being proofgrade and I couldn’t even get the laser to make a mark.

I did place a small piece down with duct tape and it didn’t help either.

I just feel like all 6 pieces of wood can’t be warped but I’ll make sure to make a lot of pins to use in the future when I have a laser to do it with

I see you already emailed us about this and we’re working on it there, so I’m going to close this topic.