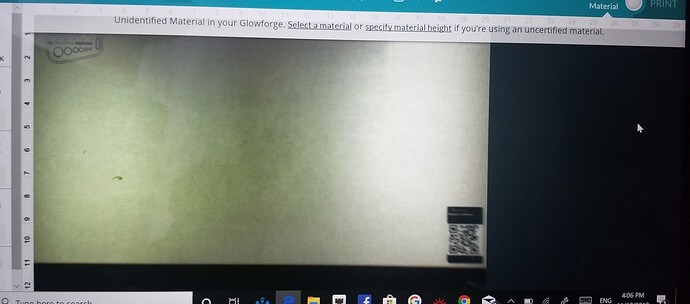

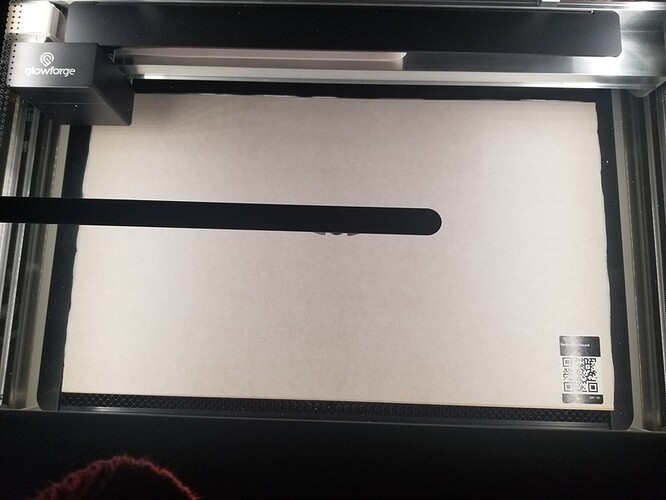

I am ready to use my GF for the first time and it is not reading the proofgrade materials. I am just starting with the simple key chain ruler and the draft board, but it seems not to be working no matter what I do. I get a message telling me I am using an unrecognized material. The proofgrade bar code sticker seems blurry on the computer screen. I tried by cleaning the lenses and nothing has helped. Any help will be greatly appreciated.

Just select it from the “select material” option in the top left corner. You can ignore the warning if you are using Proofgrade materials and their settings.

I will try, but why is it not reading the bar code?

Reflected light, code in the wrong position (too close to the edge), etc. It’s nothing to be concerned about.

Thanks! Just finished with my first print!

You can try flipping the board around so the code is in the upper left as well and see if it will read it. Doesn’t matter if it’s upside down or right side up. But the lid camera uses a fisheye lens and as it gets further to the edges it gets blurrier. If the tag is too far outside, it will not read sometimes. As eflyguy says… not a big deal.

Probably because it’s blurry. A lot of ours are, but as he said just choose from the list. When I first got mine years ago, I went to the trouble of cutting the code out for each material so I could just drop it in for a remnant that didn’t have it.

I never worry about the code anymore. Get to laserin’ Girl!! - and enjoy the adventure!

Congratulations! We look forward to seeing your projects.

Yes. This sheet really does have it at ththe edge.

Congrats on doing your first print!

Maybe they should start putting those bar codes closer to the center of their sheets. A lot of complaints about this lately.

Then you waste a large portion of the material, or struggle to work around it. Those stickers don’t remove from the masking easily.

Perhaps the solution is to make the stickers easy to remove and relocate?

(or just ignore them and manually select)…

^^^^

I often take them off with a blade or flip the material over. They are more of a hindrance to me at this time.

Thank you! Very exciting process…can’t wait to see finished products soon.

That was supposed to be the ultimate plan.

Welcome to the group! Have fun with your new machine and make sure and share a project or two so we can see what your making. FWIW, I intentionally turn over material so the sticker is on the backside anyway. It seems like it wouldn’t matter, but the thickness of the sticker is enough to change the look of engraving. Lasers are very exact and the smallest fraction of thickness or measurement can effect the outcome.

Unlikely. Many people have their machines get stuck on centering or similar because of material on the bed. Having the code all over would likely make that a much more common occurrence.

Perhaps. Guess I’m just lucky, I’ve never had either machine I’ve used not calibrate successfully regardless if there is something on the bed.

I wish everyone’s worked as well as mine has. For that reason I can’t help but think most of the problems would be environmental.