Yeah, I’m intimidated. I’ve had use of a PRU for 3 months now, and my design skills are nowhere near at that level. Like, not even close. I’m consistently blown away by everyone here.

you could just be crazy and try to engrave a shallow tray around the outsides…

Seriously, don’t be intimidated. I’ve designed tools that have built spacecraft for many years, and I review and (very much annoy young designers) models to this day. I’ve been playing with CAD since the early 1980s. It’s a different kind of thinking than Adobe Illustrator (which is, BTW, kicking my behind although I’m starting to get it).

I have no doubt I could make a mask. I wouldn’t be anything as fine as yours are to start, but I’ve got a lot of Mardi Gras behind me so I’m sure I can make something to make me happy (at least to start).

I’m consistently blown away and inspired by everybody here too. I love hanging around with artists, doctors, basically all of you because we do approach things differently. It’s all a great learning experience for me.

what hansepe said. what’s hard for people to remember is there are so many different ways to be talented and creative. so sometimes someone is way better at something you may not be able to do. that doesn’t diminish the cool things you do.  that just means your “cool” stuff is different than their “cool” stuff.

that just means your “cool” stuff is different than their “cool” stuff.

I heard “competition”!! ![]()

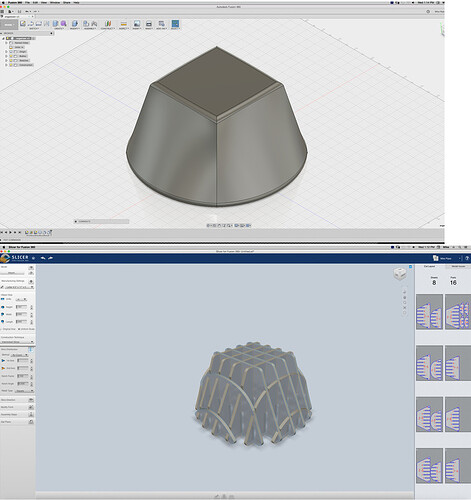

7min 11seconds. ![]() But I had the benefit of your design as a reference. However I could not just duplicate yours, so I used the Loft command instead so I could use a circular base.

But I had the benefit of your design as a reference. However I could not just duplicate yours, so I used the Loft command instead so I could use a circular base.

I have to admit though, that traditionally, if I wanted to make this final outcome, I would spend the time to model the finished item in Fusion. Using Slicer makes this so so so stinkin’ fast and I wouldnt have remembered to use the app because it just hasnt been in my regular workflow. I have to think about things differently now!

That was my thing too. When I saw @Jules add the challenge to her post I immediately thought of Slicer because I’d been looking for an excuse to use it. This was the perfect application. There are things I want to do better. I’m not impressed with the slots at the outer fiber, they appear pretty weak. So now it’s just tweaking and understanding the tool better.

I like the loft. If I’d seen @markevans36301 file first I’d have done some things different, and the discussion above makes round a better choice now too

Oh, and @henryhbk also influenced me with his “I’ll cut anything” attitude. I wasn’t going to print at first but then figured I’m already this far in, why not? I learned by printing that my calipers aren’t good enough (I found the better set now) and that explains part of the problem.

Draft material is micing out at .125 and PG Maply Ply I’m getting .127 to .129 so far. They are better calipers than the first set, but not good calipers

Your screen capture kind of weirded me out as it looked just like an early iterate of mine. We got there slightly different ways but that is fusion for you. (I used a loft)

I’m calling shinanigans! I’ve seen your work. Step out of that comfort zone and call me on it when I do the same.

That’s cute but until you cut you don’t know the problems and reasons to iterate.

Ha! Nope - unfortunately, I’m being very sincere. The fact that I am able to create pretty shiny things is (truly) due to: a) the simplicity of this machine and b) I’m adding a lot of hand worked details. Yeah, I’ve figured out how to use this tool to cut leather - which is great, since that’s my primary purpose - but seriously, how hard is that?

I guarantee you that if I sat down to create a functional 3-d object like the ones shown in this thread it would take me a heckuva lot longer than 10 minutes, and there’d probably be a good deal of cussing and crying along the way! ![]()

Working to change that, but it’s definitely a shift to go from designing by hand to designing via computer. It’s not just about learning software (though that’s certainly a piece of it) but about learning to look at things from a completely different perspective than I’m used to.

Ha! That is exactly how I know who is working and who isn’t ![]() That shows you’re into it.

That shows you’re into it.

LOL

Having been an Engineering and CAD Manager the last 10+ years, I’ve definitely heard lots of cussing and crying. Luckily, my employees have usually been good about talking me off the ledge. ![]()

I’m not going to tell you how long it took me or how much scrap I made to make the above. Point is you have talent and people who can help you with the rough parts. My primary asset is not knowing just how badly I suck so I keep trying!

Piffle again! Nobody sucks! We’re all just learning as we go. ROFL!

I threw in my lot with OnShape and have been working with that for my 3D models. The Kiri:Moto app does a great job at slicing a model for SVGs laser work as long as the slices are on one plane or your parts are laid out on one plane for assembly. I’ve tried to find something similar to Autodesk’s 123Make or the Slicer that has been added to Fusion 360 do do cross sectioned slicing at intervals for cardboard models or something like the Obelisk tool holder. Any leads on something like this for OnShape? Maybe there are settings in Kiri:Moto that I have not discovered. Thanks.