An Electronic Resource for Miniature Builders!

@tjleasa made such an incredibly timed post becasue just yesterday I spent a solid 5 hrs trying to sort out servo motors, step motors, arduino boards etc, and while I have a tiny bit more clue, it aint enough to get what I need. So I’ll take tjleasa’s cool resource post as a sign I should figure this out and work on the concept that’s been floating around my head for years, and was the very idea that prompted me to get a GF in the first place. So if anyone knows enough to take pity and help me figure it all out, I would be so grateful. I am not electronically inclined and every time I try to figure out how to go about it, I get so frustrated I just give up for another year.

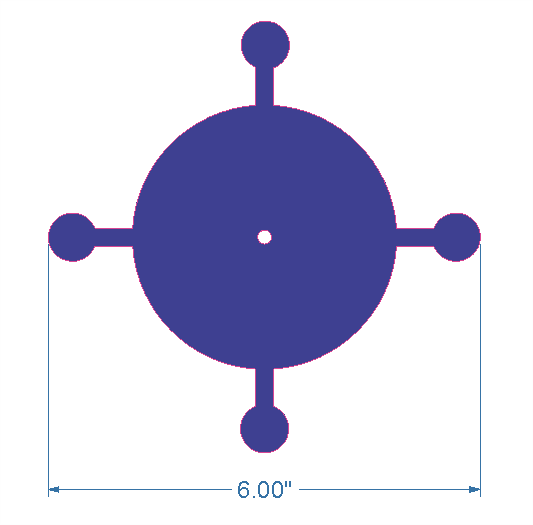

I know I need the motor and maybe a control board, and I now have a very general understanding of how an arduino board works, but that’s about it. What I’m looking for is a motor that can spin a 6" disk of thin acrylic or wood, and I want to have it mounted in a frame behind the disk. I want to power it via a regular plug or usb with just a simple on off switch. It can’t spin too fast and one speed is fine, but in a perfect world it could have a knob to control the speed. (I can live without that though.)

-Which would be best; a step motor, servo or maybe a little brush motor?

(What I’d really love is to figure out using a servo so I can make more complicated kinetic sculptures and automata, but I’ll start off small first lol.)

-What size motor would I need; how do I know what power/torque I’d need?

-If I need a motor with a control board, does the power and on/of switch work off the same board, or is the board only for programming the motor?

-What exact components would I need? (Board, wires, switches?)

or

-Anyone know where to just get a kit that has it all together or a place that lists exactly what components go together so beginners like me can sort it out? (I couldn’t find any, but I don’t know what I’m looking for, so… ![]() )

)

I make it this far, but then it all turns into Greek and I don’t know what I need or which kits may apply.

Here’s what I’m trying to spin

And I know I want it to spin between 15 and 25 Rpm, so now I’ll figure out the torque I need to sort out which motor would work and that’ll give me a great starting point. And if you and

And I know I want it to spin between 15 and 25 Rpm, so now I’ll figure out the torque I need to sort out which motor would work and that’ll give me a great starting point. And if you and