Illustrated:

Most of it. I use it for cutting miniatures. There are void pockets from glue, but I find those with a bright light first, circle them, and avoid them when I place the files. It’s not alot, and it’s a whole lot better than the more expensive boards I was buying from an etsy supplier. I get rolls of veneer there too.

I completely agree with using the light, although, all my dollars worked when I bought the supplies. None of my dollars had to be reprinted or numbers added to the paper. All my dollars worked perfectly. That’s what I expect from the suppliers that I buy from. Their product must work as well as my dollars. That’s what my clients expect from me.

I’m completely confused by the comments about voids. Only the very lowest quality Baltic Birch is allowed to have voids. Otherwise, each inner layer is a solid sheet of wood and knots in external layers should be patched. The whole point is that it’s used for things like cabinetry, where you may actually see the edges of the wood. Having voids on an edge would be unattractive. If you’re getting “Baltic Birch” with voids, you really need to take it back and complain.

You are so right about complaining and, I have.

Here’s the issue. IR lasers have various power settings. Full power 40 watt laser with a 0.012-0.015 focused beam can make it through 1/8" Baltic Birch at about 240 speed on a Glowforge. There are 3 layers to the BB I’m using. When the path of the design is laid over one of these obstructions, knots, fillers what ever, the density of the wood increases beyond the power of the lasers cut ability. I’ve done 7-8 passes over some 1/4" stuff and it barely makes it through. (remainder of the work piece is toast though). Looking for a cost justified 1/8" and 1/4" Baltic Birch, or comparable, that has integrity through the board.

I have the same laser so I understand the challenges with voids and knots. I have some ply that I’ve tucked away for other uses because it’s a nightmare to cut.

Honestly, I’ve never experienced anything like that in the Baltic Birch I’ve used. I had ordered some from Woodpeckers on Amazon and the first batch was fantastic. The second batch was not great so I stopped buying from them (it was warped and looked like lower quality). The last batch I bought was from Boulter Plywood and it’s been fantastic. That said, they aren’t cheap and shipping will certainly make it far too pricey for your needs.

I think you’re too high. Even with a pro.

Do a proper cut test to find the upper maximum and then step down the speed for reliability. Speed without reliability is not a win, you waste way more time and materials with missed cuts.

I tend to cut mine (0.125” bb) at 205/full/1x (pro).

Like any analog thing (plywood) there are variances. I’ve had BB range from 0.130” to 0.118” thick. I just hit it all with 205 and move on, life’s too short to wrestle with settings.

you can’t have an outer layer be baltic birch unless the inside layers are. it’s either BB or it’s not, all the way through. if they’re talking about it being BB inside as well as outside, I’d presume they’re either full of ****, don’t know what they’re talking about, or they think you don’t.

I’m certain it’s BB through and through. The center layer, that’s the layer with all the knots in it.

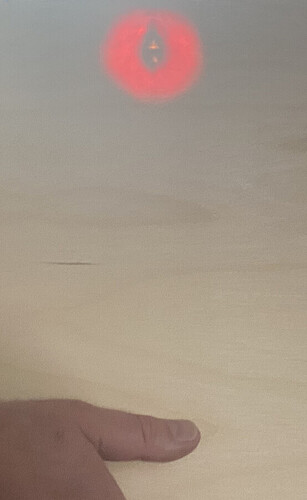

In the image, big ol’booger in the center of the ply layer. The outer laters of the board are gorgeous. I want the center layer to be the say as the outer layer.what grade is it rated at? it can be B, BB, CP or C. you shouldn’t be getting anything but B or BB.

B/BB & BB/BB. according to the suppliers WEDSite.

I didn’t see it linked so I’ll also point another Glowforge user is just starting a supply business

For whomever is interested, here is some interesting info about the standards for Russian plywood including Baltic birch.

In a nutshell, not every supplier is equal. For example,

4.1.1. The following species can be used for the face veneer: birch, alder, maple, elm, beech, aspen, poplar, lime. For core veneers, in addition to the ones just mentioned, the following can be used: pine, spruce, fir, larch and cedar.

The timber used for face veneers of plywood determines the species of the plywood.

The plywood can be made of one or more than one species of wood, therefore it is either “homogeneous” or "combined"

And, 4.1.3. Wood and manufacturing defects, exceeding the limits stated in Table3, are allowed in core veneers, as long as they do not influence its integrity and dimensions. The requirements for quality and dimensions are specified in this standard.

Could you share a link to that source?

Oops! Totally meant to do so.

Bought this many times on Amazon. It’s a little pricey, but you get sheets that are perfect for the laser.

I’ve avoided Russian sourced BB (although to be fair they do make larger sheets that are handy for cabinet makers). European spec BB cares about internal core composition.

Seconding Gabahl lumber for best priced true BB in SoCal. Rockler has great BB at slightly higher prices per sq ft. I’ve been intending to check out Cherokee Woods in Upland - they have a larger variety of “laser ready” thin woods including BB.

I don’t really understand your comment equating your dollars to your suppliets in this case as BB isn’t manufactured specifically for laser cutting like GF Proofgrade or other laser specific materials.

This topic was automatically closed 32 days after the last reply. New replies are no longer allowed.