Hello all, I have been using the Glowforge to etch Anodized Aluminum, steel masks and PCBs for about 2 months. I was wondering if anyone has grounded their glowforge with a grounding strap or some other means?

Our product are static sensitive. I was think maybe a using an ESD mat but it will have to be really thin because one of our products is close to the 2" max thickness.

I will post pictures after I get approval from the top.

Thoughts? Have a good day!

Karl

The machine is already grounded, all of the exposed metal components are directly connected to the earth connection.

The exception is the crumb tray, which sits on rubber feet and is mainly constructed from plastic. So you could make up a short ground lead from the aluminum frame to attach to it - a magnet would probably be sufficient. I suggest at the rear, as anywhere else would interfere with any proofgrade-sized materials.

Thanks, that is something we will probably do. Just in case.

Perhaps I’m unlucky, but my unit has a current leak between the lid and adjacent main body; when it’s operational I can feel a small amount of current moving through my hand if I rest it on the metal edging strips at the front edge. I have no idea where I put my multimeter, but if the kiddo behaves in virtual school today I’ll see if I can find it to measure the leakage.

It’s definitely a noticeable current; feels like ants crawling along my skin as long as I bridge the gap.

Dude. Stop using it, and talk to support. Email them at support@glowforge.com. Opening a P&S thread will just be a lot of noise from chupacabras (like me!) that can’t help you.

Eh, it’s not so bad – the issue has been around since the beginning (iirc, there are some pretty early threads discussing it).

I was mainly mentioning it because it’s another possible source of current that folks may want to deal with if they’re doing things with ESD sensitive targets.

The exposed metalized components of the lid and side panels are electrically insulated from the machine and ground.

At least supposed to be…

Somehow I doubt that glowforge’s lawyers would agree with you.

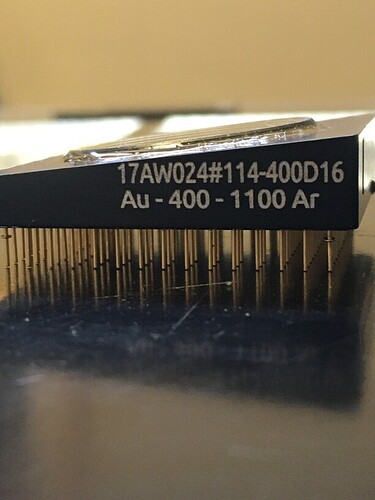

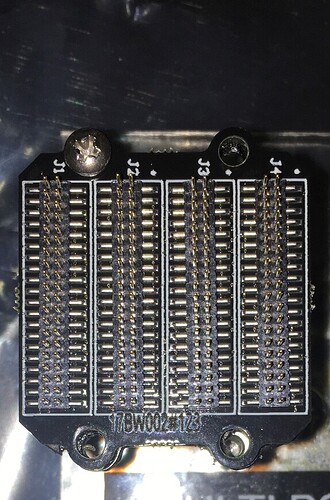

One of our engineers gave a thumbs up a long as the Glowforge is plugged in. So here are some examples of what I am etching. We are using the Glowforge to better identify our Deformable Mirrors by etching serial number, logo and other information on the anodized aluminum. We are also etching on PCBs. *note burn mark is from epoxy that dripped over the edge when we were sealing it. I should also add these were test subjects.

lol… laser for making tools for laser…

But, of course!