That’s awesome! And yes, I had the same trouble with the hinges being too tight, I’ve narrowed it down to the holes on the box being just a hair too close together, like, a kerf width maybe is all, but it also depends on the exact thickness of material used. But it’s just enough too tight that it puts a little too much pressure on the parts that rub when it opens, and the outer parts of the hinge will flange out a little if it’s too tight.

The engraving of the edges I think looks nice, and would work well if you adjusted for the thickness. Mine was a score line to separate the edge from the middle and used dark brown maker to color the edging to try and match the color of the cut edges.

Great job, keep experimenting! Everyone can always use a good box for something!

4 Likes

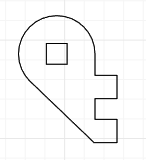

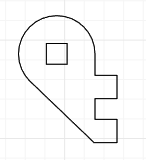

Cool hinge design! So you use a square shaft,

and on one side of the hinge it’s snug,

and then on the other side of the hinge it’s round,

Sorry I’m just catching up to this thread

And the issue is with the round hinge part? Hard to tune it so it’s not too tight or too loose?

4 Likes

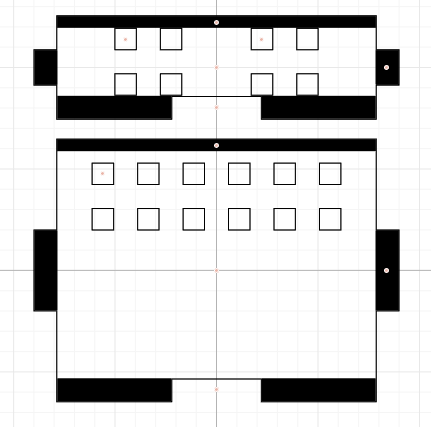

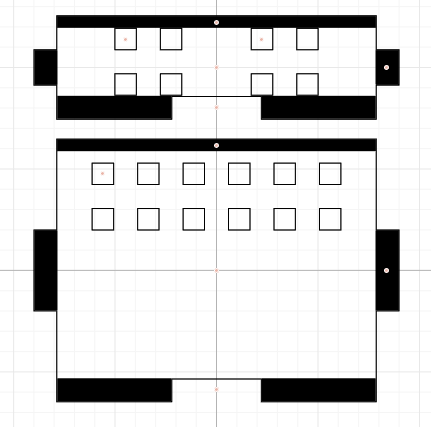

yup, that’s pretty much it, generally I do four with the square hole on the bottom and two with the round hole on the top, with two square ones in the middle (bottom, top, bottom, bottom, top, bottom). The tightness mainly has to do with the spacing of the holes in the piece they attach to. This particular hinge had 7 along the bottom and 4 on the top (b,t,b,b,t,b,t,b,b,t,b). The seam where the lid and box separate is at the same height where the middle of hinge bar is, if that made sense.

2 Likes

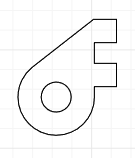

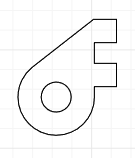

I see. So it’s not the size of the circle on the round hole that’s the issue, it’s how tight the “sandwich” is, which would be sensitive to material thickness. So on @jestelle’s design, that would be the spacing of these holes,

(Though @jestelle has a slightly different hinge — 6 on the bottom and 4 on top — b,t,b,t,b,b,t,b,t,b)

Thanks for sharing your experience. I haven’t designed any hinges like this but good to learn the pitfalls ahead of time!

2 Likes

The actual tightness on mine is actually pretty good now.

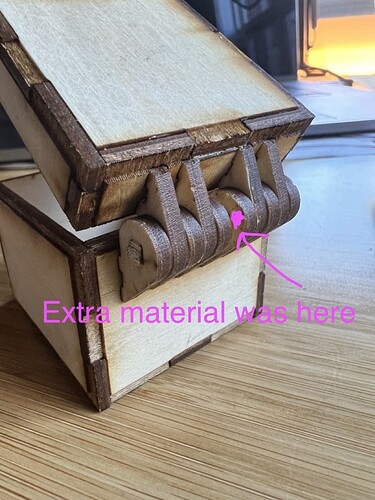

The tightness that caused me to damage the lid a bit was caused by having jammed an extra bit of material inbetween the two hinges (see picture)

I had jammed something in there when I was trying to get the shaft pushed through the whole thing to support the hinge so I could push it through. This helped, but I still ended up breaking the shaft in half and pushing it in from either side.

Next time I’ll cut two shaft pieces.

Then I tried to open/close the lid before I took that extra bit of material out, and I think with it in there, it just increased the pressure on everything such that it was way too tight.

With it removed, it’s actually pretty good.

So maybe next time I’d do the hinge exactly the same, split the shaft into two shafts for each 2x3 hinge part, and make sure I remove the spacer before I try to open/close the lid.

I also wonder if it might be easier to construct the hinge before attaching it to the box. I might try that too.

4 Likes