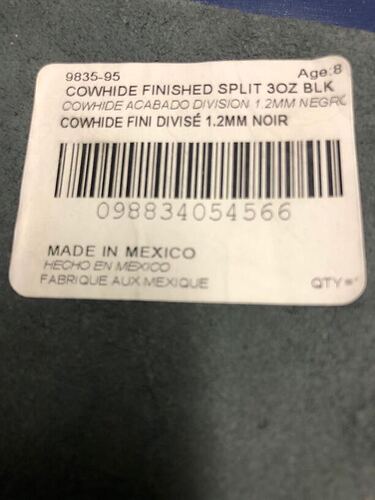

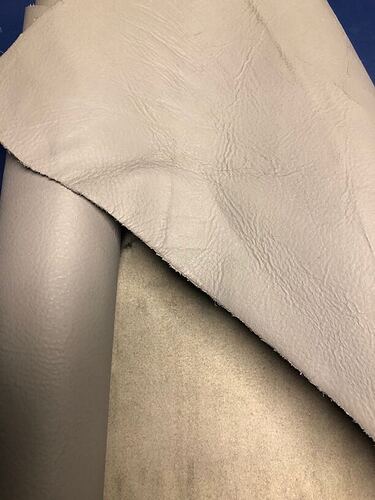

New to purchasing leather and working with this material on the glowforge. Purchased 2 hides from Tandy Leather (see photos). The black hide is finished and 3oz. Having issues trying to find the best manual settings for Speed and Power to make clean cuts. Using the leather to make some card holder wallets. Any suggestions? Also, any issues with safety regarding chemicals etc to worry about when buying finished hides and using the laser?Thanks for your input since I am a total newbie!!

Work with only veg tanned leather, never chrome tanned.

measure the thickness at several places on the piece you’re working with using a digital calipers - don’t rely on the weight on the label. If it’s not cutting through, slow the cut speed, increase the power, or run 2 passes. If you have the thickness right, choose the ‘proof grade’ that is closest, then convert to a manual cut. if the leather is thicker than the proof grade setting, slow the cut speed down. if it is thinner, speed it up. and if you’re worried about marking, mask it.

Plan to test a lot. Also get lots of magnets to hold the leather flat on the bed–even if you have the right height setting, if the material isn’t laying flat, it won’t cut cleanly.

The GF proofgrade “thick” is actually fairly thin leather–about 5 oz, and you may get decent cut using that setting w/ the marked 3oz leather, but a snap gage is the best way to confirm thickness–but some hides are also rolled/compressed for thickness, which changes the density, and thus how it cuts can vary across the hide & setting many not work for another hide that is same thickness, but different type of finishing.

And you can get chrome tanned leather that is OK for laser cutting/etching–but it may not be what you have bought.

But I don’t buy leather at Tandy, but it’s a way to start, esp. if there isn’t another leather shop near you, but as you get more familiar with terms & what works for your projects, lots of good sources you can order from.

You also need to understand the “temper”, or firmness of the leather for the type of project you’re doing so you will get a result you’re happy with.

So far I continue to hand cut my leathers (mainly w/ my rotary blade) and etch on the GF. I also machine sew, so a little bit different considerations than hand sewing, too.

Not that I have a lot of experience, but I did find elsewhere on the forum that people were using 200 speed and full power. It worked for me, mostly, but like others have said hides aren’t the same thickness all across and some parts seem to be more dense. I was using veg tanned so that may also make a difference? I’m guessing that my leather was thicker than yours - I used .18 as my focus.