Hi,

We just got and GF basic and are very excited about it, and we’ve had some good prints already and some very helpful replies in the forums. But we are getting more odor than we would like in an extra room in our basement. I don’t believe this is in the category of “problem”–there’s not a lot of smoke or anything visible in the room or something that seems disturbing. But we’d sure like to reduce the odor. I’ve been trying to track the many venting threads, including those the reference external fans, but I still have lots of questions, and I’m hoping you might help.

In terms of our set-up, we’re venting out an egress window through a piece of plexiglass with a 4" hole in it, and we’re about eight feet of ducting from the back of the GF to the window. I know that I need to do a better job of sealing the plexiglass against the window, which I will do with some insulation. I also need to do a better job of sealing around the duct that runs through the plexiglass. I suspect addressing those issues will help. In the meantime, I am wondering about the following:

I’ve read several suggestions about various types of ducts that seem to be better than the one that is included because they are somehow quieter and less likely to let smells escape. I was thinking that I should go with this one or this one, though there was some debate about whether or not ducts that have a layer of PVC add to fire risks or maybe make any would-be fires worse. I’d be curious what your thoughts are here and to what degree that might help solve some problems.

I was also reading that external fans are a useful addition, but I was little unclear about three things:

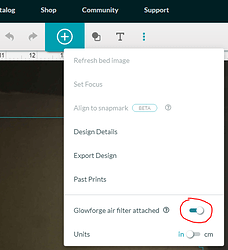

Is the idea to run the external fan WITH the built-in fan? Are there any risks to that? Does doing so compromise the warranty? I wasn’t clear if there was an internal fan shut-off that people switch off when using an external fan.

What size fan should I be using? Initially I was going to get something like this. But some posts suggested I need one that is at least as strong as the GF built-in fan (which I think is 200 CFM?) so as to avoid air actually being sucked backwards into the GF. Is that correct? Any recommendations on the fan? Ideally it would 4" but I don’t know if that’s doable. Again, we’re only going about eight feet with a couple of turns.

Finally, ff the addition of an external fan is recommended and doesn’t put anything else at risk, is it best to put it closer to the machine or perhaps into the plexiglass at the window?

Thank you for your thoughts here.

and the 2nd at the window. I can’t even smell acrylic anymore. It’s lovely

and the 2nd at the window. I can’t even smell acrylic anymore. It’s lovely