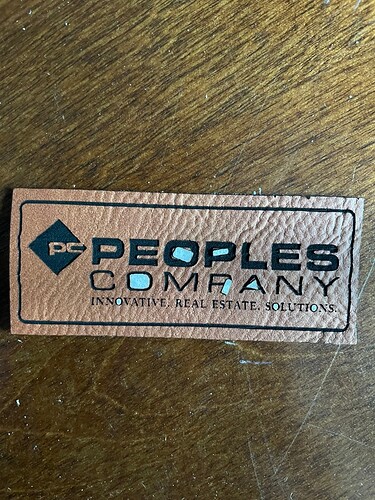

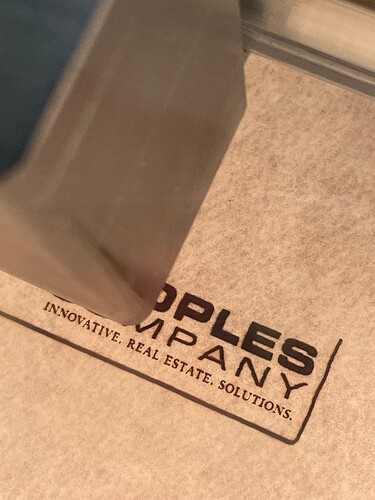

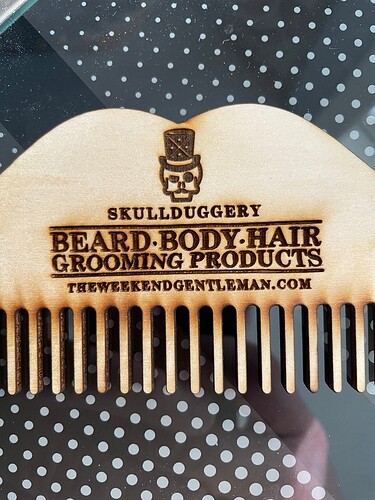

Hello, in need of help here. Recently when it comes to fine lines and details on areas I get uneven, inaccurate lines (pics Below) this happens on all media, wood, leather etc. A month or so back I had a carriage wheel crack and had to replace it. It was doing that when it started cracking. I replaced the wheel and a month later the other wheel cracked. I replaced that as well. It seems to be hit or miss where the lines are uneven or slanted. I don’t know if I should have replaced both at the same time or its something else? Tried cleaning the wheels and removing any dirt and debris. Please help.

I’m afraid you’re likely going to need to do an even more detailed cleaning. That kind of jumping is almost always debris or something breaking. Your examples both seem to be left-right issues, so I’d remove the carriage plate and belt entirely - check all the wheels carefully, and check the belt for cracked teeth. Also verify that the wheels that hold the belt to the underside of the beam aren’t cracked, or sliding down their posts. With the machine off, move the head back and forth very carefully and see if you can feel where the jumps are happening, and then focus on what’s touching where at that point.

If it’s debris then a good cleaning can take care of it, but if it’s wear then you may need to replace other parts. If, for example, the belt was moving back and forth over a cracked wheel it’s possible those teeth were damaged in the process…

Two bits of advice…

If a wheel issue develops, replace both, never replace a single wheel.

If you’re print quality goes down after maintenance, check your belt tension and inspect the full length of the belt for abnormalities and wear.

thank you, that was super helpful… and makes sense. Appreciate that.

Will do… and thanks again… I learn new things I am doing wrong every week.

but also things you do so SO right!

/uploads/db6859/optimized/3X/4/4/442b2237bef082ebec31bd6b47b168b59721558c_2_483x500.jpeg

hey thanks appreciate that.

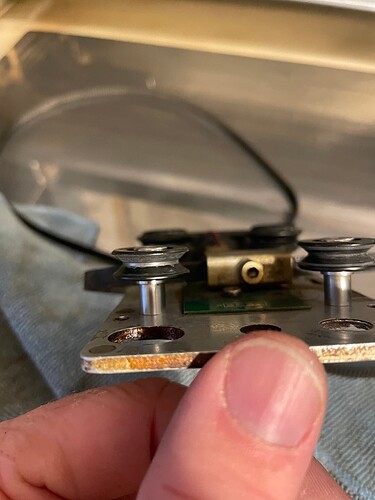

so i cleaned and cleaned and checked the belts, etc… i cant find anything off… but it looks like the one wheel might be worn down more than the other, is that possible or even a thing? Pictures attached. I have a feeling its because I didn’t replace them both at the same time like you said above… is that a fair assumption? Still waiting on Support.

The second picture shows what appears to be some sort of debris that is caked on the upper surface of the ‘V’ notch, which would definitely impact the accuracy of the wheel and affect line quality.

The wheels have a circular ridge, or bump, on the face of the ‘V’, it’s clearly visible on the right wheel in the second picture. This is ridge is the primary contact point of the wheel on the aluminum rails, it’s supposed to be the only point that actually contacts the rail, to limit possible disturbances from buildup and particles moving through the Glowforge cabinet during the laser process. The left wheel looks like it’s been sitting at an angle for some time, I’m assuming that it was the one replaced first, and may have lost the ability to track correctly, at least until all the buildup has been cleared from the face of the ‘V’.

Hello,

My name is Mercedes and I’m part of the Technical team here at Glowforge.

It looks like the forum folks have been excellent in helping you figure out this problem already!

It looks like you already have an email ticket, and so I’m going to go ahead and order those for you via that ticket.

I’m going to go ahead and close this forum post now. If you have any other questions or need help with anything else feel free to send a message our way by either creating an email ticket or a new forum post!