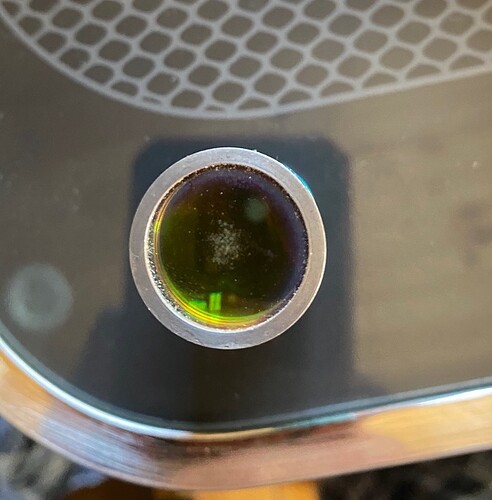

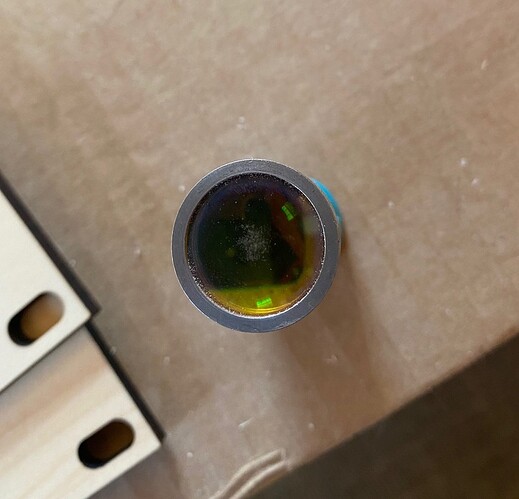

So I’ve been having consistent problems with my GF not fully cutting though Proofgrade materials. The GF I have now was a refurb I received in November 2020 after my previous GF was determined to be unfixable. Just today, I’ve gone through three Proofgrade sheets @ $20/sheet. Over the past several months I’ve completely cleaned the machine, all mirrors, lenses, etc. Again, today I took out the lens, the mirror and checked the little circular window on the printer head. All three appear to have scratches in the center. I’ve attached photos of all at different angles to try to show the scratching. I used the Zeiss cloth only to gently clean the surfaces, but the scratches won’t go away. Is this something that needs to be addressed? Is the scratching normal. I just don’t know what could be causing the machine NOT to cut through the material. Any suggestions would be appreciated. I;'ve wasted sooo much time trying to get this machine to work as it’s supposed to. I think this is my 4th Glowforge. I don;t recall this same problem on any of the others.

That’s from not cleaning them often enough. Soak a soft cloth in isopropyl alcohol and hold it against each lens for 30 sec or so, and see if you can wipe it off. It doesn’t look to me like it’s gone long enough to cause permanent damage; fingers crossed!

Aha Genius!! I think the Zeiss wipe I used (my last one) felt a little dry. Used the alcohol and all the markings came right off! Just ran some prints using different materials, thick and medium, as well as draft board…and everything is cutting just fine.

How often should the lens and the mirror be cleaned?

Everyone has different requirements based on the material they cut and how much they cut. Check them on a regular bases and clean when necessary.

Whenever they need it. ![]() I do them any time my cuts stop going through on known settings, or when I can see any fogginess developing on the windows inside the left side of the GF or on the left side of the head, or when I’m starting a new project that I really care about.

I do them any time my cuts stop going through on known settings, or when I can see any fogginess developing on the windows inside the left side of the GF or on the left side of the head, or when I’m starting a new project that I really care about.

Thank you all for the info! I’ll be setting up a regular maintenance schedule. Appreciate all the feedback. Nice to be back in business!

If you look through the lid while a job is running, you’ll be able to see the window on the left side of the printer head as it moves around. If there’s a little circle of dust in the middle, like in your photos, that’s when I know it’s time to clean. Since I watch every job start to make sure the machine’s doing what I expect, that’s when I check if it needs a cleaning after that job finishes too. If I’m cutting something like thick draftboard that burns pretty dirty, it could be just an hour or two between wipes. Since I use a variety of materials, a schedule doesn’t really work for me, I just have to keep an eye on when things are dirty or not.

I’m glad you resolved it! Thank you everyone for your advice. I’m going to close this thread. If you run into any other trouble, please start a new topic, or email us at support@glowforge.com. We’re here to help!