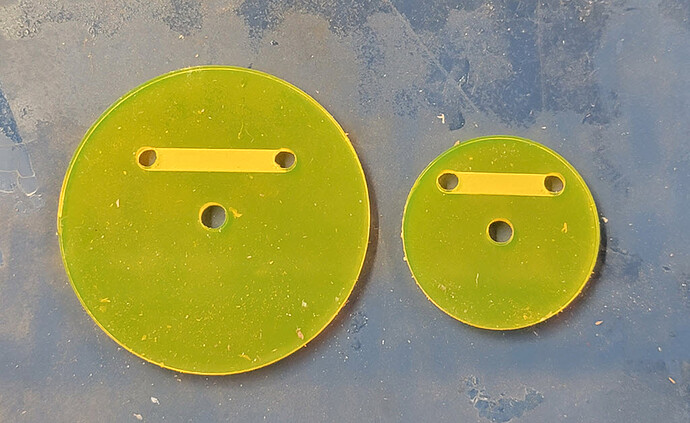

What the heck is THAT thing? A deformed smiley emoji? A pig wearing a mask over the eyes? An off-center button for off-center people?

Well, it’s for woodturners and it’s one of those tools that is so simple I wasn’t planning to post it. But the response to the last woodturning tool was so enthusiastic I figured I’d go for it. Y’all have nobody but yourselves to blame for encouraging me.

By the way, until today this was just two cut circles but but after many arduous minutes slaving away in Inkscape, I now present to you the DELUXE upgraded version, now with more holes! I’ll explain that later but for now let’s see what it does.

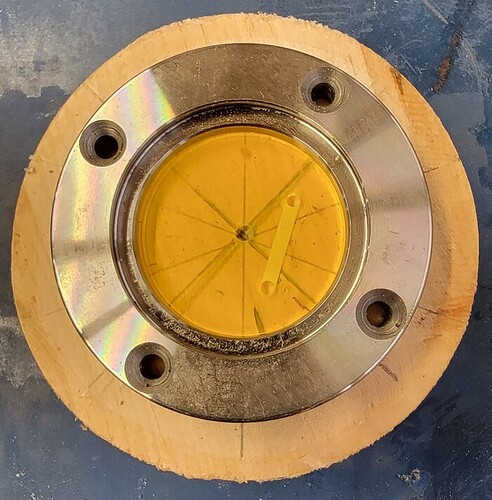

Let’s say you have an irregular-shaped piece of wood and you want to mount it on a faceplate. In this case this piece of cedar allows for a 4-inch wide turning at the top but a close look at the dashed 50mm line shows that a slight variation in any direction could reduce the total possible diameter of the finished piece considerably.

So there’s not a lot of room for error when attaching a faceplate ring, but at least with a ring it’s easy to see what you’re doing.

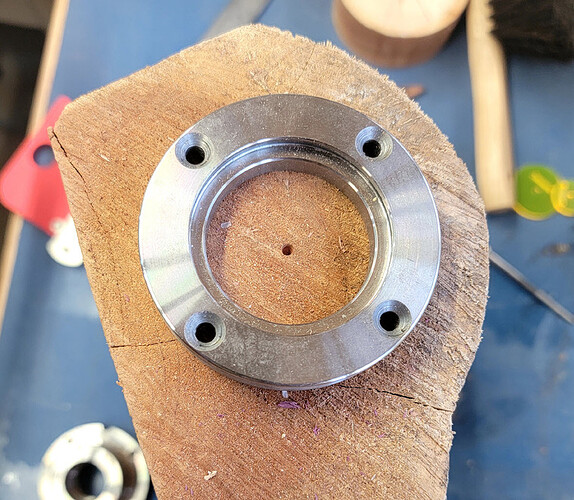

A threaded faceplate is worse. The center point is at the bottom of a small well.

But with this tool you just tap your awl, or a nail, into the center hole through the tool and drop the faceplate ring over it. Boom. Problem solved. Now drill pilot holes and screw the ring on. The faceplate or ring will be close enough to dead center every time, resulting in getting the most diameter possible from the workpiece.

Slightly tighter fit with the threaded faceplace so first position the faceplate, next drop the tool in, then find the center hole with the awl. A nail is much tougher to use here but a stiff wire would work. It just needs to find the center, not hold against torque.

It’s even more critical when mounting a faceplate or ring on stock that is already round or close to it. The least amount of wood is lost when the faceplate is mounted dead center. Any deviation causes that amount X 2 to be lost. If the faceplace is 1mm off center the largest diameter is reduced by 2mm. I used a small piece here to show the other issue which is that the screws used here will protrude 1/4 " into the workpiece. I can still make a usable dish or bowl though because the sides are far enough from the screws that the screw holes will be cut away when I dish out the interior. But there’s very little wiggle room so if the ring is off just a little I’ll hit those screws with the chisel whilst shaping the exterior. Probably at 1200 rpm.

So here’s the file for the tool. The larger one is sized for a Nova 50mm faceplate ring and the smaller one fits anything with a 1.25 x 8tpi spindle. It is easy to ungroup and resize the outer circle to match any needed size. There are only 3 common spindle sizes but many different rings with differing center hole diameters.

The cut lines are in different colors so the user can make the large cuts the last cuts. I hate it when the piece is cut out and drops a bit before all the interior cutting, engraving or scoring is done.

The two “eyes” and the engraved line connecting them is something I just added because I got tired of turning the workpiece upside down and shaking it like an Etch-A-Sketch to get the tool loose. The idea is to loop a sturdy thread through the holes to lift the tool out after the faceplate is attached. The engraved channel allows relief so the thread doesn’t wear away. My plan is to glue the thread into the channel.

I recommend a translucent colored acrylic for this project. You want to be able to find it in the drawer but you also want to be able to see through it to help find the center hole that was punched in the first step.