I am having issues with cutting 1/4" maple plywood. Sometimes it cuts all the way through and sometimes it doesn’t. I can have several things on the same board to cut and some of them will cut and some will not cut. Some items cut part way and some all the way.

That’s the problem with plywood. There are voids filled with glue and knots on the inner layers which do not always cut through.

Proofgrade, or got it somewhere else?

It is Columbia Forest Products 1/4" PureBond Maple from Home Depot. Hundreds of people use it in the GlowForge groups and doesn’t have a problem with it. I have had problems cutting from day 1. Sometimes it will cut and sometimes it won’t. I am cutting some things on the woods that came with my machine today. I have only used the draft boards to do the first 3 projects that are in the set up. Then tried some things on the Maple. So far I am disappointed with my machine.

I understand, but why can hundreds of people use Columbia Forest Products PureBond Maple and cut all day with no problems and I can’t get hardly anything to cut. That is what I don’t understand. Why it works for some machines and not mine.

The troubleshooting guide up above is key, as is the testing link I posted. I can think of lots of reasons why you’d see inconsistent performance, anything from “you get weird batches of ply” to “your store your materials in a high humidity environment” to “you are using the incorrect material height” to “you are using recommended settings on a basic that were meant for a pro” to “you haven’t cleaned your optics properly lately” to “you have your lens in upside down” to “you have junk under your crumb tray” to “your gantry is misaligned”… and on and on.

You’re just asking a very complicated question and not giving enough detail to really answer it. You’re going to have to do more work to dial in off brand materials, only proofgrade is plug and play. Off brand stuff is less expensive but it puts a lot more onus on you.

… also not for nothing but while quarter inch is possible a 40ish watt laser is really in its sweet spot at 1/8”. I like to combine two layers to make 1/4” after I cut them. In no way am I saying it can’t do quarter inch, but it’s always a bit tougher to get it right.

It’s also possible that you unluckily got a poor batch of the Purebond that has more knots/glue than usual. Natural materials are difficult that way.

Thank you, I appreciate the feedback. I opened a new box and just tried it. It was cutting, but here is what I have now. My screen, then the wood in machine. It started cutting in the center and when it went off the wood onto the crumb tray I click the button to stop it. Now what? It was actually cuttin all the way through so maybe my order of the 3 boxes I have tried have been some bad pieces and some good. I don’t know but why is it starting to cut in the center and not on the left?

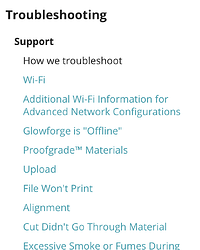

The troubleshooting guide talks about this I think.

best cases:

- Your material has inconsistent thickness.

- your crumbtray isn’t level

- your material is warped and not totally flat on the tray

Worse cases:

- Your crumbtray is not flat, and has some defect

- Your laser alignment is off and so you see problems as you go to the edges of your material

We’ve given you all the info you need to work on this, between the hints we’ve given you and the troubleshooting guide, you’ve just got to go through it I’m afraid. You’re asking us to spend our time making wild guesses, that’s not good for anyone… we spin our wheels and potentially lead you down dead ends that you may or may not have already ruled out.

Unfortunately, there’s no substitute for doing the proper troubleshooting process, all we can do is speculate.

It’s been mentioned before but nobody pasted the link (mostly because it’s really easy to find) but if you are having trouble finding it, here you go:

I am so sorry for all the trouble. I have followed the guide and have tried everything. Sorry for all the inconveniences I have caused all of you…

No no, it’s no inconvenience, I’m just saying that it’s tough for us to get to the bottom of your issue from far away like this. Did you take a step back and do a test with the gift of good measure (aka GOGM) on draftboard yet?

One thing they’ll (support) want you to try is to cut that on the right edge, the left edge, and the middle.

If you get solid results with the GOGM in your tests, then it starts to seem more like your material than a problem with the machine. Like several people have mentioned, plywood can be inconsistent.

If your GOGM results don’t work well, I’d say it’s time to open a support ticket. I’d keep notes about the times that you do your tests, it’ll help them track it down in the logs.

I have a support ticket and have done tests and cleaning and sending pictures of everything to them. They told me to post here. It is okay, I think I am done with it. Only had about a month and nothing but inconstancy from the beginning.

Well, I can say that once you get dialed in it’s an amazing tool. I suppose it’s not for everyone, it does require a bit of work to get the most out of it, especially with 1/4" off brand materials.

That being said, there are so many things it can do that are surprising and fun. Hopefully you’ll turn it around, but if not, it sounds like you’ve given it a good try.

Glad another piece of material is working better for you.

I’m not sure I entirely understand your new problem, are you saying it’s cutting more than 1/4" off from where it shows on screen?

If you’re getting a large offset you didn’t have before it’s possible the head got bumped and no longer knows where it is.

Try turning off your GF, then gently move the gantry all the way to the back and then the head all the way to the left before turning it on again.

Thank you.

Glowforge can’t provide support for non-Proofgrade materials for exactly the reasons that you are listing. Those products are just too inconsistent.

There are a couple of tricks that you can use to get better cuts on that kind of product and that might be why they sent you here…

Check the boards before you try to cut them. If you see gaps in the fill at the edges, it’s not going to cut all the way through. Air gaps are extremely common, and they don’t burn. (No fuel.) You can mark it with a pencil and avoid placing a design in that spot.

You can check for other air pockets and glue plugs inside the board by shining a strong flashlight through it from behind…you can see the gaps and heavy plugs. Mark those and avoid them as well.

And dodge any surface knots that you see - those are too dense to cut without a lot of charring and damage.

The problem is no doubt with the material. I’ve bought Home Depot plywood, and I got rid of it as soon as I could. Stuff is an absolute bear to cut consistently. (It wasn’t the Pure Bond variety, but if you are buying cheap wood, you’re going to have a lot more trouble. That plywood is not for lasering, it’s for construction, and air pockets and glue plugs don’t matter when you are cutting them with a saw.)

If you can get it, you’re going to have much better results with Proofgrade. Since that is not as available right now, you might have to check your wood a little more carefully before getting started.

Definitely a pain…I hope they get more Proofgrade stock in soon, but everyone is struggling with the virus related issues right now.

Second best choice is real Baltic Birch plywood, and that still needs to be checked, but it tends to be more consistent and slightly better quality than the kinds at the local hardware stores.

Anyway…it’s tough to try to get started learning the machine with non-PG materials.

Thank you