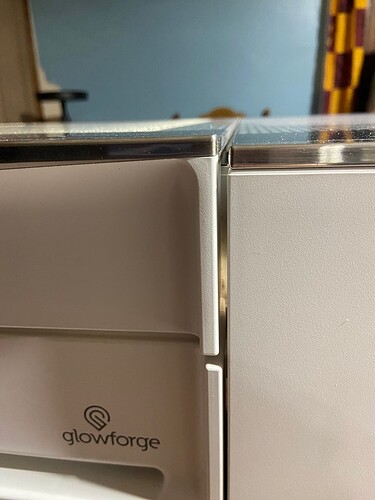

Since I got my glowforge I’ve noticed the glass lid on one side is lifted, like it’s off angle. Anyone else have this problem? If we don’t put something on it to hold it down during use it blows dust and the smell out that hole while being used. Is there anyway to adjust this? It’s the pro model.

A picture would be helpful. There is flex built int the Glowforge body. Gently lift each corner and return to the table. Make sure your table is level and that the Glowforge is level. If not, shim the offending corner with a couple of index cards until all of the lid sits flat.

Yup, it’s pretty much a certainty that the surface it’s on is not flat.

Shim as explained above.

You can shim one corner with a few sheets of paper or something. To determine where to shim it, slightly lift on one corner and observe the lid clearance. One of them will correct for the flex.

I will get a picture later today. And I will try the shimming. The Glowforge and table are level, so I know that isn’t the problem. It has been like this since I opened the box.

It may not be your problem. Still, it’s important to know that level is generally not an issue. The GF needs a perfectly flat surface (not the same as level) and honestly it needs a far better flat than my eyes can discern. An off flatness of only a few pieces of paper thick are visibly enough to raise one side of the lid higher than the other.

Also, please note that on most if not all machines the center lid glass does not sit flat across the top. Your goal is to get the front left and right side of the lid equal and closing easily without scraping.

Exactly. Level and flat are different. If the surface isn’t flat, the lid will be offset.

Sorry I meant flat. The surface can’t get any flatter. We even got a board on top of the table that is as smooth as can be to try that. Still the right side is lifted about 1/8” inch and has to be held down to keep anything from coming out. I’ll try paper under it and see if that helps any. The machine operates without any problems, it’s the the gap at the glass lid letting the smell escape.

Can’t think of anything else that would cause that type of gap. Guess it’s possible the lid wasn’t installed properly or the adhesive let go. Either way, when you say the smell escapes, does that mean while the unit is running or after it has completed an operation? The exhaust fan is more powerful than the intake fans. Any smoke or smell should be kept in the unit or exhaused as air is sucked in through cracks while operating, not out. After the exhaust fan stops residual smell can escape.

Waiting for the pictures to understand better.

Repeating the request for pictures.

my right side doesnt sit 100 flat aswell had no issues i tried relevelling my table it worked but still a bit off. my concern is the smell thats escaping definetely contact support with images that will make things process faster

I’m sorry, I work on an ambulance. We don’t usually get to go home when we are suppose to. We aren’t that lucky. If no one shows up, no one gets to leave. I finally got some time off to take pictures.

Same problem, it’s the right side. The smell escapes after the exhaust fan shuts down, not during the operation.

Here is the picture without the lid held down and after checking the flatness and adjusting with an index card. The second picture is while holding the lid down.

Yup - lift the opposite corner and you’ll see that drop down.

This can easily be fixed with a couple of index cards in the right corner.

I will add more index cards.

This is going to happen whether your lid gets flatter or not - the GF isn’t designed to be airtight. The amount of gap shown in your photo won’t make a difference.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.